For Sale - PCM - 1697 - Three Arm Bi-Axial Machine

Reference Numbers

PCM - 1697Product

Three Arm Bi-Axial Machine

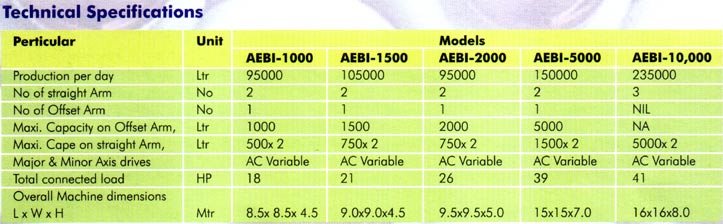

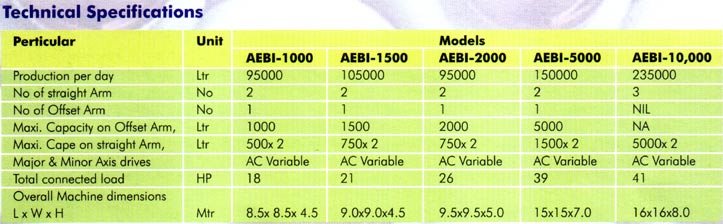

We manufacture Three Arm Bi-Axial Rotational Moulding machines from 500 to 10,000 Liter capacities.

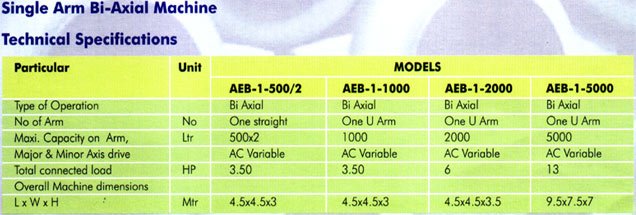

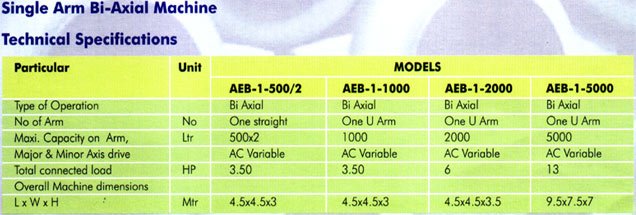

- Single Arm Bi-Axial machines from 500 to 10,000 Liter capacities.

- Rock-n-Roll Machines up to 25000 Liter capacities.

- Sheet metal moulds for all design of Roto Molded products.

- Micro fine Pulverizing systems from 40 Kgs to 350 Kgs/hr extrusion lines for coloring and compounding from 50 Kgs/hr to 125 Kgs/hr

- Granulators from 40 Kgs to 350 Kgs/hr.

Compounding Mixers from 60 Kgs to 300 Kgs/hr.

Three Arm Bi-Axial Machine, Salient Features:

-Most efficient in fuel and energy consumption compared to other types of machines.

-Very consistent product quality due to smooth Bi-axial rotation, highest production due to lowest cycle time.

-Uniform heating of the mould with forced air circulation in heating chamber.

-Uniform distribution of material hence possible to produce tank with lesser weight.

-Best compatibility in market due to lowest production cost per tank.

- Lowest rejection rate due to sound and proven technology.

- Clean and silent operation of machine.

- Flexibility to produce double and triple layer tanks.

- AC variable drives for all Minor and major axises for minute and accurate speed control

- Control panel is equipped with AC drives, Digital indicators, temperature controllers, timers and advance automation circuit for entire process control and all necessary safety features.

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}