For Sale - AIE - 3519 - Dosimax - Volumetric Dosing Systems

Reference Numbers

AIE - 3519Product

Dosimax - Volumetric Dosing SystemsManufacturer

Wittmann Battenfeld India Pvt. Ltd.

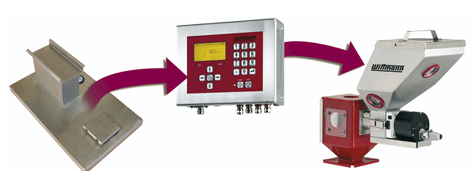

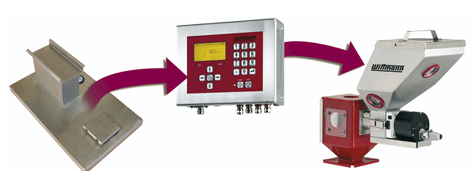

Wittmann Dosimax - Volumetric Dosing Systems:

1) Dosimax MC Basic:

- Digital Revolution Setting: Revolutions from 0 to 200 rpm within 0.1 rpm steps

- Digital Time Setting: Settings from 0 to 999 sec. within 0.1 sec. steps

- Timer mode for injection molding applications

- Keyboard Lock: 1 Level

- 4-Digit, 7 segments LED on front display

- Man/Machine Interface via Keyboard Foil

2) Dosimax MC 12 and MC 18

a) Dosimax MC 12:

- Digital revolution setting from 0 to 200 rpm within 0.1 rpm steps

- Digital time setting from 0 to 999 sec. within 0.1 sec. steps

- Timer and relay mode for injection molding applications

- Keyboard lock: 1 level

- 4-digit, 7 segments LED on front display

- Man/machine interface via keypad foil

- Neckpiece with cleaning door

- Quick material discharge slide gate

b) Dosimax MC 18

- Digital revolution setting from 0 to 200 rpm within 0.1 rpm steps

- Digital time setting from 0 to 999 sec. within 0.1 sec. steps

- Tacho synchronization for extrusion applications

- Constant dispensing through automatic adjustment of rotation speed

- Integrated conveying control

- Keyboard lock: 1 level

- 4-digit, 7 segments LED on front display

- Man/machine interface via keypad foil

- Neckpiece with cleaning door

- Quick material discharge slide gate

3) Dosimax Semi-Gravimetric Dosing System

a) Dosimax MC 30:

- Set % setting for injection molding and extrusion

- Timer and relay mode for injection molding applications

- Tacho synchronization for extrusion applications

- Keyboard lock: 4 levels

- Integrated conveying control

- Data memory for production and machine configuration

- Full graphic LCD display with backlights

- Neckpiece with cleaning door

- Quick material discharge side gate

b) Calibrator for MC 30:

- Place the dosing unit on the calibrator and enter the production values.

- The calibration result will be automatically saved.

- Place the dosing unit on the neckpiece, the volumetric feeding starts with the exact settings.

4) Dosimax - Gravimetric Dosing Systems

a) Dosimax MC Balance:

- Accurate dosing results because of loss-in-weight measurements

- User-friendly and easy operation because of quick calibration

- Set % setting for injection molding and extrusion

- Timer and relay mode for injection molding applications

- Tacho synchronization for extrusion applications

- Keyboard lock: 4 levels

- Integrated conveying control

- Data memory for production and machine configuration

- Full graphic LCD display with backlight

- Man/machine interface via keypad foil

- User programmable alarm levels

b) Dosimax MC Twin:

- Accurate dosing results because of loss-in-weight measurements or auto calibration

- No calibration needed after colour change

- Set % setting for injection moulding and extrusion

- Timer and relay mode for injection moulding applications

- Tacho synchronization for extrusion applications

- Keyboard lock: 4 levels

- Integrated conveying control

- Data memory for production and machine configuration

- Full graphic LCD display with backlight

- Man/machine interface via keypad foil

(For images, please see next pages)

For More Details Contact:

Wittmann Battenfeld India Pvt. Ltd.

Mr. Nandakumar T.

Tel.: +91-44-42077009

Mobile: +919884909911

E-mail: nanda.kumar@wittmann-group.com

Web: http://www.wittmann-group.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}