For Sale - PCM - 1856 - Plastic Recylcing Machines

Reference Numbers

PCM - 1856Product

Plastic Recylcing Machines

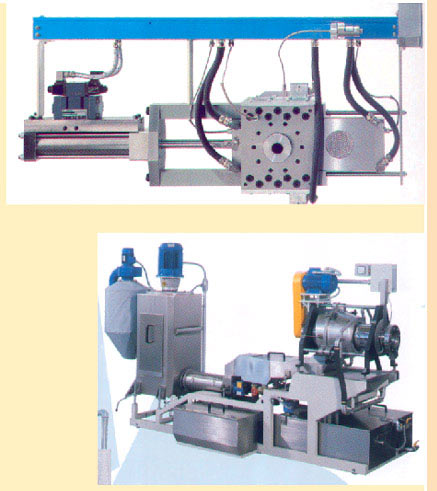

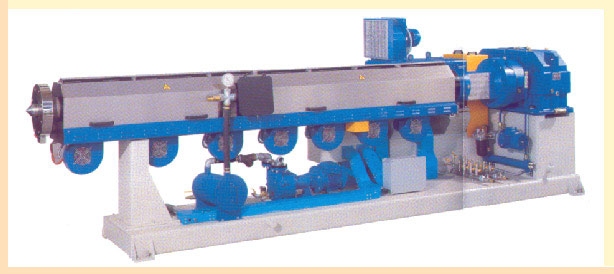

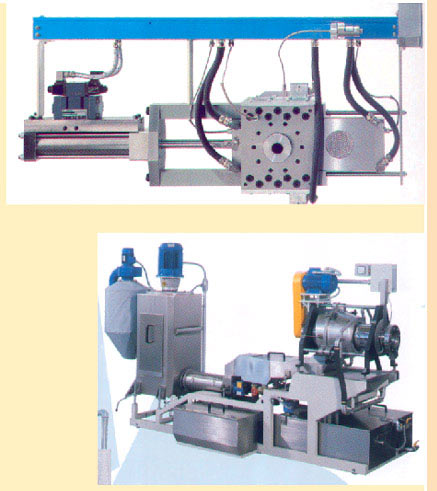

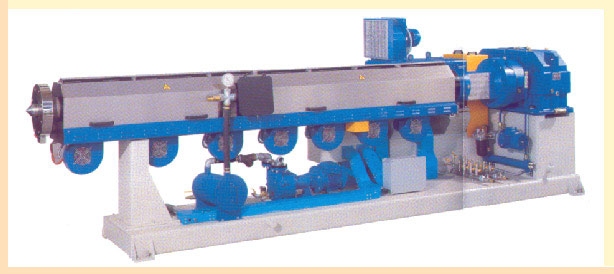

Regeneration Systems: The Satellite regeneration systems can be divided into three different types

- The conventional systems formed by a grinding / milling machine coupled with the forced hopper, extruder, filtration systems, die-head with spaghetti bath.

- The GMS systems, formed by a grinding / milling machine coupled with the forced hopper, extruder, filtration systems die face cutter, vibrating dryer, centrifuge and cyclone.

- The COMPAC systems of M/s. Gamma Meccanica srl. formed by a conveyor, shredder, extruder, filtration systems, die-face cutter, vibrating dryer, centrifuge and cyclone.

The extruders are designed with utmost care incorporating the High Tensile Compression Screw, Vacuum Vent, Temperature Control, Rotational Control, Constant Feeding and much more…

Features: The technological co-operation between M/s. Gamma Meccanica srl., Italy, and Satellite has packaged with it some excellent features, which we highlight below with Pride:

- Leading plastic recycles worldwide have come to rely on us to make their businesses more productive and more profitable.

- Our machines are more robust dependable, easy to use and ideally suited to produce uniform, high quality recycled plastics.

- The key is the advanced machine design combined with high output vented single screw extruders, die-face cutter technology, oleo-dynamic screen changers, force feeder technology, etc.

- This efficient process yields high volume production with ease of operation.

- Our die-face recycling technology delivers excellent quality granules with purity to its maximum and accurate cut virgin like pellets.

- High outputs as against small screw diameters with high speed are our prime target.

- The power consumption being very low against high outputs makes the processed material cheap.

- The Die face cutter cuts the shape of granules identical to a virgin granule, which permits the final consumer to get, improved processing and flow characteristics. This enhances the price of reprocessed material tremendously.

- The filter of the Screen Changer (Automatic) can be changed, on line thereby reducing the waste in time for the process to stop and restart for changing the filter.

- The automatic nature of the machine reduces the number of workers required to handle scrap, operate the machine, handling and packing finished granules, etc. The plant can be operated and run by one skilled and one unskilled worker at any time.

- Satellite has processed extremely contaminated and dusty material on the machines yet achieved extremely clean granules.

- Our R & D is always striving to innovate and upgrade the technology to get the maximum in quality and quantity. Quality, support and prompt service are the main goals of Satellite.

- To fulfill the goals satellite uses the support of the advanced information technology to stay closer to our customers at all times.

The main types of materials that can be regenerated by Satellite recycling systems are LLDPE, HDPE, LDPE, HMHDPE, EVA, PP, BOPP, OPP, PS, EPS, XPS, ABS, PC, PET, etc. furthermore, the cutting system can also be used to granulate further types of materials such as charged (filled) POM, PE, PP, TR, PVS, SBS, KRATON, PA, HOT MELT, etc.

For more information contact:

Satellite Plastic Industries

Mr. Rajiv / Haren Sanghavi

satellite@vsnl.com

Tel : +91 22 22006477

+91 22 66346816

Fax : +91 22 22006556

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}