For Sale - AIE - 3263 - Temperature Controllers

Reference Numbers

AIE - 3263Product

Temperature ControllersManufacturer

Dynisco - Manan Enterprise, India

Dynisco Range of Temperature Controllers:

1) TCS:

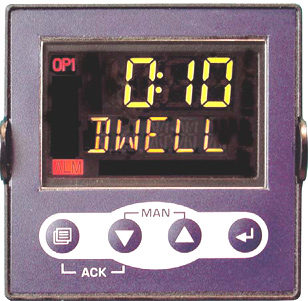

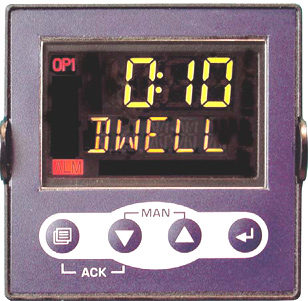

Dynisco's all new TCS (1/16th DIN) temperature controller is a powerful heat/cool controller that provides a new level of user convenience designed to meet the demands of sophisticated temperature control while maintaining user - friendly operation. Combining traditional control methodology with modern artificial intelligence concepts, the TCS continually adjusts its control strategy to provide precise temperature control.

The new three color display provides clear indication of process variables. The upper display shows the process value while the lower display can be set to indicate a range of parameters including, set point, time remaining and load current. The operator interface is fully customizable enabling any parameter to be promoted for immediate operator access. Scrolling text display messages may be up to 127 characters in length.

Field configurable for sensor type, temperature scaling, and heater current measurement capability combine to make the TCS an extremely versatile temperature controller.

Features:

- 1/16th DIN mounting

- Intuitive color display with text messaging

- Universal process and TC/RTD inputs

- Multi-function ramp-dwell/process timer

- Soft start output power limiter

- Up to 4 control and alarm outputs

- Load current display and fault monitor

- Up to 3 logic inputs

- Serial ModBus communications options

- Digital retransmission

2) TCE

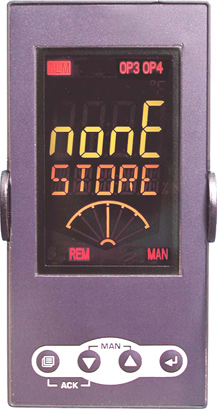

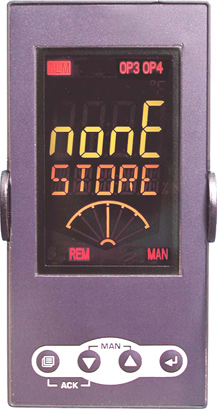

Dynisco's all new TCE (1/8th DIN) temperature controller is a powerful heat/cool controller that provides a new level of user convenience designed to meet the demands of sophisticated temperature control while maintaining user - friendly operation. Combining traditional control methodology with modern artificial intelligence concepts, the TCE continually adjusts its control strategy to provide precise temperature control.

The new three color display provides clear indication of process variables. The upper display shows the process value while the lower display can be set to indicate a range of parameters including, set point, time remaining and load current. The operator interface is fully customizable enabling any parameter to be promoted for immediate operator access. Scrolling text display messages may be up to 127 characters in length. The TCE provides additional graphic analog indication of OP power, error and heater current.

Field configurable for sensor type, temperature scaling, and heater current measurement capability combine to make the TCE an extremely versatile temperature controller.

Features:

- 1/8th DIN mounting

- Intuitive color display with text messaging

- Universal process and TC/RTD inputs

- Multi-function ramp-dwell/process timer

- Soft start output power limiter

- Up to 4 control and alarm outputs

- Load current display and fault monitor

- Up to 3 logic inputs

- Serial ModBus communications options

- Digital retransmission

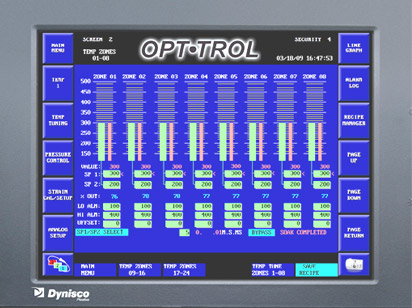

3) OPT-TROL Melt Control System:

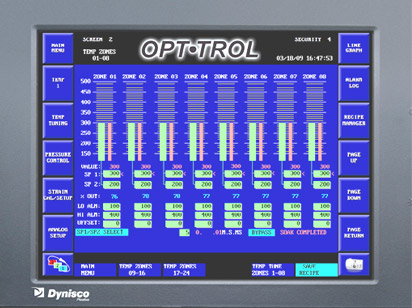

OPT-TROL (optimal control) is a true plug-and-play system specifically designed for small extruders, but includes features found in larger extrusion control systems. Auto tuning temperature control with two low current 24Vdc outputs will allow all zones to be heat only or heat/cool. The operator station includes a rugged LCD touch screen with CE.NET operating system, Modbus TCP/IP Ethernet communication, and a 1GB flash back up memory stick as standard. The building block architecture of the Control Module allows a compact, lower cost-of-entry control solution for small to large extruders. Standard control system definitions save valuable engineering time and expense. The system is preprogrammed to meet the user's requirements. The program is loaded, tested and a memory stick back up is supplied for true out-of-the-box performance. The temperature card is designed specifically for single-screw, twin-screw, co-extrusion or blown film applications. Fully automatic adaptive temperature tuning (as well as conventional tuning) is provided. Predefined screens and sequence logic greatly simplify installation and setup. Recipes, screen captures and logging functions can be stored and loaded from various memory devices. Applications that match the predefined screens and logic will not require additional programming. Includes real time clock and battery backup.

Features:

- Adaptive auto-tuning for precision pressure and temperature control

- Preconfigured screens and sequences saves time and expenses

- Differential Pressure display and alarming

- Alarm logging and historic trending for sophisticated data capture

- Ethernet communications simplify installations

- Recipe management for quick set-up and true plug-and-play operation

- Security password protection

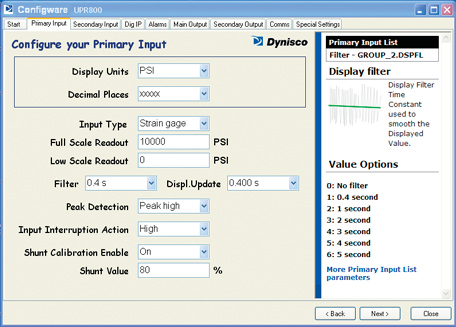

4) Configware Software Package:

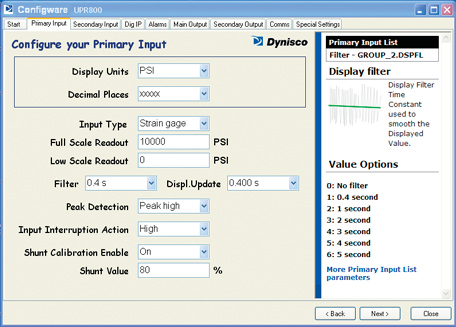

Configware is a universal software package that can be used to configure several different Dynisco panel instruments, including the: UPR800 (1/4 DIN process indicator), ATC880 (1/4 DIN process controller), TCE (Vertical 1/8 DIN temperature controller), TCS (1/16 DIN temperature controller), 1380, 1390 and 1391 (1/8 DIN pressure indicator), 1392 (1/8 DIN temperature indicator).

Install Configware on your personal computer and connect the Configurator Port Interface (CPI) via RS-232 port to the Dynisco instrument to be configured. Configware will automatically recognize the instrument model and display the appropriate configuration screens. Using the Configware screen tabs and dialog boxes, select the desired configuration parameters. Use the Help tips conveniently located at the right of screen to guide you through your selections.

With configuration parameters selected, save the settings as a backup or clone the configuration into other like models that will employ the same settings.

Features:

- Configure several different Dynisco instruments with one software package

- PC configuration saves time and effort

- Clone the configuration of one instrument to another

- Save configurations in the event an instrument needs to be re-configured

- The Configware screen is very user friendly

- A Help sidebar makes an intuitive process even easier

Dynisco offers a variety of robust instrumentation. Whether you need an indicator or a controller for pressure or temperature, Dynisco can provide you an instrument that will suit your application. Depending on your needs, the instrument can be supplied with transmitter power supply, alarms, auto-retransmission capabilities, control capabilities, digital communications, etc.

(For images, please see next pages)

For More Details Contact:

Manan Enterprise

Mr. Yogesh Desai

Tel.: +91-22-26102833

Mobile: +919819301890

E-mail: manan@bom4.vsnl.net.in

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}