For Sale - SRP - 3277 - Wire Mesh and Wire Cloth

Reference Numbers

SRP - 3277Product

Wire Mesh and Wire ClothManufacturer

Indian

Woven wire cloth basically consists of stainless steel wires crossing at right angles to form uniform square openings also known as aperture. This is done by weaving process of weaving horizontal wires (also known as weft wire) into longitudinal wires (also known as warp wire). During the weaving process both the wires criss cross and get crimped in the weaving process. By modifying weaving patterns and wires one can obtain square rectangular and triangular openings.

Application of S. S. Wire mesh:

Stainless steel wire mesh is widely used for filtration/ separation in industries like chemical, metallic powders, minerals, dyes and pigments, fertilizers, ceramic industry, paints, filter elements, inks, food process industry.

Standard range of Wire mesh

Based on the ASTM Standards, we produce a comprehensive range of wire mesh meeting the most exacting requirements of the sieving industry. Our product grades are available in the indicated materials either from stock or at short notice from current production. Every user of woven wire cloth has thus possibility of covering his requirements at short notice, in top quality, at reasonable prices and in accordance with the latest international standards. Manufacturing range from 4 mesh to 1500 mesh in stainless steel grades like 304 and 316 as per customer specifications with different types of weaving wire cloth.

Wire cloth width:

1000 mm (39") and 1220 mm (48") are readily available, other widths up to 2000 mm (2 meter) are also carried in stock or can be custom woven.

Type of Wire Mesh:

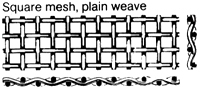

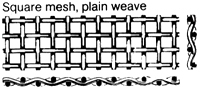

1) Square mesh - Plain weave:

Wire cloth with square mesh plain weave give maximum possible accuracy of aperture and is consequently the most widely used type of weave. Full details are provided in the table below. In addition, we custom weave the following size of width: 1mt. / 1.22mt. / 1.5 mt. / 2.0 mt.

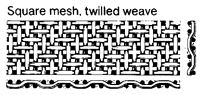

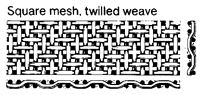

2) Square mesh - Twilled weave:

Wire cloth with square mesh having a slight diagonal displacement mostly fine wire cloth with aperture under 63 microns and specifications woven with especially thick wires.

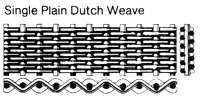

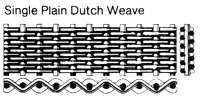

3) Single Plain - Dutch Weave:

The weft wires are plain-woven to lie as Close as possible against each other.

Qualities:

High degree of filtration, high flow rate, moderate pressure loss. SPW has an uneven surface on both sides.

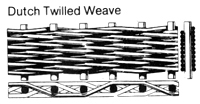

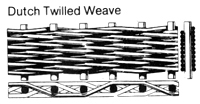

4) Dutch Twilled Weave:

Also called light-tight weave. The weft wires are twill woven to lie as close as possible.

Qualities:

Maximum degree of accuracy in filtration, low flow rate, high-pressure loss. DTW is smooth surface on both sides.

(For images, please see next pages)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}