For Sale - AIE - 3478 - Small Range and IML 8-Series Robots

Reference Numbers

AIE - 3478Product

Small Range and IML 8-Series RobotsManufacturer

Wittmann Battenfeld India Pvt. Ltd.

Wittmann offers:

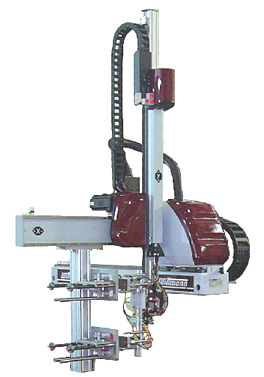

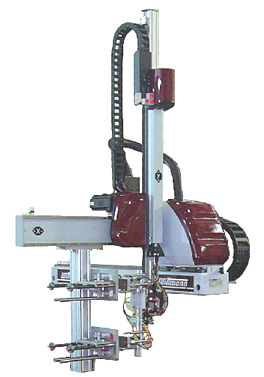

1) W801 3-Axis Servo Robot:

The smallest model in the 3-axis servo robot line designed for mounting on molding machines up to 120 tons clamping force.

- Motorized servo drives on all 3 main axes.

- Compact construction of the vertical axis and the highly integrated wrist rotation allow handling of parts with the minimum amount of mold open space.

- High performance servo drives and high grade linear rails on all axes permit high velocities and the shortest part removal times.

- Many additional features of the entire robot series are available as options including: vacuum and gripper circuits and different I/O modules for the control of complex peripheral equipment.

2) W811 3-Axis Servo Driven Robots

The optimum robot providing flexible automation for your existing and future requirements on smaller molding machines.

- High Performance Robots: All three main axes feature servo drives

- Minimum Removal Times: Fast removal of the molded part is essential for the highest productivity of the automation cell e.g. production of phone parts. The vertical arm of these robot models is a stiff but lightweight aluminum extrusion driven by a servo motor via a belt, thus reducing the movable weight.

- Option: The robot W 811 can be equipped with double arm for the flexible automation of three-plate mold applications.

Model S: Additional vertical arm (pneumatically driven) with mechanical gripper for sprues.

Model D: For stack mold automation.

All fully servo driven robots are programmed by using the graphical robot programming TeachBox R7.2.

3) W813 with Telescopic Vertical Arm:

Same basic design as W811 with 3 servo driven main axes.

- Vertical axis with telescopic stroke for low overall height

- The perfect robot for smaller molding machines in production halls with low ceiling heights

- Very compact design of telescopic arm providing small mold opening height and fast removal time

4) W717 for Use with IML Systems:

Wittmann has introduced a completely new In-Mold Labeling (IML) solution developed for the highest efficiency and at the same time lowest capital cost for the customer.

The IML system is based on the new W717 robot, suitable for molding machines in the range of 80 to 250 tons clamping force and molding cycles of 5 seconds or greater. The system allows automatic insertion of labels into one up to four cavity molds and free dropping of the finished parts after the molding process. The W717 robot comes equipped as a standard with the economical SA7 robot control system allowing any arbitrary teach program sequence and easy setup of the system.

(For images, please see next pages)

For More Details Contact:

Wittmann Battenfeld India Pvt. Ltd.

Mr. Nandakumar T.

Tel.: +91-44-42077009

Mobile: +919884909911

E-mail: nanda.kumar@wittmann-group.com

Web: http://www.wittmann-group.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}