For Sale - PCM - 2339 - Co-Rotating Twin Screw Segmented Extruder

Reference Numbers

PCM - 2339Product

Co-Rotating Twin Screw Segmented Extruder

We manufcture extrusers with

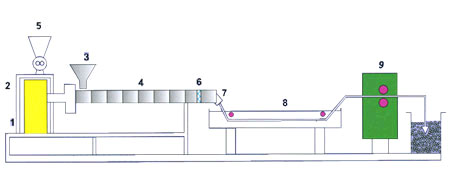

Segmented Barrel:

- Barrel segments are from rectangular shaped blocks.

- Barrel is made from alloy steel and nitride hardened and precisely honed to fine inner surface.

- The character 8 shaped barrel bore provide helical material transport and continuous material transfer so we can get higher output from our intermeshing twin screw extruder. - Water circulation system is provided with every modular of barrel.

- Each barrel sector has an housing for the probe for the working temperature control and measurement.

Gearbox:

- The gearbox is specially designed for intermeshing, co-rotating twin screw extruder.

- The gearbox is of our own design and manufacture.

- The gearbox is divided in to four parts due to get good accuracy and long life features. - Our good sense of bearing selection increases the life of gearbox.

- Shaft, gear and bearings are assembled in each zone of gearbox.

- The gearbox is cooled and lubricated by a motor and oil pump.

- The heat exchanger is also providing for cooling of oil.

Barrel Cooling System:

- Barrel is cooled by water and composed by modular sectors.

- Each modular has different types of holes for fit together barrel sectors and water cooling.

- The inlet and outlets of each modular are connected the relative delivery and return, Individual pumps are used for the control of water circulation and controlled by panel.

Segmented Screw:

- Our Screw design is built on a modular system to get the advantages of different configurations in process section that allow the best combination for every application. - Screw is made from special type nitride steel material and through hardening and also providing coating to solve wear and abrasion problems.

- The life of these modular screws is several times higher than ordinary materials.

- Screw sectors are mounting on a shaft with key way or spline.

- We preferred 2 lobe screw design for low shear and high output compounding.

- Screw segment are wiping, mixing, conveying and kneading type are provide. - Spark's screw and kneading elements ensure that extruder runs with minimum downtime.

For more details & image please see next pages

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}