It will lower the film cost by adding recycled & calcium field materials in

middle (B) layer & virgin material in skin layers

Increase the strength of the film by having multilayer film structure

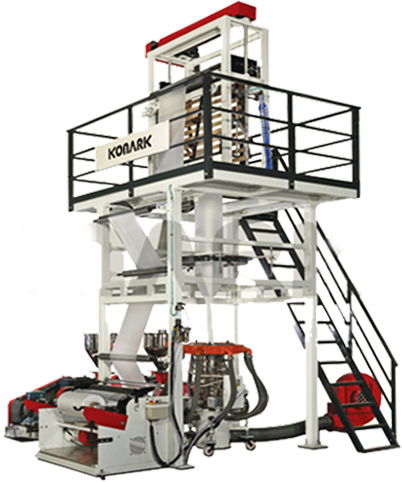

LEADERS IN PLASTIC EXTRUSION MACHINERY

Being a forerunner in the field of Plastic Extrusion Process

Technologies, for the last two decades, KONARK has

maintained its NUMERO UNO position by offering the latest

technologies & widest range of Thermoplastic Extrusion

Machineries

Technologies, for the last two decades, KONARK has

maintained its NUMERO UNO position by offering the latest

technologies & widest range of Thermoplastic Extrusion

Machineries

THREE LAYER BLOWN FILM PLANT : A-B-A TYPE

A FURTHER INNOVATION FROM KONARK…..

Why A-B-A ??

Applications

Shopping Bags / Carry Bags D Cut Bags Garbage Bags Liners

Features

Compact dimension results in minimum space requirement

Nitrided screw & barrel made out of special nitro alloy steel

Specially designed spiral type fix die head & die ensuring uniform flow

distribution with better thickness control

Candle type filter changer

Uniquely designed air cooling ring for higher output

High density ceramic band heaters

High output with less power consumption

Bubble guiding basket / irish ring

Guzzeting attachment

Single station surface type winder

Nitrided screw & barrel made out of special nitro alloy steel

Specially designed spiral type fix die head & die ensuring uniform flow

distribution with better thickness control

Candle type filter changer

Uniquely designed air cooling ring for higher output

High density ceramic band heaters

High output with less power consumption

Bubble guiding basket / irish ring

Guzzeting attachment

Single station surface type winder

Optionals

Embossing Roller Auto Hopper Loader Corona Treater Air Shaft LD/LLDPE Attachment