For Sale - AIE - 3547 - High Speed Heater-Cooler Mixers

Reference Numbers

AIE - 3547Product

High Speed Heater-Cooler MixersManufacturer

Shree Radhekrishna Extrusions Pvt. Ltd., India

The concept of the Radhekrishna Heater cooler mixers as a fluidizing mixer not only meets the requirements of the excellency of design with gentle treatment of the material, but also permits easy cleaning, and the maintenance of cleanliness. Radhekrishna mixer offers the best solution to all processors need for PVC dry blend, both rigid and plasticized.

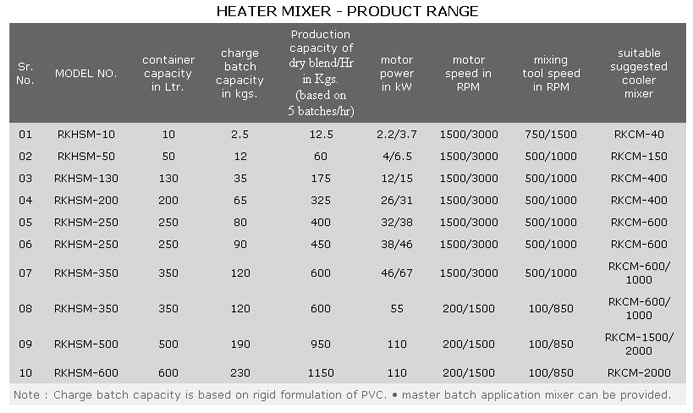

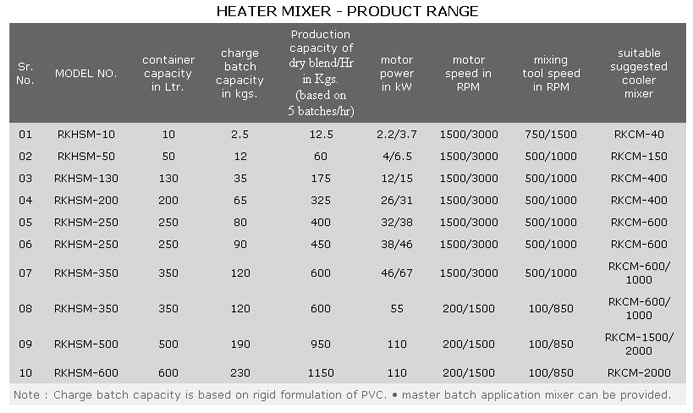

High Speed Heater Mixers:

In mixers, the heat generated due to friction is utilized to mixing materials & hence known as "Heater Mixer". Where the mixing tool is mixed rapidly and uniformly to give a homogeneous compounded products. High speed heater mixers are used to mix solid, liquid and pasty components.

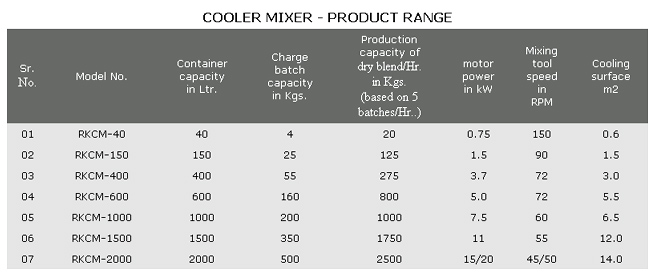

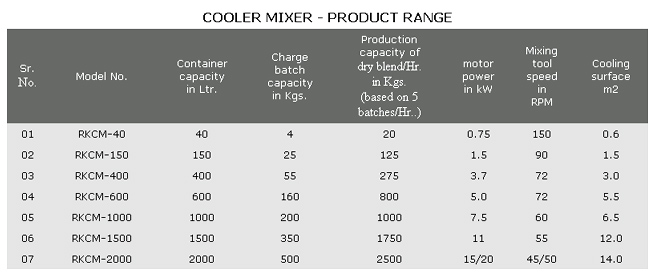

Cooler Mixers:

The mixer is placed in line with "Heater Mixer" and used to cool down the not mix produced in heater mixer, at minimum temperature for safe storage. The cooling ring contributes to the efficiency of the cooler mixer. These give in combination with the cooled vessel wall a large heat exchange surface. Cleaning the cooling mixer is simple because the lid can be completely swung aside and the inside is easily accessible.

Heater-Cooler Mixer Combinations:

The combination of heater-cooler mixer designed as a single robust and economy unit. Heating and cooling mixer combination consist of a heating mixer followed by a cooling mixer. They are mounted on a common base that consists of a distortion free construction. Large and easily removable covering panels ensure easy access to the interior part of the base.

Range of Application

- PVC preparations including E-PVC

- Mixing ABS powder with filler and auxiliary components

- Master batches application

- Preparation of rubber mixtures

- Preparation of different batches with stabilizers,

- Lubricants or pigment on plastic powder basis

- Foodstuff and medical powder application

- Cosmetic and ceramic product compound

- Mineral application

Salient Features of AC variable frequency drive:

- Smooth motion programmable, hence no jerks on drive on drive system components and electrical instruments, which increases life of machine.

- Variable drive system is very compact and maintenance less with fully electric protection over short circuit.

- A complete electrical system will be less loaded at the time of starting operation, hence low starting torque.

- Easily programmable and pre selection for automatic operation.

- Tool speed can be easily adjusted as per the formulation requirement.

- Tool speed is digitally displaying on panel screen.

Salient Features of Heater Cooler Mixer:

1) Stainless steel mixing vessel

- Corrosion resistance and abrasion resistance

2) Vessel and discharge plate high gloss polished on the inside; discharge plate matches bottom dish

- No deposits, crusts or pockets of colour

- Rapid and complete discharge of the mixed material

- Easy and perfect cleaning

3) Mixing tools self-purging, adjustable in height, specific to the material being mixed, simple design

- Made from stainless steel, thoroughly hardened and buffed

- Homogeneous mixtures

- Optimum adaptability to each type of mixing charge and size of charge

- Easy, rapid removal and refitting

- Optimum dispersion and distribution of the components of the mixture

- 5 batches per hour for hot mixing

4) Pneuma Seal Housing Design Flow Deflector

- Avoids material infiltration to bearings

- Optimum setting of mixing process

- Rapid homogenization

5) Temperature Sensor in Thermo well socket

- Measures temperature of material accurately

6) Twin jacket for heating or cooling

- Adaptability to type of mixing charge

7) Twin jacket for cooling, with forced circulation of cooling water (cooler vessel)

- Optimum dimensions of cooling surface

- Intensive cooling of the mixed material

- Cooling in step with heated mixer

8) Cooling ring (cooler vessel)

- Increase in cooling surface

- Reduction in cooling time through forced circulation of mixing charge

9) Optional chopper, with separate drive (cooler vessel)

- Agglomerate size can be chosen

- Avoids lump formation

- Homogenization of the mixing charge

- Optimizations and shortening of the mixing process

10) Dual speed motor

- Higher batch production and higher tool speed

- Variable tool speed and low power consumption

11) Freely programmable controls

- Optimum adaptability to process technology requirement

- Constant high quality of the mixed material

12) A matching cooler mixer for every heater mixer

- Versatile in use

- Mutually balanced heating and cooling capacity

- Adapted to the process technology requirements, type of mixing charge, batch size and batch number

13) Mixer combination can be supplied as individual machines

- Transportation and fitting are simple

- Customer saves costs by constructive platform in-house

(For more details and images, please see next pages)

For More Details Contact:

Shree Radhekrishna Extrusions Pvt. Ltd.

Mr. R. B. Patel, Mr. Tejas Patel

Tel.: +91-79- 25842509, 25841785

Mobile: +919824073240 (Mr. R. B. Patel) / +919824410997 (Mr. Tejas Patel)

E-mail: srke_co@yahoo.co.in, mail@radhekrishnaexports.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}