For Sale - SRP - 3661 - Electrostatic Oil Cleaner

Reference Numbers

SRP - 3661Product

Electrostatic Oil CleanerManufacturer

Pune Energy Control Devices Pvt Ltd., India

Advantages of Electrostatic Oil Cleaner:

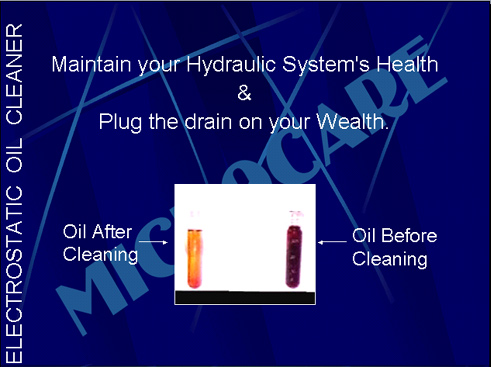

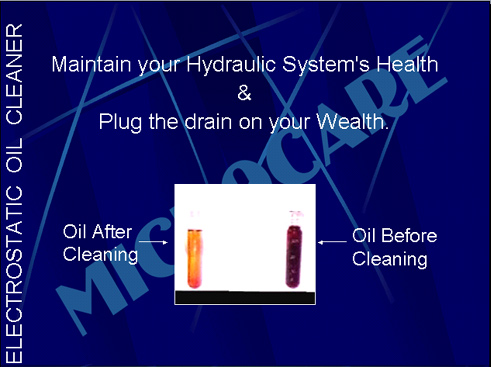

- Reduction in oil replacement cost.

- Reduction in machine downtime.

- Improves life of the hydraulic system components.

- Ensures un-interrupted manufacturing process.

- Lower rejection rate.

Types of fluids cleaned

- Hydraulic oil

- Turbine oil

- Bearing lubrication oil

- Straight cutting oil

- Any other non-conductive liquid

Limitations on use of EOC

- Fluids with viscosity above 200 CST

- Operating temperature above 600 Degree C

- Moisture content over 500 PPM

- Oils with detergent additives

User Industries:

- Plastic injection moulding

- Extruding and pressure die-casting

- Hydraulic presses

- General hydraulics / servo valves

- Turbine control and bearings

- Hot & cold rolling mills

- Precision machine tools

- Earth moving, construction & mining equipments

- Cement plants

- Power plants

Salient features:

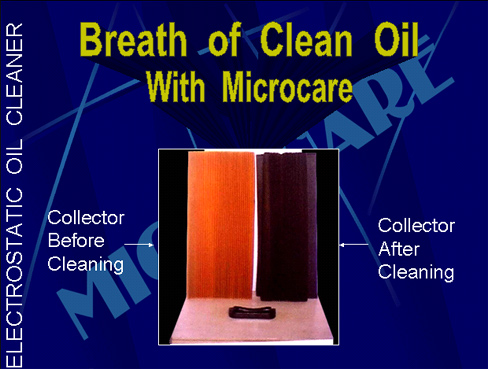

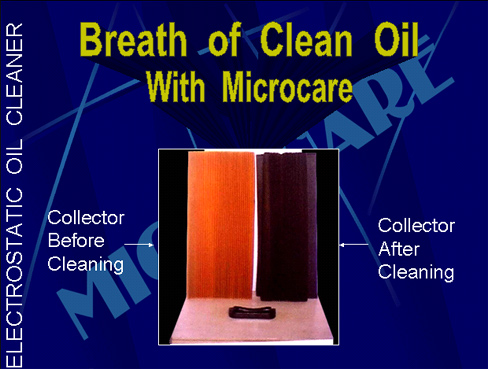

- Removes all suspended contaminants down to 1 micron size.

- Low energy consumption and operating cost.

- Pollution free process.

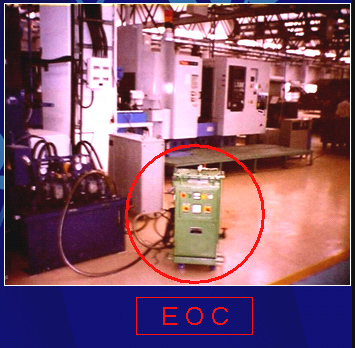

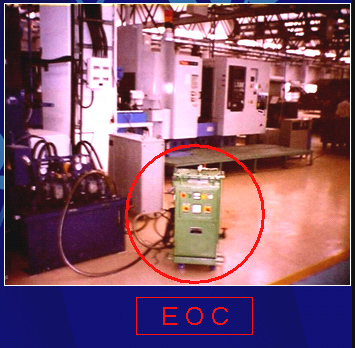

- Trolley mounted portable unit.

- Maintains original properties of liquid being cleaned.

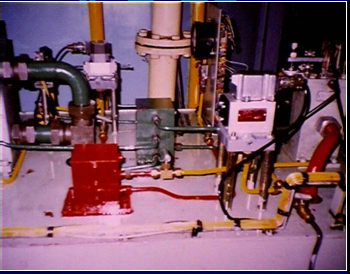

- Unattended operations after initial start up.

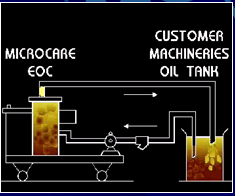

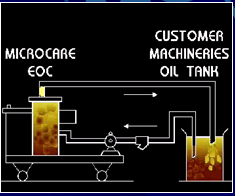

Principle of operation:

Microcare is an electrostatic super cleaning equipment involving removal of suspended contaminants in fluids / oils and collecting them on an enormously spread surface of die-electric media.

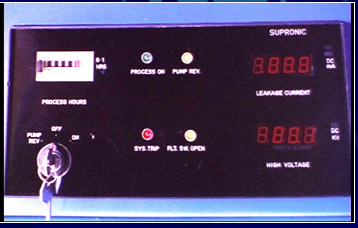

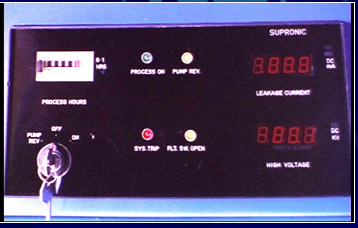

Highlights of Electronic Control Panel

- Total operation control with one key switch.

- Continuous monitoring of high voltage and load current.

- Reduced electrical components and wiring.

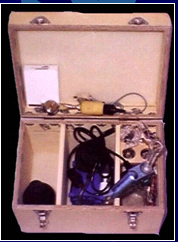

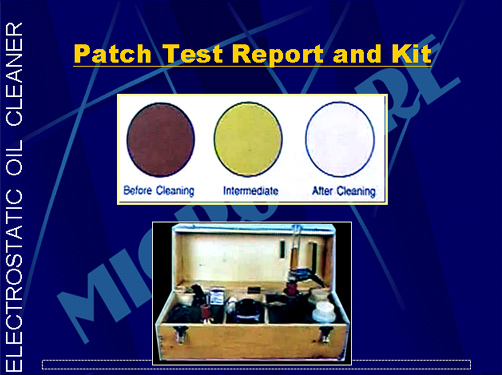

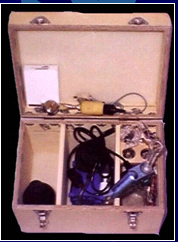

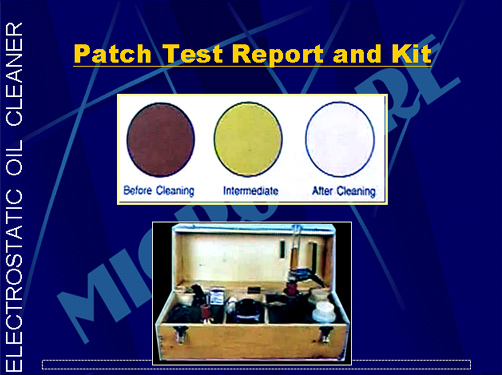

Contamination Checking Kit:

The results of oil cleaning are checked using this kit supplied with the machine. This is a comparative test based on the patch test carried out on 0.8 micron membrane filter for dirty and clean oil.

Components of the kit:

- Graduated test tube

- Graduated glass cylinder

- Membrane filter

- Membrane holder

- Rubber grommet

- Titration flask

- Clamp

- Vacuum pump

- Rinsing bottle

- Wooden box

- Picker

- Moisture testing gun

Some of our valued customers who are Microcare users:

Plastic:

- National Plastics Ltd.

- Anchor Kenwood Electricals Ltd.

- Cello Group of Companies

- Exotech Plastics Ltd.

- Gaurav Agroplast Ltd.

- Today's Writing Products Ltd.

Automotive:

- Bajaj Auto Ltd.

- Mahindra & Mahindra Ltd.

- Tata Engineering & Locomotive Co. Ltd.

Power Plants:

- Triveni Engineering & Industries Ltd.

- Tata Electric Company Ltd.

Cement manufacturing:

- Vasavadatta Cements Ltd.

Steel manufacturing:

- Bokaro Steel Plant

- Durgapur Steel Plant

- Jindal Iron & Steels Ltd.

Non-Ferrous metal manufacturing:

- Indian Aluminium Ltd.

- Swil Ltd.

Earth Moving Equipments:

- Sanghvi Movers Ltd.

Engineering:

- Kalyani Brakes Ltd.

- Bharat Heavy Electricals Ltd.

- Ingersoll Rand Ltd.

(For more details and images, please see next pages)

For More Details Contact:

Pune Energy Control Devices Pvt Ltd.

Mr. Milind Agnihotri

Tel.: +91-20-25386093

Mobile: +91-9921050061

E-mail: pecd@vsnl.net

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}