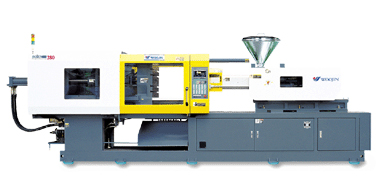

For Sale - PCM - 3001 - High-Speed, Precision & Energy-Efficient Injection Molding Machine

Reference Numbers

PCM - 3001Product

High-Speed, Precision & Energy-Efficient Injection Molding Machine

Model: Selex NS

Comes with closed-loop servo pumps for feedback controls, presenting excellent reproducibility and responsiveness, allowing precision control, high speed molding open and close, and more than 30 percent power savings compared to machines of similar functions.

- Use of variable piston pumps for close-loop feed-back control results in excellent responsiveness and reproducibility.

- Closed-loop system Speed pressure preset by controller is transferred to the pump control valve and is compared to actual value from sensor for corrective feedback.

- Vain pumps used in other machines does not allow output volume by pump itself, resulting in excessive heat and power loss.

- Variable pumps allows only output necessary for process, resulting in minimal power usage. (Power savings of more than 30 percent over vain pumps.)

Injection unit:

- Position transducer with excellent reproducibility allows accurate control of multi-stage speed and pressure levels.

- Automated material change saves time in raw material coloring material changing, thus improving efficiency.

- PID (Proportional integration & differentiation) temperature control standard with high responsiveness to temperature variations enables accurate and stable molding processes.

- Optional high-mixing screw minimizes wearing and corrosion from use of common screw and plastic raw material.

- Moveable injection bed allows easy installation of screw or cylinder options.

Controller:

Manufactured with state-of-the-art electronic control technology for a high precision and stability, it is suitable for multi-functioned injection molding machines.

User-friendly display and design for easy and simple operation.

- TMP 68301, 16bit micro processor

- PID automatic temperature control

- Dual processor program control

- Printer port

- 10.4" TFT color LCD monitor

Hydraulic unit:

- Compact hydraulic circuit allows easy repair & maintenance.

- Faster responsiveness and impact reduction during operation thanks to the cartridge valves.

- Precision molding with mold protection circuit.

- Precise plasticizing by proportional back pressure allows high-precision molding.

Clamping unit:

- T-groove reduces mold attach time, improving work efficiency.

- Automated mold adjustment allows rapid & convenient mold changes.

- Three-way safety devices of mechanical, hydraulic and electric means to ensure operator safety.

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}