For Sale - PCM - 2332 - Pipe Profile Plant

Reference Numbers

PCM - 2332Product

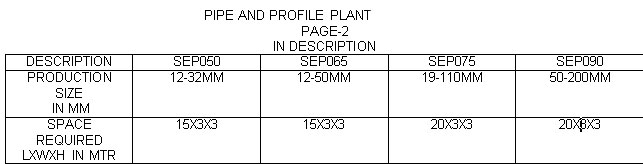

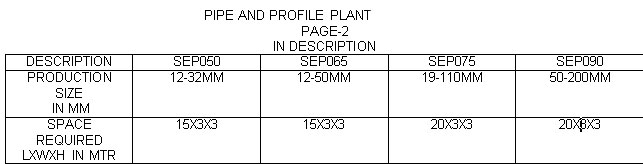

Pipe Profile Plant

Pipe Profile

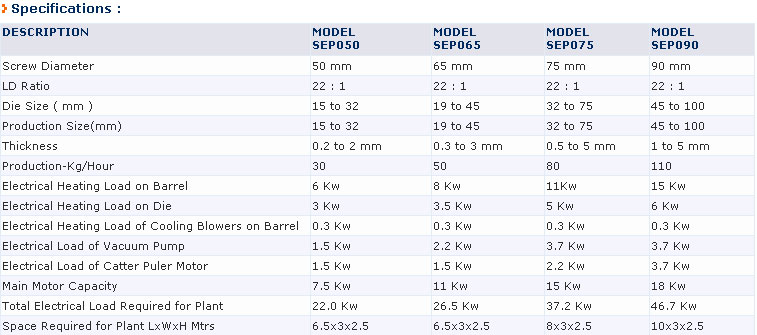

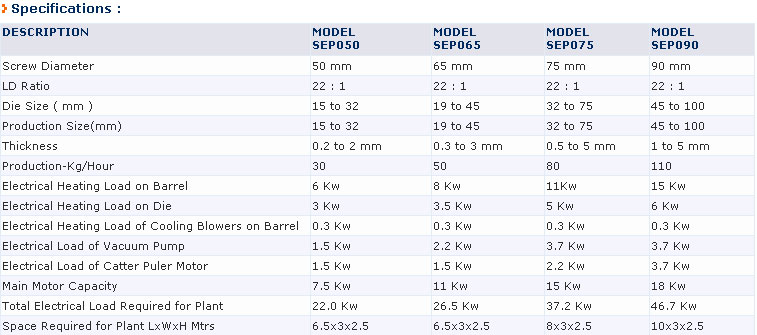

Extruder:

- This contains Screw and Barrel made from alloy steel duly nitrided and hard chrome plated for long life.

- Screw is fitted on suitable heavy thrust housing with thrust and roller bearing to withstand thrust pressure during extrusion. - Screw is driven by AC motor and coupled through a suitable standard make gear box. Barrel is divided into three zones for heating load distribution.

- Cooling blowers are provided on the barrel for all zones.

- Water circulating jacket is provided in feeding zone.

Die

- Die and adapter is made out from alloy steel and hard chrome plated.

Vacuum sizing chamber with cooling tank: - This unit is fabricated from the SS sheet. - Suitable size of vacuum pump and two sizers are fitted to maintain accurate size of the pipe.

Catter Puller

- This unit is used to pull pipe and equipped with specially designed rubber pulling belts. - Adjustable gap device is equipped to adjust the gap between two belts.

- AC motor of 2 HP capacities is coupled through a suitable reduction gear box to drive the belts.

Pipe Cutter

- Pipe cutter is equipped with 1 HP motor and pedestal with Limit switch and length adjuster are also provided with stand.

Plastic Scrap Grinder:

- Control panel is comprises of Microprocessor based digital temperature controllers to control the temperature on barrel and die

- All AC motors are driven by Frequency inverter for long life.

- Suitable switch gears are provided to get the optimum performance of the machine.

Control Panel

- Control panel is comprises of Microprocessor based Digital Temperature controllers to control the temperature on barrel and die

- All AC motors are driven by thyristorised AC drive to get the better speed control. Main AC motor gets the optimum performance of the machine.

(For more details and picture, please see next pages)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}