For Sale - M - 1384 - Innovative Cooling Parts

Reference Numbers

M - 1384Product

Innovative Cooling Parts

Incorporation of 'WEMA' products in Plastic Injection mould ensures optimum production and quality of plastic products.

Important WEMA products for efficient cooling & ease of installation and maintenance in the mould are…

Water Plugs:

- Fast and secure installation and removal

- O-ring made of Viton® for higher temperature.

- Secure seal even under high pressure due to elastic metal ring

- Fast positioning in the mould

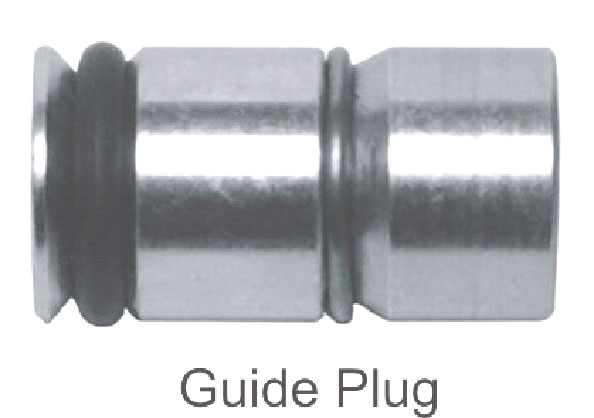

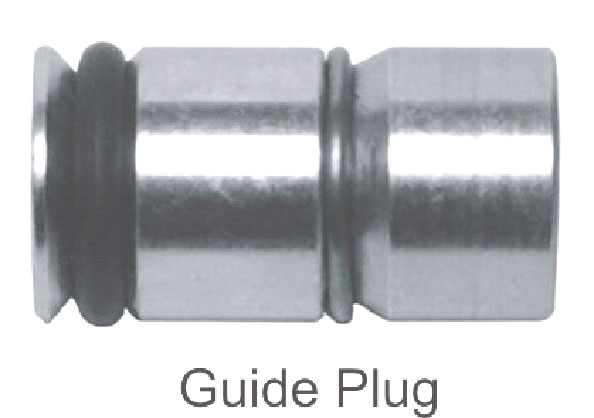

Guide Plugs:

- With Viton® O rings for high temperature.

- Fast and secure assembly and disassembly.

- Hermatic seal to prevent the penetration of coolants.

- Possible use with oversized bore diameters up to +0.5 mm

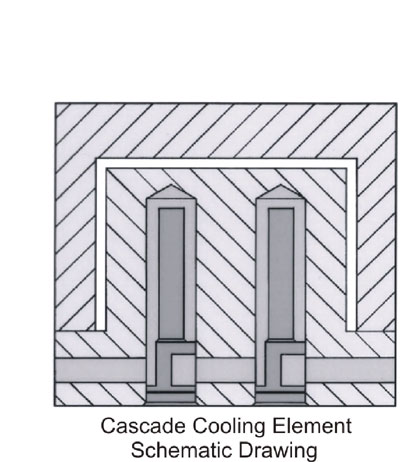

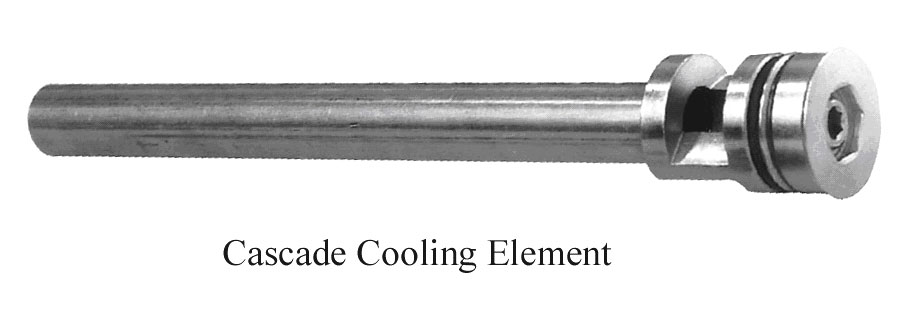

Cooling Elements for use in line:

- Easy and fast assembly and disassembly.

- Versatility of positioning due to the consistency of the inlet and outlet section of the element for the cooling liquids.

- Provided with the Viton® O ring for higher temperatures

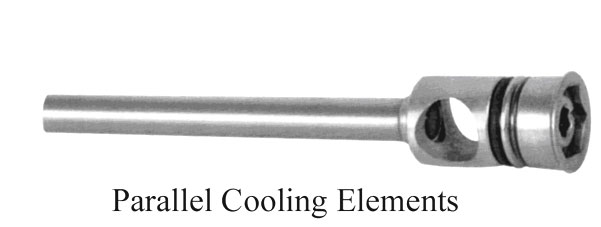

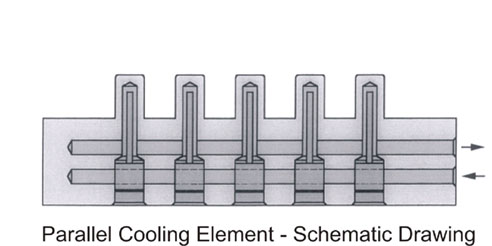

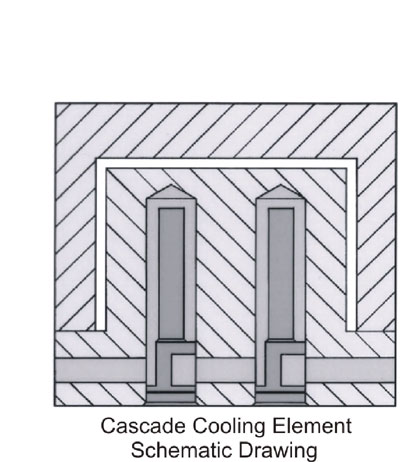

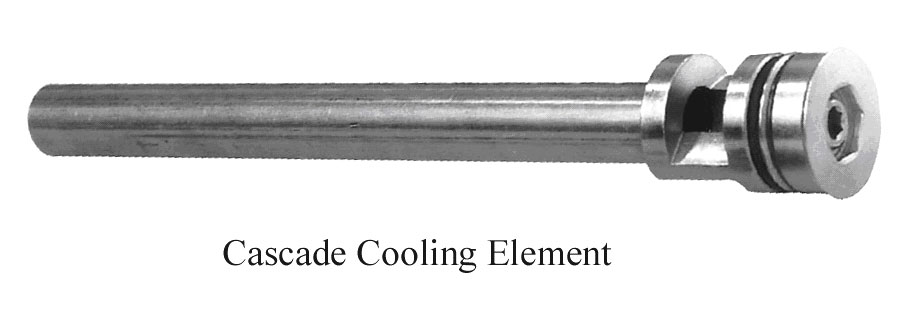

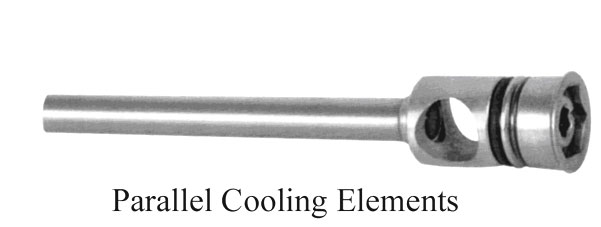

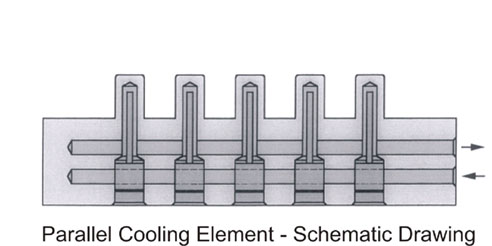

Cooling Elements for Parallel Cooling:

- Easy and fast assembly and disassembly.

- Versatility of positioning due to the consistency of the inlet and outlet section of the element for the cooling liquids.

- Provided with the Viton® O ring for higher temperatures.

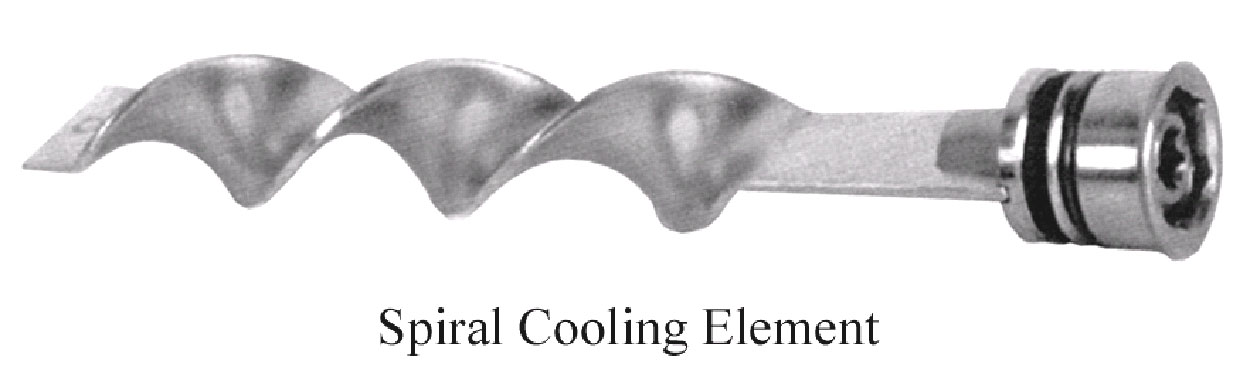

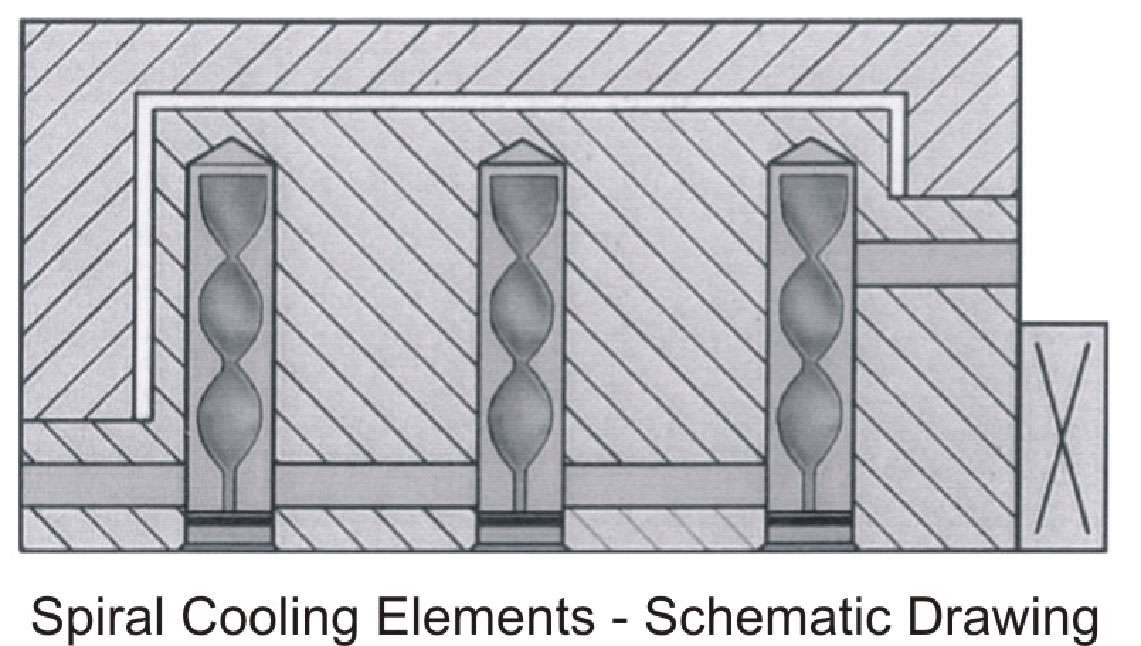

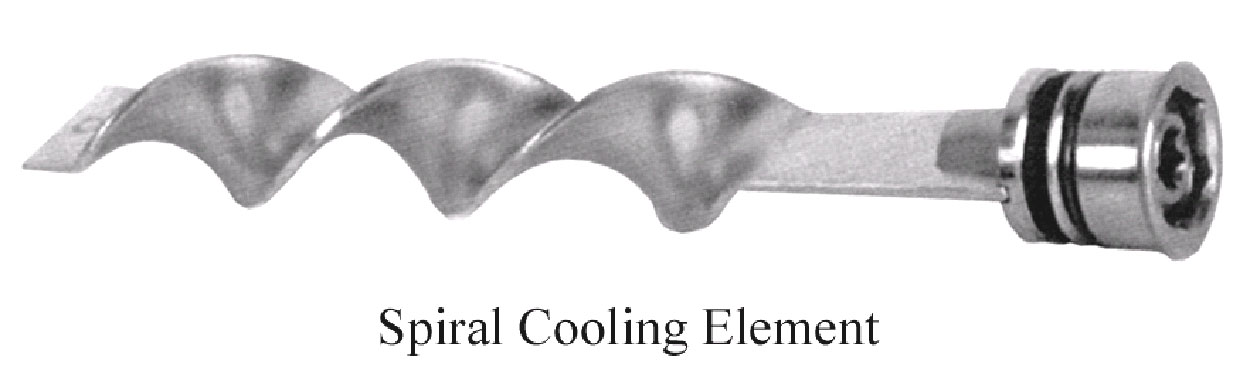

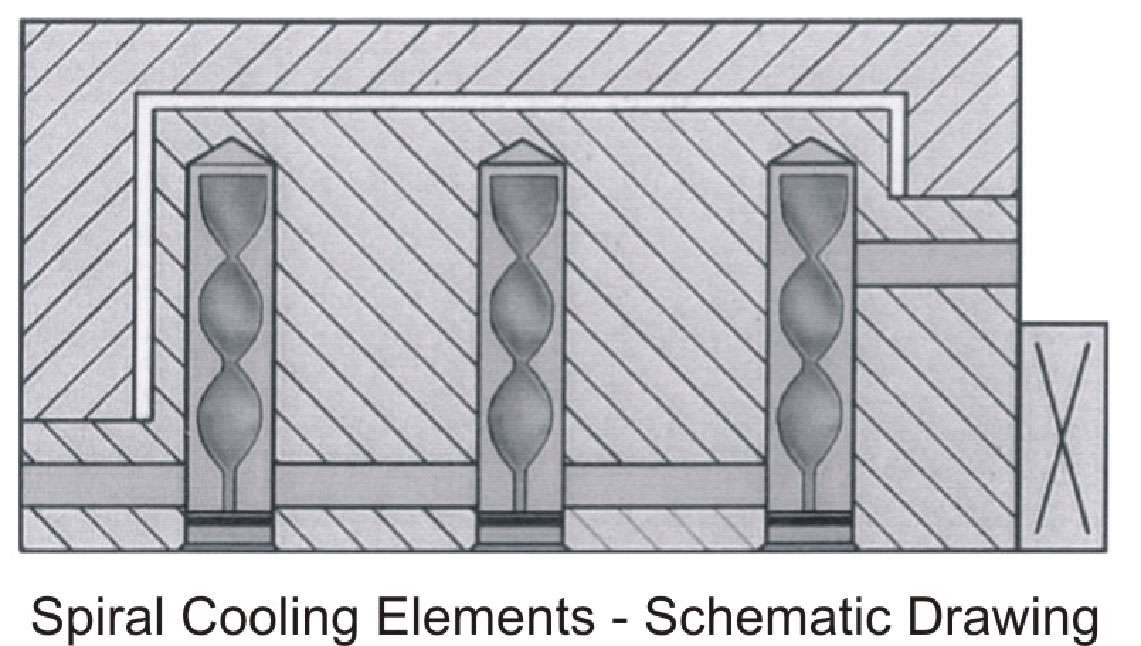

Spiral Cooling Elements:

- Easy and fast assembly and disassembly.

- Versatility of positioning due to the consistency of the inlet and outlet section of the element for the cooling liquids.

- Provided with the Viton® O ring for higher temperatures

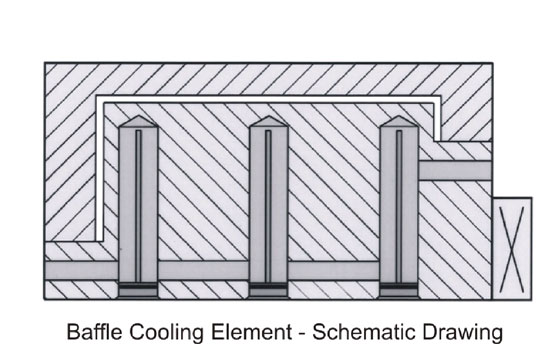

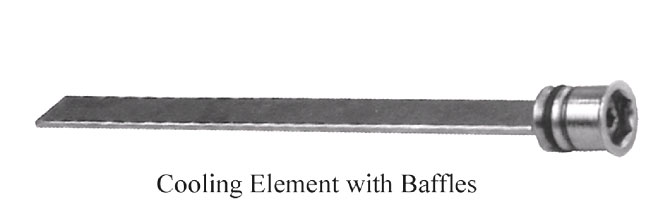

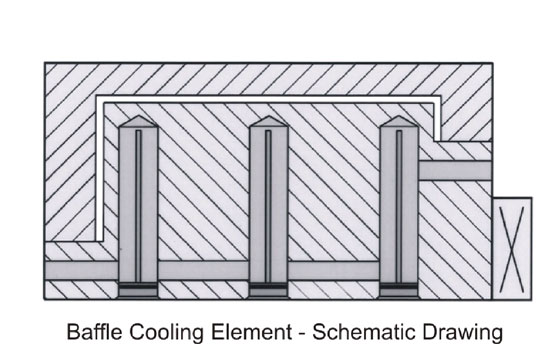

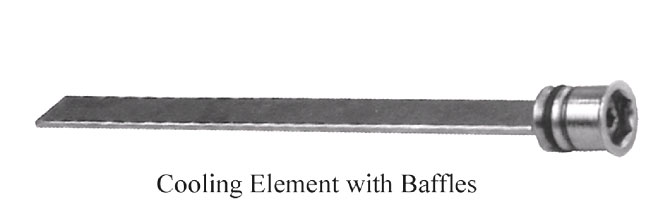

Baffle Cooling Elements:

- Easy and fast assembly and disassembly (using a simple drilling machine).

- Versatility of positioning due to the consistency of the inlet and outlet section of the element for the cooling liquids.

- Provided with the Viton® O ring for higher temperatures.

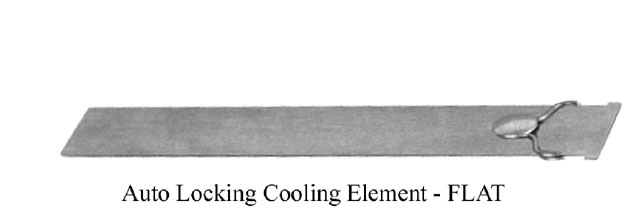

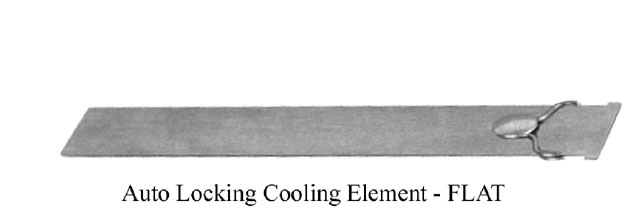

Auto Locking Baffles:

- Fast installation of core cooling with flat elements.

- Secure assembly even in oversized bore holes

- Easy disassembly for maintenance

- Made of Stainless Steel

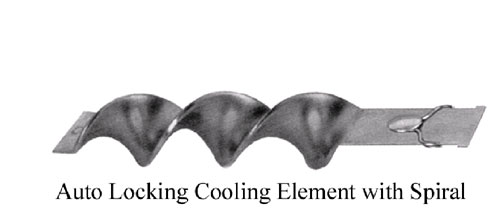

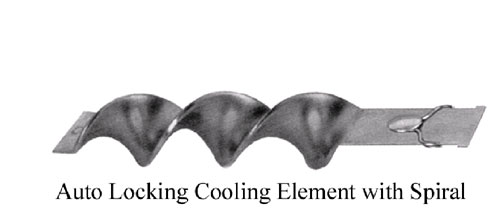

Auto Locking Spiral Cooling Elements:

- Fast installation of core cooling with spiral elements.

- Secure assembly even in oversized bore holes

- Easy disassembly for maintenance

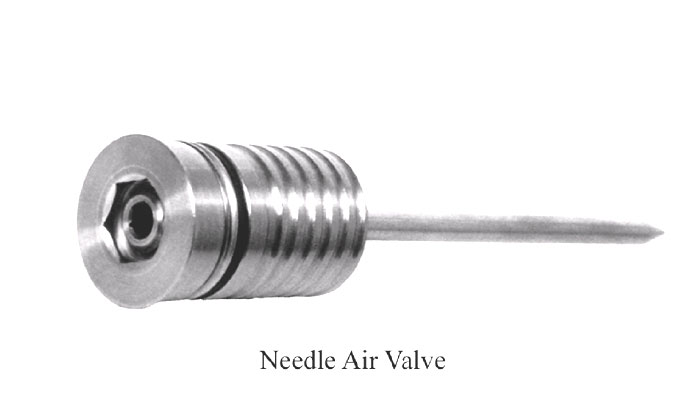

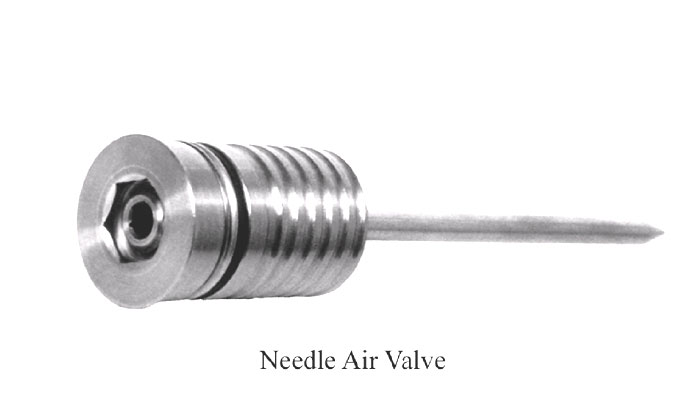

Needle Air Valve:

- Ideal for aesthetic surface of parts.

- Non clogging of blow out point

- Can be used as a self cleaning gas vent due to needle form by grinding

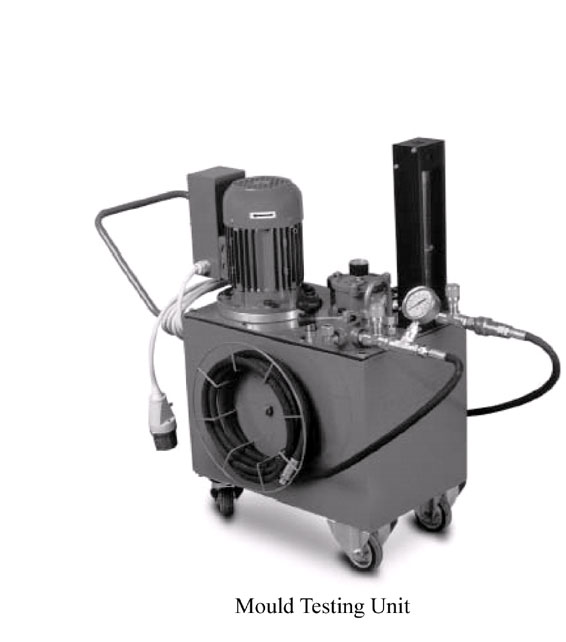

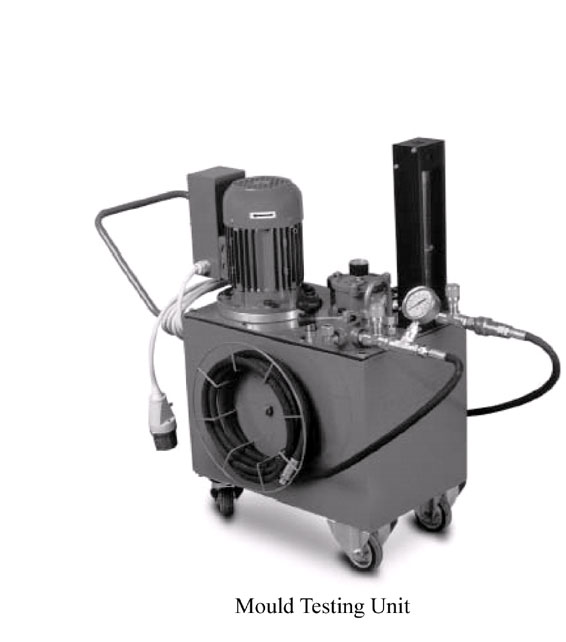

Mould Testing Unit for checking the mould cooling circuit.:

- Tank capacity 40 liters water with min. 30% glycol agent

- Electric motor pump

- Pre selection of pressure settings

- Flow Control (Flow Meter)

- Double filtering liquid with visual indication of filter condition.

- Air jet cleaning devices for the passages.

(For images, please see next pages)

For More Details Contact:

Madhu Machines & Systems Pvt Ltd, Vadodara

Mr. Sabu Philip

Phone no:+91 265 2321104 / 2353886

Email Id: machinery@madhu-group.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}