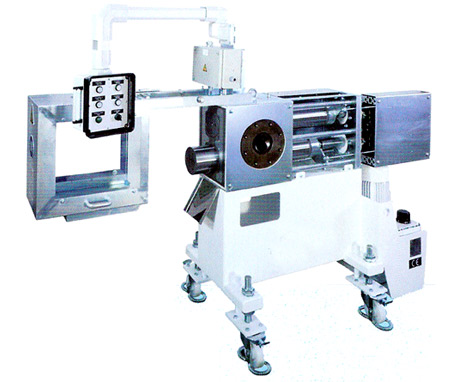

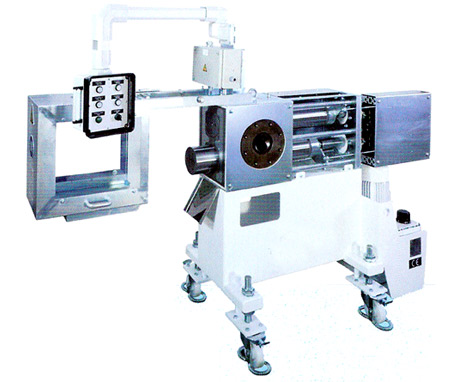

For Sale - AIE - 1726 - Screen Changer

Reference Numbers

AIE - 1726Product

Screen ChangerManufacturer

Germany

- Melt filtration for continuous operation

- Quality assurance

- Optimized utilization for the production capacity

- Reduction of down time and start up waste

Primary Applications: Our Systems are primarily used for melt filtration in continuous production processes

- Production - Polymerization-Processes

- Compounding

- Color - Additive - Masterbatching

- Profile - Pipe Extrusion

- Fiber - Production

Our Systems are suitable for almost all thermoplastic-processing applications:

PA, PE, PP, PET, PS, PC, POM, ABS, SAN, EVA, PIB, Hot Melts

Throughput Range: 20 - 20,000 kg / hr

Screen Area: up to 4,880 cm2

Special Design Features of our Screen Changers: The Filtration systems are designed for an optimal integration into the production process.

- Compact design due to optimal screen surface area vs. bolt diameter

- Low melts volume in the screen changer

- Short residence time in the screen changer

- Optimized flow channel geometry

- Venting of the cleaned screen cavity

- Ergonomic design, easy to operate

- Screen changes without interrupting the melt-flow and production

- Robust

- Low maintenance

- Longevity

Process Optimization:

- Reduced pressure drop

- Largest possible screen area

- Reduced product shearing

- Minimized melt temperature change

- Process oriented design

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}