| Features : |

• Exclusive barrier screw design. Separate channels for melt and solid results into high output rates and good melt homogeneity at lower temperatures.

• Grooved feed bush in combination with barrier screw allows less material slippage |

| Technical Specifications: |

| Model |

:

BEX- 1- 90- 30 (B4) |

| Main Drive |

:

200 Kw AC Frequency drive |

| Pipe dia range |

:

250- 630 mm (OD) |

| Output |

:

600 - 700 kgs/hr |

|

|

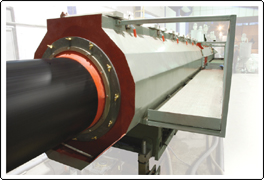

Innovative Spiral Lattice basket die head : PO 630/1100 vsi |

| • |

Consists of spiral for coarse distribution and a compact lattice for fine distribution of melt. |

| • |

Excellent wall thickness uniformity. |

| • |

Low pressure build up. |

| • |

Low melt temperature even at high throughput |

|

|

|

|

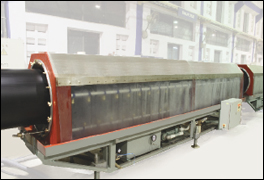

Vacuum Calibrator: V-630-6.0 W |

|

| • |

Offers superior quality production and greater cooling efficiency |

| • |

Precise temperature water flow and level controls through an inbuilt automatic system |

| • |

A stable vacuum facilitating quick pipe formation and reduced wastage |

|

|

Spray Bath : K-630- 6.0 W |

| • |

Optimum positioning of bayonet type spray nozzles |

| • |

Facilitates intensive cooling of extruded pipe |

|

|

|

Haul Off Unit: R 630/6 |

| • |

6 belt assembly. |

| • |

Accurate pulling force preventing ovality for large diameter pipes. |

|

| • |

Precise synchronisation between drives of haul off and extruder for ease of operation and reduction of material wastage. |

| • |

Pneumatic clamping for efficient traction of pipe. |

Cutting Saw: SU 630 P |

| • |

Planetary saws with hydraulic control. |

| • |

Silent pipe cuts without burrs . |

| • |

Adjustable chamfer sizes. |

|