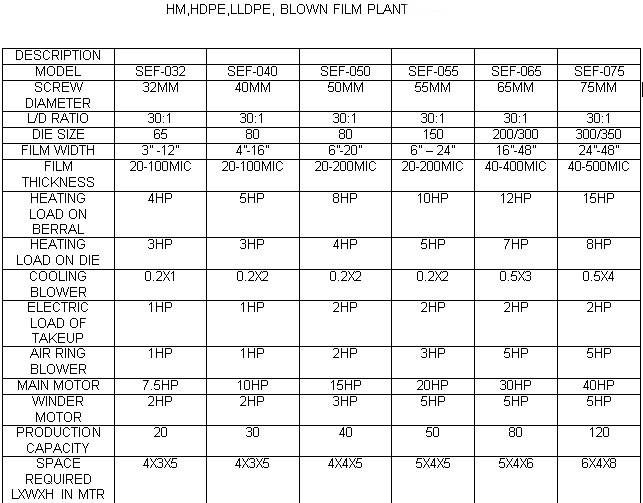

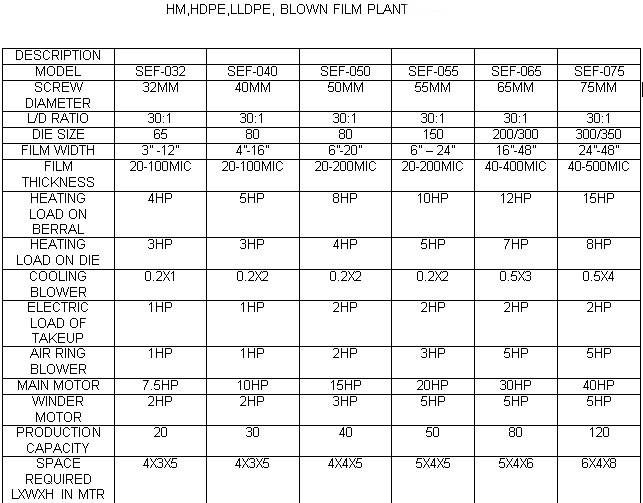

For Sale - PCM - 2336 - Blown Film Plant

Reference Numbers

PCM - 2336Product

Blown Film Plant

- Our Blown film Extruder contains Screw and Barrel made from alloy steel duly nitrided and hard chrome plated for long life.

- Screw is fitted on suitable heavy thrust housing with thrust and roller bearing to withstand thrust pressure during extrusion. - Screw is driven by AC motor and coupled through a suitable standard make gear box. - Barrel is divided into three zones for heating load distribution.

- Cooling blowers are provided on the barrel for all zones.

- Water circulating jacket is provided in feeding zone.

Die:

- Die and adapter is made out from alloy steel and hard chrome plated.

Air Ring:

- This unit is fabricated from the Aluminum alloy.

- Suitable for the die to maintain the accurate size of the film width.

Take off Unit:

- This unit is used to pull film extruded from the die and equipped with specially designed rubber and abonite rolls.

- Pneumatically operated adjustable gap device is equipped to adjust the gap between two rolls.

- DC motor of 1 HP capacity is coupled through a suitable reduction gear box to drive the rolls.

Winder:

- Surface winder or Film winder is supplied along with the plant as per the requirements of the customer to suit the application. - Abonite and rubber rolls are provided for the perfect winding of the film.

- These rolls are driven by a 1 HP AC motor. Torque motor station winders are also provided for the final winding of the film.

Control Panel:

- Control panel is comprises of Microprocessor based Digital Temperature controllers to control the temperature on barrel and die.

- All AC motors are driven by thyristorised AC drive to get the better speed control.

- Main AC motor is driven by Frequency Inverter for long life.

- Suitable switch gears are provided to get the optimum performance of the machine.

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}