For Sale - PCM - 2761 - Full Automation Injection Blow Molding Machine

Reference Numbers

PCM - 2761Product

Full Automation Injection Blow Molding Machine

This equipment is a one-step full automatic injection blow-molding machine, which is applicable to the processing of thermoplastic materials e.g. PE, PP, PS (SAN, PMMA, PC, PETG, PEN). It is widely used in manufacturing packaging bottles for pharmaceutical, healthcare products, food and beverage, cosmetic and other industries.

This machine has multi-cavities in one mold which can perform continuous production full automatically. It adopts horizontal three working stations index head, hot runner system and multi-stage injection molding system. Plastic injection, blowing and stripping stations act simultaneously to guarantee the equipment operates high efficiently and saves energy. It ensures the flatness of bottle mouth and high precision of the internal and external diameter and the thread of bottleneck, without any scrap. It is the standard equipment for modern environment protection production.

- Lowering design of mold clamping cylinders ensures the products cleanness and easy mold replacement. Upper and lower clamping force is balanced inside the mold to make the mold uniform in force receiving. The rigidity of mechanical system is high.

- Unique Prefill technology and variable displacement pump pressurizing technology are applied to hydraulic system to achieve high efficiency and energy-saving operation.

- Special plasticization components suitable for both traditional multi-stage injection & multi-stage pack holding technology and special extrusion injection & multi-stage pack holding technology required by different materials.

- B & R control system specialize for plastic machinery, with the function of PID intelligent dynamic temperature control, authorization password protection, 999 groups of technology parameter storage and momentary supervision on the operation of the machine.

- Stripper station adopts long-distance digital laser sensor for detection, realizing unmanned automatic operation.

- Injection mold and blowing mold are made of high class stainless steel and magnesium-Aluminum alloy respectively. They are processed by special high precision numerical control equipment and fully guarantee the quality of bottle product.

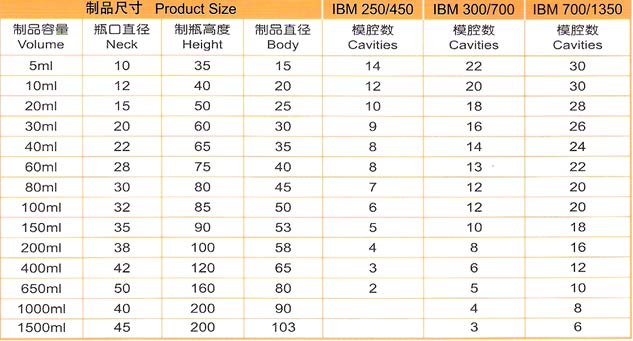

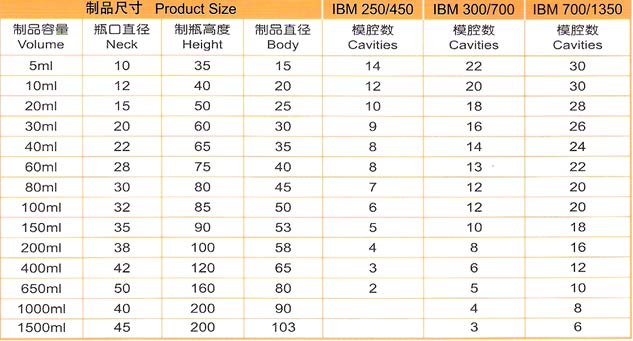

Technical Data

- Screw Diameter: 45 to 70 mm

- Injection Capacity: 250 to 700 cm3 max

- Injection Clamping Force: 460 to 1240 kN

- Blow Clamping Force: 75 to 200 kN

- Total Power: 34 to 73 kW

- Operating Power: 52 - 70 Percentages

- Hydraulic Working Pressure: 14.5 MPA

- Compressed Air Pressure: 0.7 ~ 0.9 MPA

- Cooling Water Pressure: 0.3 ~ 0.4 MPA

- Product Diameter (max.): 100 mm

- Product Length (max.): 200 mm

- Overall Dimension (LxWxH): 400x150x180 to 500x220x205 cm

- Weight Approx:5 to 12 t

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}