For Sale - AIE - 4039 - Hopper Dryers, Hopper Loaders and Temperature Controllers

Reference Numbers

AIE - 4039Product

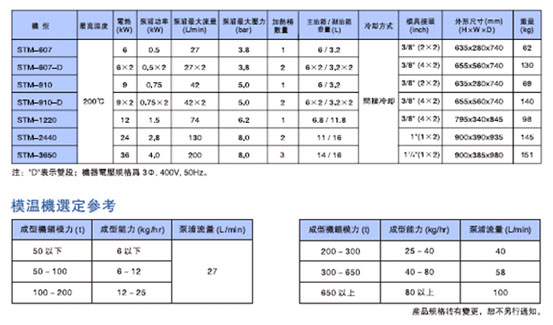

Hopper Dryers, Hopper Loaders and Temperature ControllersManufacturer

Associated Technocrats Pvt. Ltd., India

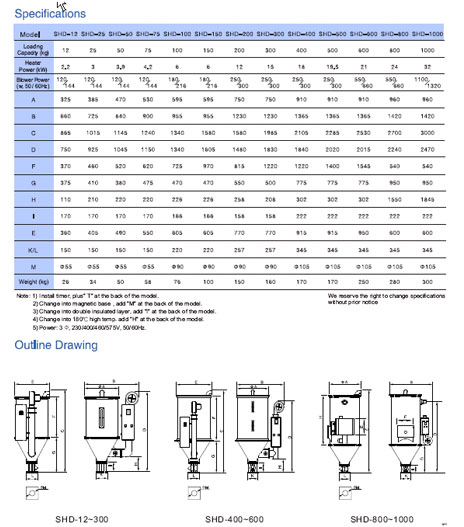

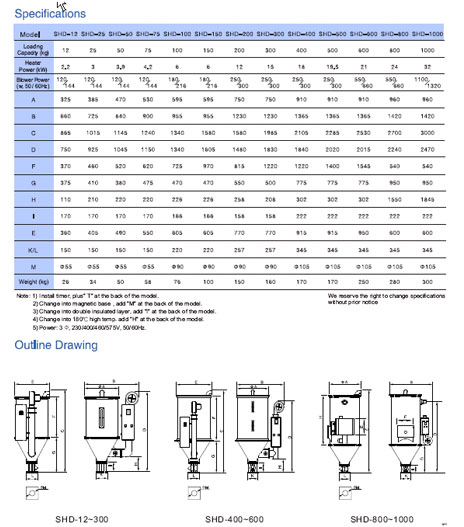

Model: SHD series "Econo" hopper dryers

We offer an effective and low-cost method for plastic material drying. Hot air is used to dry wet materials due to moisture absorption during packaging, transportation, and recycling cycles. They can be directly mounted on the moulding machine for quick drying and space saving. For this series, hot air blows evenly from bottom to the top (both SHD-800 and SHD-1000 have down-blowing air pipe and accessible door for easy material clearance) of the hopper with capacity ranging from 12kg to 1000kg. All models can be supplied with optional 24 hours auto start/stop timer

Features:

- Adopt hot air diffuser to gain an even hot air flow to improve drying efficiency.

- Unique hot air inlet elbow design can prevent dust piling up at bottom of the pipe heaters so to avoid burning.

- All material contact surfaces are made of stainless steel to eliminate material contamination.

- Separable hopper base provides easy access to hopper tank for the convenience of material changing and cleaning.

- Proportional deviation indicative temperature controller for accurate temperature control

- Overheat protectors to prevent accidents by human error or mechanical faults.

- Overheat indicating light, motor contactor and overload relay are equipped standard.

- Quick cooling blower and outfitted power switch.

- Preheat timer and double insulated hopper are available as options.

- More optional accessories: dried-material suction box, hopper magnet, magnetic base, hot air recycler, blower inlet filter, exhausted air filter, cyclone dust separator and 'N' type floor stand

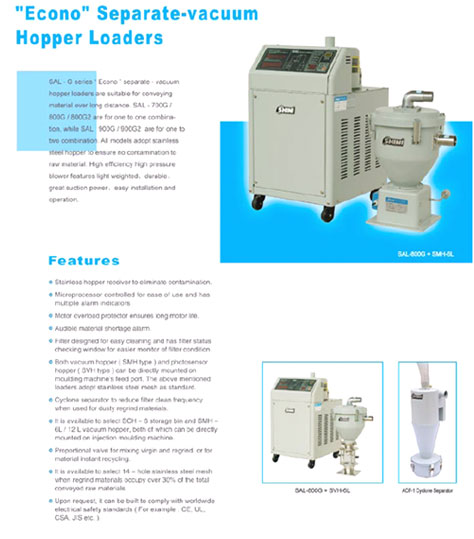

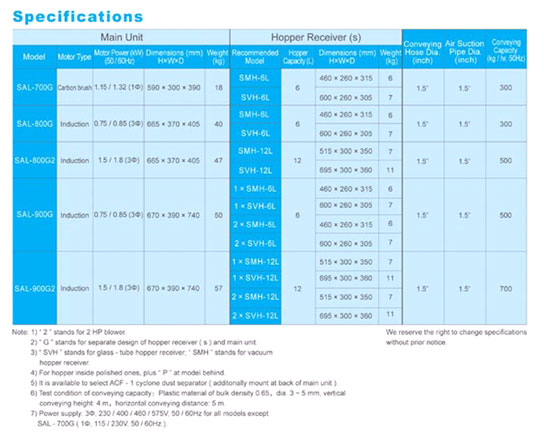

(For Hopper Loaders and Temperature Controllers, please see next pages)

For More Details Contact:

Associated Technocrats Pvt. Ltd.

Mr. Sanjeev Verma

Mobile: 09818912000

Email: atpl@atplonline.com, info@atplonline.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}