For Sale - M - 1383 - BOLEXP-Guidance System

Reference Numbers

M - 1383Product

BOLEXP-Guidance System

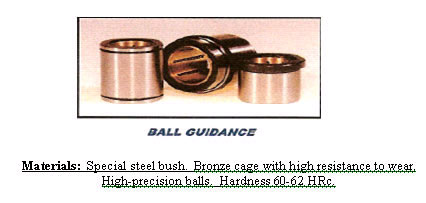

BOLEXP Ball Guidance is a high-precision rolling system with very reduced travel resistance. It is advisable for rectilinear guides where wide travels, tiny friction, high-precision guidance and positioning, together with reduced wear and long durability are required.

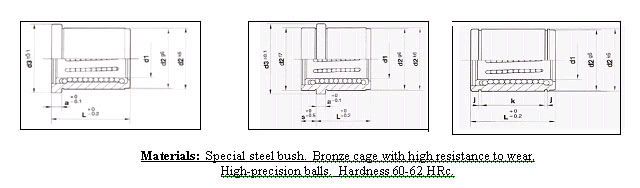

Ball Guide Bush:

BOLEXP Ball Guidance Bushes are made up of an outer casing of steel for rolling, hardened and ground, which holds fixed inside a high-resistance bronze cage for guiding the balls running along the cage. The translation system consists of several rows of precision balls circulating endlessly.

The great novelty of BOLEXP ball guidance bushes is that balls do not run aligned, with the translation motion, but at a slight angle, thus enlarging the contact area with the shaft and enabling greater load capacity. This patent system represents an utter innovation in the linear guidance market. An all-metal structure makes bushes extremely resistant to high temperatures. BOLEXP bushes are supplied in a variety of three outer forms, all of them equipped with the same inside structure.

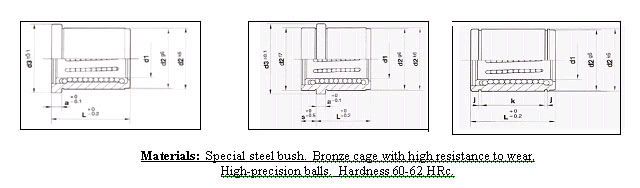

1. Bush with an outer cylindrical body and flange at the end for fixing it.

2. Bush with two outer cylindrical bodies and a center flange for fixing it between two plates.

3. Bush with an all-cylindrical outer body and two ferrules at the ends for fixing it with security spring rings.

- Guide Column:

BOLEXP guide column is made of steel 1.5732 with surface hardening, obtaining a hardness of 62-64 RHc, and a depth from 1.00 to 1.20 mm, leaving the shaft core soft so that it can absorb the bending it might be required to. In guide manufacturing, some features are considered to be essential, including the quality of steel, surface hardness and precision and quality of the finish.

- Travel Accuracy:

Travel accuracy with a guidance system using shafts with BOLEXP ball linear rolling depends on several factors, such as the positioning precision of bushes or shafts, quality of shafts, free length between shaft supports and length of the bush in relation to the area to be slid. These influences depend basically on the type of application and the load to be supported.

On the whole, the required travel accuracy is ensured by the features and design of the assembly, as well as by the precise manufacture of adjacent pieces.

Fixing the shaft at its two ends is recommended, particularly in the case of high loads, whenever the project allows it.

- Lubrication:

In order to ensure long durability for BOLEXP ball bushes, proper lubrication and maintenance are a must. The channels that the balls run along must be free from any interfering particles. Moreover, it is recommended to use oil lubrication so as to ensure proper lubrication for the whole rolling items and, if necessary, to remove all impurities.

BOLEXP suggests the use of CLP oils according to DIN51524, within the range of viscosity from ISO VG 64 to 100. Although grease can also be used for lubrication, this is not highly recommended as it fixes dirt particles much more easily.

BOLEXP ball bushes are supplied oiled for its conservation and must be lubricated when necessary. The conservancy fluid is compatible and can be mixed with mineral-based lubricants, making it unnecessary to wash bushes before assembling them

- Shaft Execution:

Shafts for BOLEXP ball bushes are hardened and ground. The ends require a tapering so that rolling cannot be damaged during the assembling. In order to fully benefit from high travel accuracy and load capacity of BOLEXP ball bushes, the shafts around which bushes slid must exhibit the best quality and properly hard layer.

Assembling And Fixing:

- BOLEXP ball bushes can be mounted either in hole with tolerance H7 or in such a way that they can be manually slid into their cartridge. Never hit them with hammers or any other impacting tool. Otherwise, the bush structure could be damaged.

- It is recommended to mount at least two units in parallel disposal so as to avoid possible rotation motions in the traveling of items. Bush length is also suggested to be at least twice its diameter in order to minimize the rotation motion of balls, whenever this is possible.

- Rotation motions are not advised in this type of bushes, whose function is that of translation.

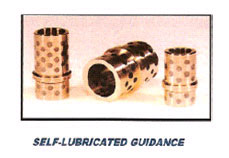

Self Lubricated Guidance:

- BOLEXP self-lubricated guidance is a travel system which adds-in solid lubricant for its operating, needing little maintenance and exhibiting high resistance in elevated-temperature operating conditions and drastic seizing reduction.

- The development of self-lubricated guidance systems arises from the need to solve the existing problems involved in lubrication. - These are due either to the difficulty of access or to be convenience of continuous and permanent lubrication, which oils fail to ensure.

- Implementing these systems results in a significant reduction in seizing problems and maintenance cots, as well as in gas emission caused by oil heating. This permits to operate at high temperatures that in some cases it reaches 400 Degree C.

- The presence of aluminum in bronze reduces the attack of atmospheric agents and warm gases, whilst exhibiting great stability against distilled water, saline water, seawater or acid well water. Bleaches, except for ammonia, are harmless to it. Moreover, a protection layer produced by the material itself acts very favorably against the corrosive effect of sulphur and oxidizing gases.

- Graphite insertions, acting as a solid lubricant, allows keeping an excellent level of lubrication for plates or bushes through all their lifetime, ready for use at any time. Through use, the bronze structure wear causes graphite insertions wear. The graphite dust resulting from this slight wear will be the responsible for lubricating the whole of the contact area.

- The graphite used is a material with an extremely low chemical-inertia level, not interacting with most elements in nature under normal conditions. This ensures regular behavior through the piece lifetime without unexpected contingency.

- BOLEXP item construction exhibits a graphite distribution over the guide surface of about 25-35% of the total, thus guaranteeing proper lubrication of the tool to construct. In addition, the graphite insertions used are relatively small, in comparison with other manufacturers, in order to minimize the impact on bronze bush consistency and maximize the dispersal of solid lubricant.

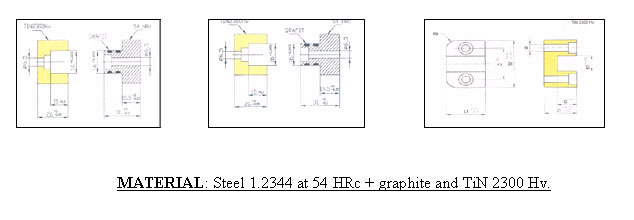

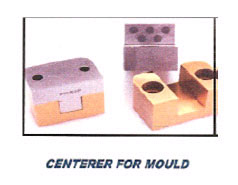

Mould Centrers:

- The centerer for moulds guarantees the appropriate alignment for the main plates in the mould. The system of fixing to plate allows to apply machinery to plates in only one operation.

- It includes graphite components for self-lubricating pieces and a TiN treatment for reducing seizing.

- The complete range of BOLEXP centerers include Graphite insertions in order to self lubricate its working in one of the pieces, the other one being coated with a TiN treatment at 2300 Hv for reducing seizing.

- Slide centerers make it possible to guarantee the appropriate alignment for the main plates in the mould.

- The fact of making the allocations in the mould bearer axis allows us to ensure the zero point of the whole structure.

- The flat centerer keeps the axis invariable where it is located as well as absorbs the +B27 longitudinal dilatations of that axis.

- The system of fixing to plate of our centrers allows to make all the mechanization of plates, figure allocations and centering system in a single operation, which guarantees a greater precision of execution

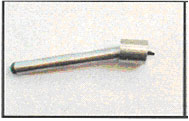

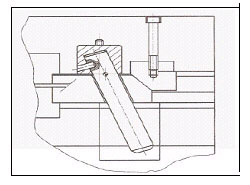

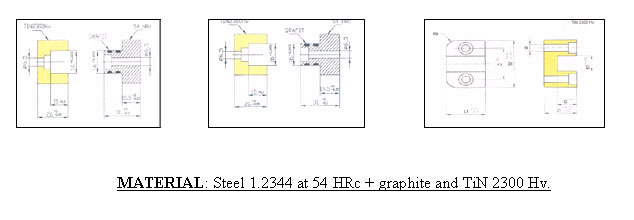

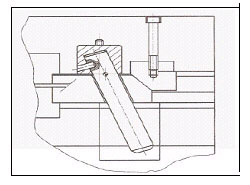

Inclined Assembly:

- The tilted assembly allows to make the allocations of tilted columns with great agility. - Its capability of getting fixed through the front side of the plate allows for an agile capacity of exchange.

- Over a period of experience in the injection mold designing and manufacturing the great need has been felt to improve its mechanization. Following from this and given the complexity of manufacturing the tilted columns in the moulds, BOLEXP has decided to manufacture these tilted / inclined assemblies.

- 140 models are available in stock, with 7 different degrees and 5 column diameters are available ex-stock at BOLEXP for ready delivery

- The assembly consists of a support in 1.2312 material screwed into the allocation previously made in the mould plate with 2 conical screws fixing and aligning the position of the tilted column out of the support.

- Mounting and unmounting operations are made through the front side of the plate, which makes it easy to exchange, when needed. The allocations to make on plates are always straight, so improving its mechanization agility.

- By using the BOLEXP tilted assembly, the down side of the plate is kept free, through which cooling circuits can be made without interferences

(For images, please see next pages)

For details contact:

Madhu Machines & Systems Pvt Ltd, Vadodara

Mr. Sabu Philip

Phone no:+91 265 2321104 / 2353886

Email Id: machinery@madhu-group.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}