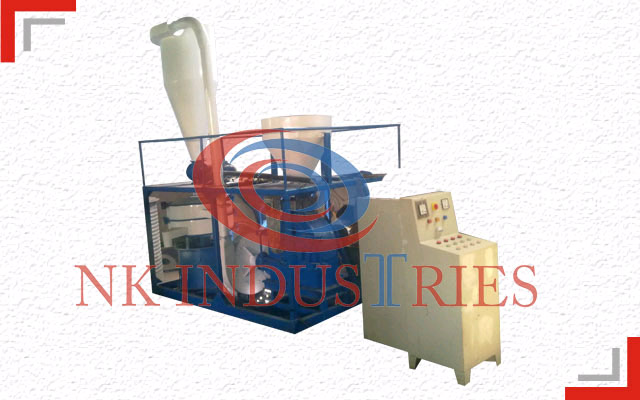

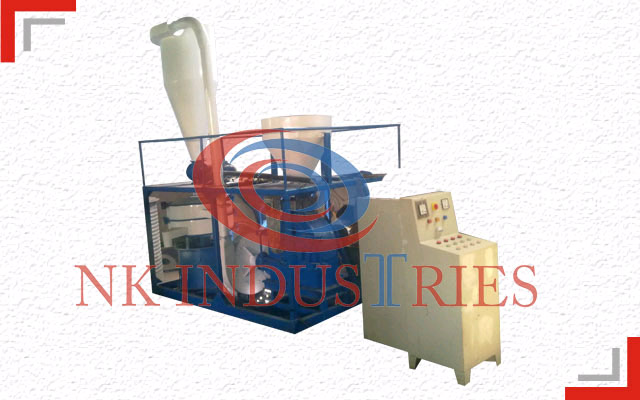

For Sale - AIE - 3355 - Pulverizer Machine

Reference Numbers

AIE - 3355Product

Pulverizer MachineManufacturer

N. K. Industries, India

Pulverizer devices are utilized in order to break materials in to small shards or even granules. Pulverizer devices may grind all sorts associated with products, such as plastic material, lightweight aluminum, rock and roll, resin, rubber wheels, as well as healthcare waste materials. Pulverizer devices arrive in many various types. NK Industries are best provider of Hammer Mills, Double Mill Pulverize machine, single mill pulverize machine. Pulverizer can be used within plastic material business with regard to Materials Pulverizing Such as PVC Recycling where possible, Rotational Molding, Compounding as well as Grasp batching.

NK Industries pulverizer machines guarantees the actual manufacturing associated with pulverized materials through plastic material granules for that production associated with top quality last items. Pulverizer may pulverize LDPE, LLDPE, HDPE as well as numerous thermoplastic supplies along with other types of pulverize with regard to various supplies.

Pulverizer offers completely automated procedures along with established series associated with procedures for example Automated granule lifter, Automated off and on feeder, Automated regulates associated with generator heat and so on. The actual Pulverizer comprises associated with top quality, maintenance-free and deploy effective elements.

NK Industries best Pulverize Machines comes with technologies like Excellent Cooling System like Housing Cooling, Mill Cooling and rotary disc cooling with quality out-put capacity from virgin materials. NK Industries Pulverizer machines work with very low maintenance & easy to use. Pulverize machine also have the special monitoring equipments which balances the machine load as well as machine safety.

NK Industries Single Mill Pulverize Machine & Double Mill Pulverize Machine has its own unique facility. As discussed here below are some more features of our product.

- Reduced energy usage along with higher result output of the production.

- Affordable cost effective manufacturing along with consistence high quality result.

- Very less maintenance & works with less man power

- Graded alloy steel made grinding disk

- Cooling supply towards Single Mill / Double Mill body including bearing disks

- Vibro feeder or Auto Servo manage material feeding system.

- Checking associated temperature with powder Heat & control dashboard.

- High quality digital display with Microprocessor components.

Model Design readily available for LLDPE with regard to Rotomoulding RECREATIONAL VEHICLE. D., WISH, PS, SILICON RUBBERIZED, DOG, CAR Tyres recycling where possible vegetation, EVA/RUBBER/PU Combined flip flops Sectors, GRASP ORDER producers.

(For picture, please see next page)

For More Details Contact:

N. K. Industries

Mr. Mahendra Panchal

Tel.: +91-79-25841423

Mobile: +919727391883

E-mail: info@nkindustries.in

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}