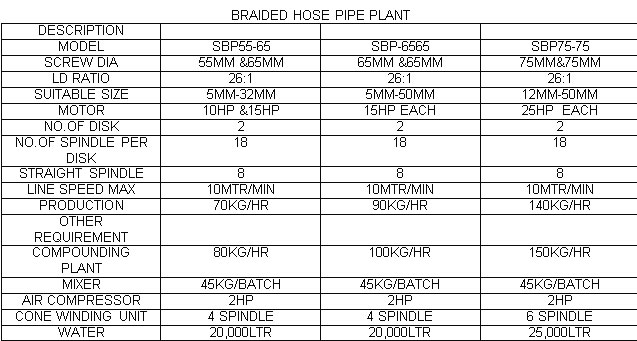

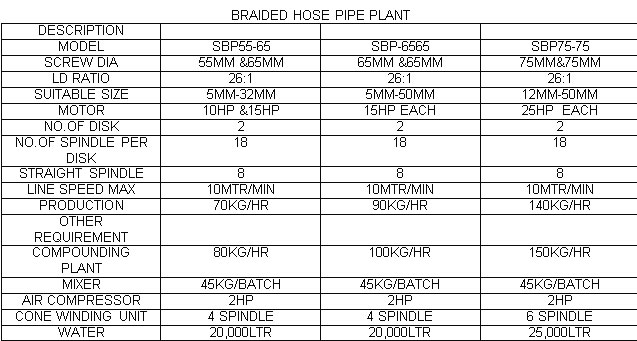

For Sale - PCM - 2334 - Braided Hose Pipe Plant

Reference Numbers

PCM - 2334Product

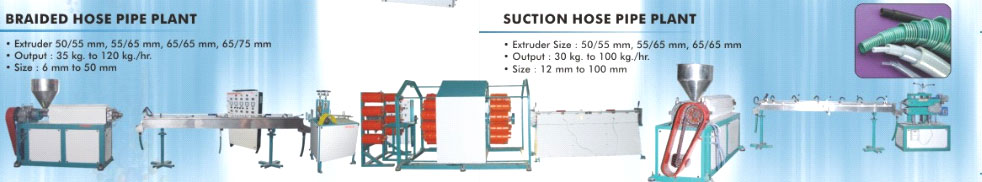

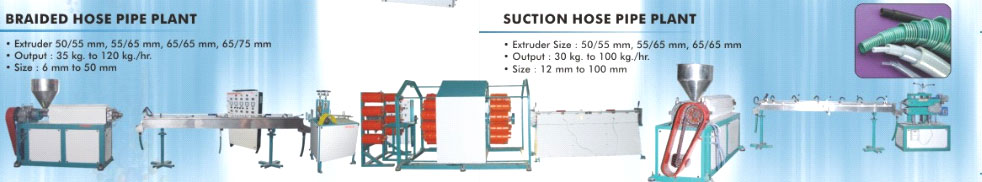

Braided Hose Pipe Plant

Extruder (2 Nos.): Stand fabricated heavy duty Ms Structure

- Material (Screw & Barrel): Nitrided Nitro Alloy Steel

- Cooling: Jacketed water cooling system on feed zone.

- All zones of barrel cooling by 0.3 KW Air Blower

- Heating Zones: 5 + 6 = 11 No

- Heaters: BEND type heaters are mounted on the barrel. The barrel is covered by mild steel cover and it powder coated.

- Hopper: Fabricated from S.S. Sheets with a glass window for visual inspection Of the raw material level provided.

- Reduction Gear Box: helical type with inbuilt thrust bearing housing incorporated within The main gearbox to withstand the thrust developed during extrusion.

Screw:

- Screw is made from alloy steel and to be hardened and chrome plated.

- It is fitted on a heavy thrust gear box to withstand the pressure during extruding the TUBE

- Screw is driven by induction motor / AC motor / Ac variable speed drive through a suitable gear box of standard make.

Barrel

- Barrel is made from alloy steel and nitride hardened, and precisely honed to fine inner surface.

- Water circulation jacket is provided with hopper in feeding zone.

- Barrel is divided in to specified zones for heating .

Die:

- Die is made from S.S. & nitro alloy material and it treated specially and hard chrome plated to required portion.

Water tank

- Water tank is fabricated from stainless steel.

- Tank is fixed on sturdy steel fabricated (2 NOS.) structure.

- Tank height adjustment facility and castors on tank stand legs provided.

- Stainless steel support rollers provided with the tank

Tube pullar

- This unit is used to pull tube and equipped with specially designed rubber rolls.

- Adjustable gap device is equipped to adjust the gap between two rolls. A.C. motor of 2 HP capacity is coupled through a suitable reduction gear box to drive the rolls.

Haul off

- This unit is used to pull pipe and equipped with specially designed rubber rolls.

- Adjustable gap device is equipped to adjust the gap between two rolls. A.C. motor of 2 HP capacity is coupled through a suitable reduction gear box to drive the rolls.

Temperature control panel

- Temperature control panel consists of Individual digital temperature controllers facility with SSRS, Fuses, switches and Amp.

- Meters for required number of zones. A/C DRIVE : ABB/ Delta / Control Teknik make

Wiring

- Wiring between our supplied panels and machine according to our standard foundation layout is included in the standard scope of supply.

Braided

- Braided having 44 spool, one side having 18 spool running in clockwise direction and second side 18 spool running in anticlockwise direction.

- 8 spool having straight winding.

- Complete assembly is run by 4 hp AC Motor.

- AC motor with gearbox: Siemens / Bharat Bijlee make.

Gumming unit

- For joining the pipe inner layer and second pipe outer layer through chemical with thread.

Oven

- Oven is made from M.S. Pipe jacketed with heater for drying the chemical and proper homogenous of both pipe joint

- This unit is divided in two zones.

Cone winder

- For winding the thread in cone type four station cone winder with motor and gearbox assembly connected with tensioner

Braided Hose Pipe Application

- Braided Hoses are widely used in Agriculture, Drainage Systems, Chemical Industry, Construction Oil and many other industries.

- PVC Braided Hose is strong enough to withstand high pressure.

- It is light in weight than rubber hose and its smooth inner surface permits easy fluid flow.

- Its excellent transparency allows air locks, ensures detection of blockage in less time and hence saves costly down time.

- It is also useful for air - pneumatic - water and chemical applications

For more details and images, please see next pages

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}