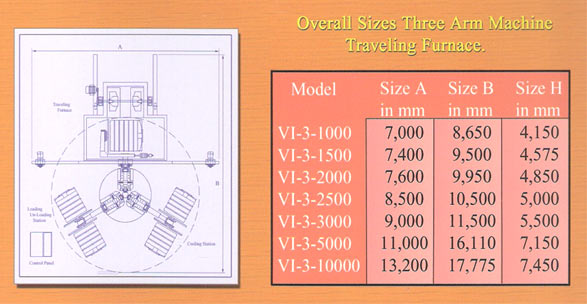

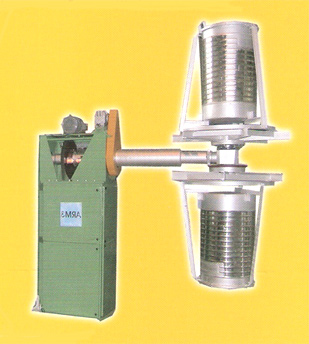

For Sale - PCM - 3229 - 3 Arm Biaxial Roto Moulding Machine

Reference Numbers

PCM - 3229Product

3 Arm Biaxial Roto Moulding Machine

Three arms bi-axial are three station machines with fixed turret and fixed oven. These are most versatile rotational moulding machine and most suited for high volume production. Cost of production is lowest for entire range of production. Large tanks can be mounted on L Arm and multiple smaller tanks can be mounted on straight arm. This flexibility is very useful for catering to varying demand of market. World over three arm machines are backbone of rotational moulding industry. Engineers at Vinodrai Inc perfected the art of making most productive, fuel efficient, and user friendly three arm machines.

- Closed oven with optimized forced air circulation for uniform heating of mould.

- Automation of door opening, closing and turret indexing.

- Fuel efficient Italian package burner with auto ignition.

- Temperature, RPM and cycle time controlled by advance control panel.

- Lowest cycle time, highest per shift production.

- Designed to produce double layer, triple layer and insulated tanks.

- Capable for producing tanks in less material because of even distribution of material.

- Heavy duty L arm and Straight arm.

- No in process rejection.

- Low fuel and electric energy cost.

- Clean working environment.

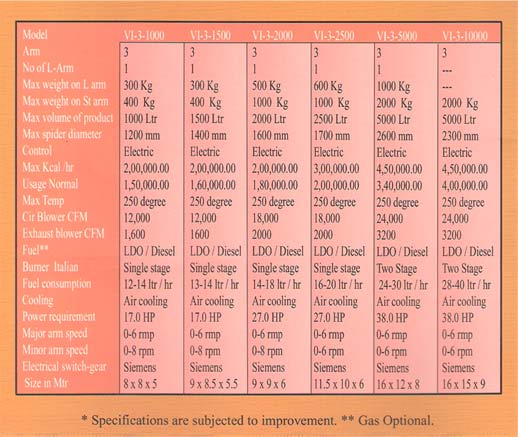

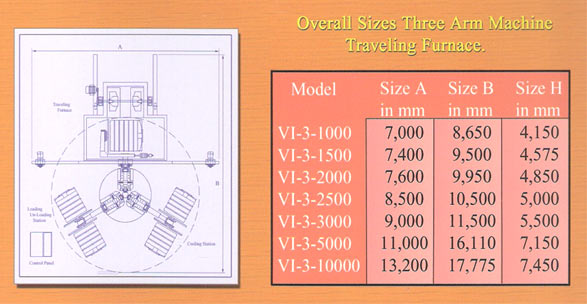

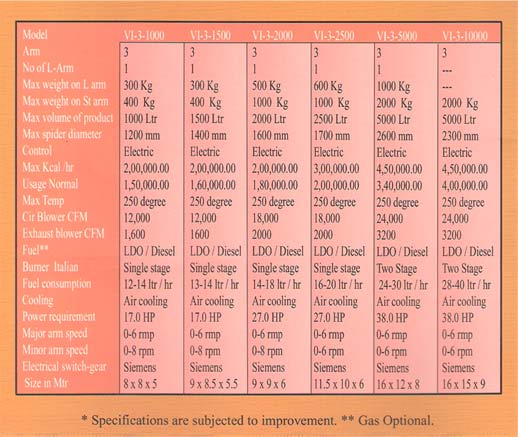

Vinodrai is manufacturing largest range of three arm machines with capacity from 1000 lit to 10,000 lit. Models up to VI-3-5000 are with one L-arm and two Straight arms. VI-3-10000 is with all three Straight arms.

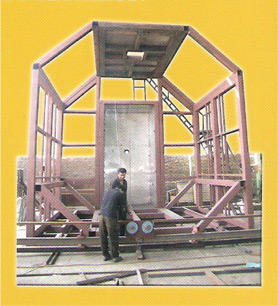

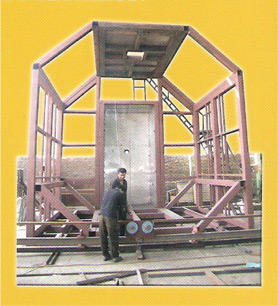

Furnace:

Furnace is fabricated from insulation filled ERW square and rectangle structure. Structure is dimensionally stable under years of heating and cooling stress and strain. Combustion chamber is lined with stainless steel sheet. Twin re-circulating blowers are constructed from stainless steel and are dynamically balanced. Heavy-duty geared motors operate doors; advanced clutch protects complete system from any overload.

Safety railing and stairs is provided for loading material from top. Inching push button station located at the top of furnaces allows alignment of mould for loading of multi-layer material from top.

Burner:

State of the art Riello make Italian burner runs on Diesel. Auto Ignition, flame failure protection, efficient smokeless burning of fuel is highlight of these burners. LPG or Propane burners also provided upon request.

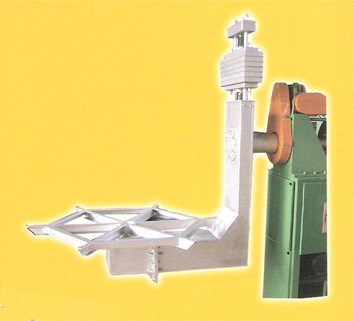

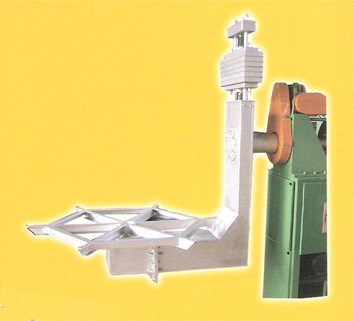

L Arm:

L Arm is constructed using 10mm tested m.s. sheet. Balancing mechanism is rugged and simple to adjust. L Arm is mounted on heavy duty bearings, gearbox and transmission gives long trouble free service.

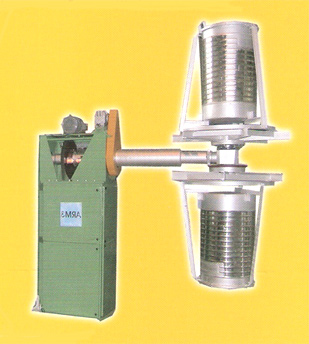

Straight Arm:

Large diameter, ultrasonically tested shaft is back bone of Straight Arm. Heavy duty bearings, gearbox and transmission gives long trouble free service.

Turret:

Machined base ring and heavy rotating base plate insures smooth indexing of turret. Turret is rotated by overload protected, heavy duty geared motor. Optionally we also provide pneumatic operated.

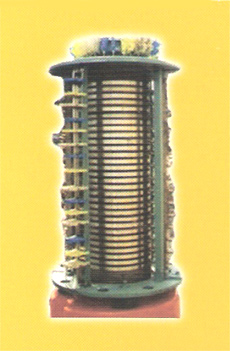

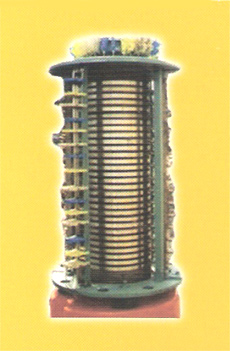

Slip Ring Assembly:

Uninterrupted electrical supply is available to rotating arm assemblies through Slip Ring Assembly. Specially designed for rotational moulding machine for trouble free operations for years together.

Control Panel:

Control panel is sheet steel; powder coated housing enclosing all controls. Free standing ergonomically designed. AC drives for X and Y axis. Digital display of RPM setting. Reversal switch, digital temperature controller, easy to adjust cycle timer, overload protection, and alarm assist in process control.

Circuit is designed to take over process control. So even a unskilled operator gives the same quality of tank. A circuit diagram with wire numbers and trouble shooting guide helps in quick diagnosis of faults.

(For more details and images, please see next pages)

For More Details Contact:

Vinodrai Engineers Pvt. Ltd.

www.vinodrai.com

Mr. Sunil Raithatha

Tel.: +91-2482 262000, 262400

Mobile: +91-9890260111

E-mail: vinodraieng@rediffmail.com, sunil@vinodrai.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}