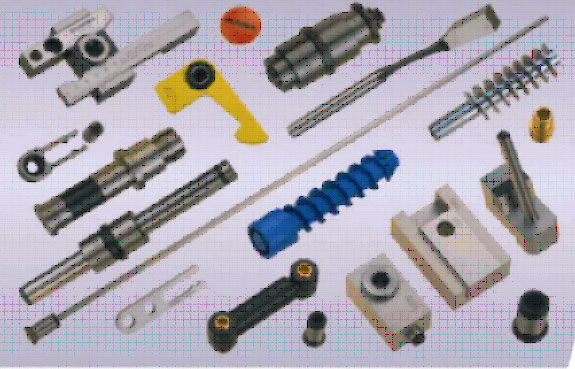

For Sale - M - 1382 - Innovative Mould Parts

Reference Numbers

M - 1382Product

Innovative Mould Parts

CUMSA has always had a very clear objective of maintaining the latest technological improvements through innovation and constant research & development. CUMSA standard parts are completely interchangeable, manufactured with the highest tolerances and precision, giving the customer a series of competitive advantages:

- Quick Calculation of Costs and Planning.

- Cost reduction.

- Time savings in mold manufacturing.

- Mold size reduction.

- Quick part adjustment with mold in machine.

- Reduction of machine downtime.

- Quick part replacement.

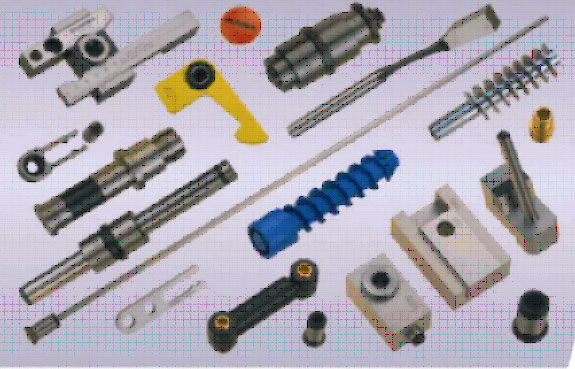

- CUMSA recently introduced NEW mould components such as

A) Compact coring unit

- This unit uses the open and close movement of the mould to make lateral holes in wall section of plastic parts.

Easy to assemble and remove from the mould.

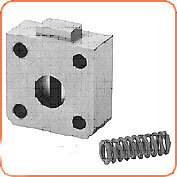

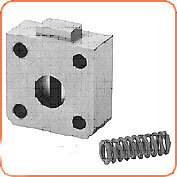

B) Shock absorber:

- Used to minimize the vibrations caused by the ejector plates returning to position.

- The main advantage is the increase in the life of parts within the ejector frame through the reduction of damage and wear.

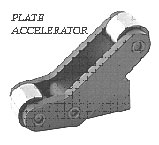

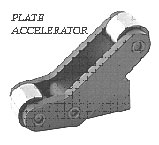

C) Plate Accelerator:

- This item allows increased movement of a second ejector plate within a normal ejector stroke.

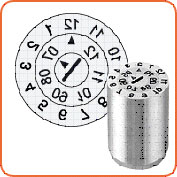

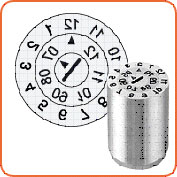

D) Double date stamp

- Allows two different indications on the plastic part without the need for 2 date stamps, reducing costs and space required. In the standard version (12 months + 6 years), it saves to periodically change the central insert during 6 consecutive years. The same height is always maintained between all the rings.

E) Vertical lifter block:

- The main characteristics of this item are its perpendicular movement with respect to the ejector plates and the ease of adjustment.

F) Sequential marker:

- Each injected part is sequentially marked with its own number, through the action of the ejector plate movement.

G) Mini double core

- This part has the same function as the ‘Double core’ (ED) but for smaller undercuts. easily installed by only having to drill holes in the tool. easy height adjustment allowing for correction of small machining errors.

H) Mini core:

- This part is the evolution of the “Sprung Core” (PP) and the “Keyed Sprung Core” (PL) for small undercuts. thanks to the bushing, this unit is quick and easy to install.

I) Flexible Core:

- This core allows undercuts to be released in compact areas (only 4mm. thickness). Include a simple system for adjustment. a balinit C® coating ensures smooth movement and reduced wear. A new feature to this product is that it ejects first then releases the undercut.

J) Cable retainer:

- Keep cables neat & tidy in their channel. the magnets inside the part mean there is no need to drill & tap extra holes or use screws.

(For images, please see next pages)

For details contact:

Madhu Machines & Systems Pvt Ltd, Vadodara

Mr. Sabu Philip

Phone no:+91 265 2321104 / 2353886

Email Id: machinery@madhu-group.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}