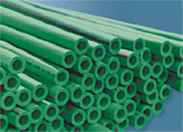

Water utilities need pipes that are corrosion resistant, smooth, friction free and resistant to bacterial growth. PP-R Piping Systems are now being preferred as they have all these qualities, besides being easy to handle and install, with high long term reliability. The construction boom has fueled demand for PP-R Pipes, especially for hot and cold water distribution and supply applications, leading to demand for Masterbatches for PP-R pipes.

|

||||||||||||||||||

Range of PP-R Masterbatch Products

|

||||||||||||||||||

PBI, India’s largest manufacturer of Masterbatches produces Special Colour Masterbatches for use as colourants when manufacturing PP-R pipes. These Masterbatches incorporates PP as Carrier Resin, which provides excellent miscibility with the PP Resin. The Masterbatches also have special pigments with greater stability to provide uniform and excellent colouring quality to the final product. PBI also produces an Antioxidant Masterbatch (Antioxidant PR-R06) for processing stability during the processing of PP-R Pipes. An UV Stabilizer (UV Stabilizer PP-R13) is also available to protect PP-R pipes from degradation due to exposure to UV - Rays of sunlight. |

||||||||||||||||||

Rising Demand

|

||||||||||||||||||

Indian Market for PP-R Pipes is developing fast, projecting an encouraging 15000 Tonnes for 2007 - ten times that of 2004. European and Chinese markets are also showing high growth, with projected demand for 2007 in China itself being 158000 Tonnes. This means increasing demand for corresponding PP-R Masterbatches. PBI can meet this demand both qualitatively and quantitatively and provide all support for the increasing use of eco-friendly PP-R Piping Systems. |

||||||||||||||||||

|

||||||||||||||||||

| Masterbatches for PP-R Pipes | ||||||||||||||||||

|