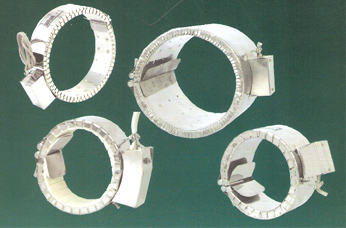

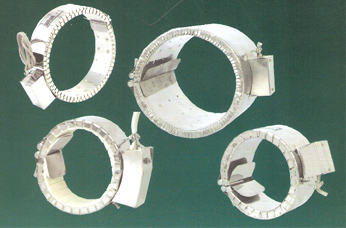

For Sale - SRP - 3118 - Ceramic Band Heaters

Reference Numbers

SRP - 3118Product

Ceramic Band HeatersManufacturer

Ace Heat Tech, India

Ceramic band heater consists of helically wound resistance coil which is of Nickel Chrome wire.

This coil is passed through holes in specially designed ceramic bricks in such a way that coil is evenly stretched and flexible ceramic heating mat gets formed.

This mat is covered with insulating fiber wool for eliminating heat emission on outer side of the band.

Serrated cylindrical stainless steel housing is used to enclose the heating mat along with insulating wool.

This makes the heater very flexible and very easy to install.

The transmission of heat is by conduction and radiation.

The maximum watt density is 7 watt per square centimeter and maximum temperature is 760 Degree C.

These are also available with blower. The heaters are without insulating materials and blowers are installed on the outer side of the heater.

The ceramic band heaters can be fitted with termination of customer's choice.

Design Feature:

- Energy saving

- Minimal heat loss

- Built-in thermal insulation.

- Uniform temperature

- Maximum flexibility for easy installation.

- Longer heater life.

Electrical rating & construction:

- Maximum voltages: 480 V AC

- Maximum current: 25 Amp

- Maximum temperature: 760 Degree C

- Resistance tolerance: +10 %, - 5%

- Maximum watt density: 7 W/cm2

- Wattage tolerance: +5%, -10%

- Sheath material: Outer SS, inner MS or as per requirement

- Insulation material: 1/4" thick ceramic fiber blanket.

- Overall thickness: 10 mm or 5/8", min. width 1"

- Minimum diameter: 2"

- Maximum diameter: 44"

Applications:

- Wire and cable industry

- Heating barrels of plastic injection moulding machines and extruders.

- Die and die holders heating of plastic extruders and blow moulding machines.

- Heat treating of pipes.

Any application requiring heat applied to a cylindrical surface.

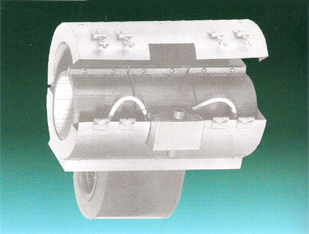

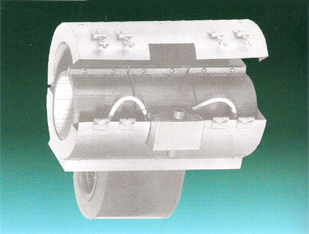

Air Cooled Blower Heaters:

Ceramic band heater is covered with a perforated SS body and blower is designed for use on plastic extrusion machine. The blower will engage into coating process, if the pre determined temperature is exceeding.

(For images, please see next pages)

For More Details Contact:

Ace Heat Tech, India

Mr. Dinesh Kotian

aceheattech@vsnl.net

Tel.: 022-2580 6001/2/3

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}