For Sale - AIE - 3524 - SUMO Screenless Granulators

Reference Numbers

AIE - 3524Product

SUMO Screenless GranulatorsManufacturer

Wittmann Battenfeld India Pvt. Ltd.

Wittmann SUMO Screenless Granulators:

1) Series SUMO Minor:

For Small and Medium Sized Sprues and Parts

- 2 models available

- Compact footprint

- Low feed height

- Power up to 1.1 kW (Minor 1) and 1.5 kW (Minor 2) by gear motor directly on the shaft

- Polycarbonate hopper

Option:

Soundproofed sheet metal hopper (stainless steel inside)

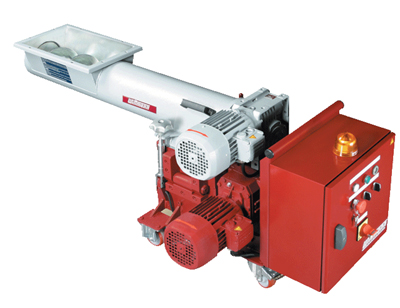

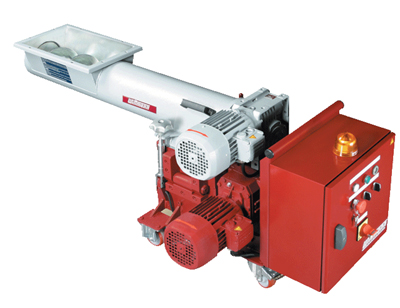

2) Series SUMO Minor with Auger:

For receiving sprues directly under the IMM

This granulator is equipped with an auger for placement directly under the injection moulding machine. Design based on the cutting chamber dimensions of the Minor 1.

Options:

- Different lengths of auger opening: 600 x 230 mm

- Metal detection system "Metalstop" (patented)

- Double ARS (automatic reversing system) on auger and rotor

- High level detector

- Hopper on auger trough for robot feeding

- Reversible execution: gear motors and auger screw opening on the other side

- Auger trough height of 543 mm and bin with 360° swivel outlet

3) SUMO Junior 2 Compact

The SUMO Junior 2 C screenless granulator fits perfectly into the product portfolio between the SUMO Minor 2 and Junior 2 granulators. Because of the reduced floor space requirements (approximately 40 percent less than the Junior 2) this granulator is ideally suited for use beside the molding machine. Like the Junior 2, this model is also designed for the recycling of bigger sprues and hard or filled plastic parts.

4) SUMO Junior 1, 2 & 3

For Medium Sized Sprues and Parts

- 3 models available

- Gear motor with coupling is easy to disconnect to facilitate maintenance

- Power: 1.5 or 2.2 KW by gear motor and coupling

- Soundproofed sheet metal hopper (stainless steel inside)

Option: Polycarbonate hopper

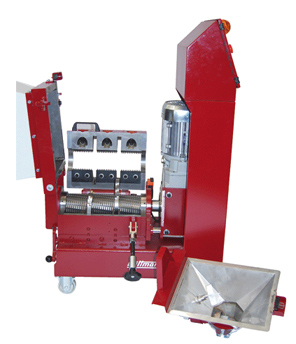

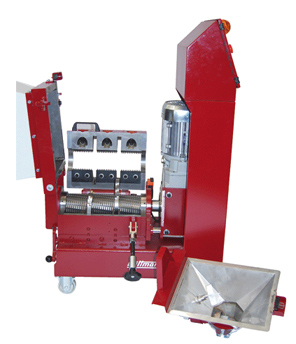

5) Series SUMO Junior Double

For Large Sprues and Parts:

JD (Junior Double) granulators are fitted with a double rotor which allows for processing of bulky sprues and parts as well as for higher throughput rate, e.g. large automotive parts: bumpers, dashboards, etc.

The three models JD43, JD63 and JD83 use interchangeable cutting components:

Gas-spring assisted hopper opening

Vacuum bin with 360 Degree swivel adapter mounted on casters

Option:

The three models JD43, JD63 and JD83 have a third shaft mounted in hopper for feeding parts into the cutting chamber.

(For images, please see next pages)

For More Details Contact:

Wittmann Battenfeld India Pvt. Ltd.

Mr. Nandakumar T.

Tel.: +91-44-42077009

Mobile: +919884909911

E-mail: nanda.kumar@wittmann-group.com

Web: http://www.wittmann-group.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}