For Sale - PCM - 3232 - EN Series Single Station Roto Molding Machine

Reference Numbers

PCM - 3232Product

EN Series Single Station Roto Molding Machine

Vinodrai introduces dream machine for water storage tank manufacturers of India, a single station machine EN 1000 x 2 with multi-station capabilities. EN 1000 x 2 is truly multi-station capable machine with capacity to mould two tanks of 1000 lit. at a time or four tanks of 500 lit. at a time. Resulting in increased production at lowest ever fuel cost.

Followings are few highlights of the features of this machine.

- Single station Bi-Axial machine.

- Lowest foot print, very small space is required for installation.

- Only 3.5 H.P. power required.

- Available for single or three phase supply.

- Low fuel cost, 3.0 to 3.5 lit of fuel per tank.

- Power consumption less than 2.5 KWH per tank.

- User friendly machine, even unskilled operator can run the machine. Low manpower cost.

- Designed to produce double layer, triple layer and insulated tanks.

- Capable for producing tanks in less material because of even distribution of material.

- No in process rejection.

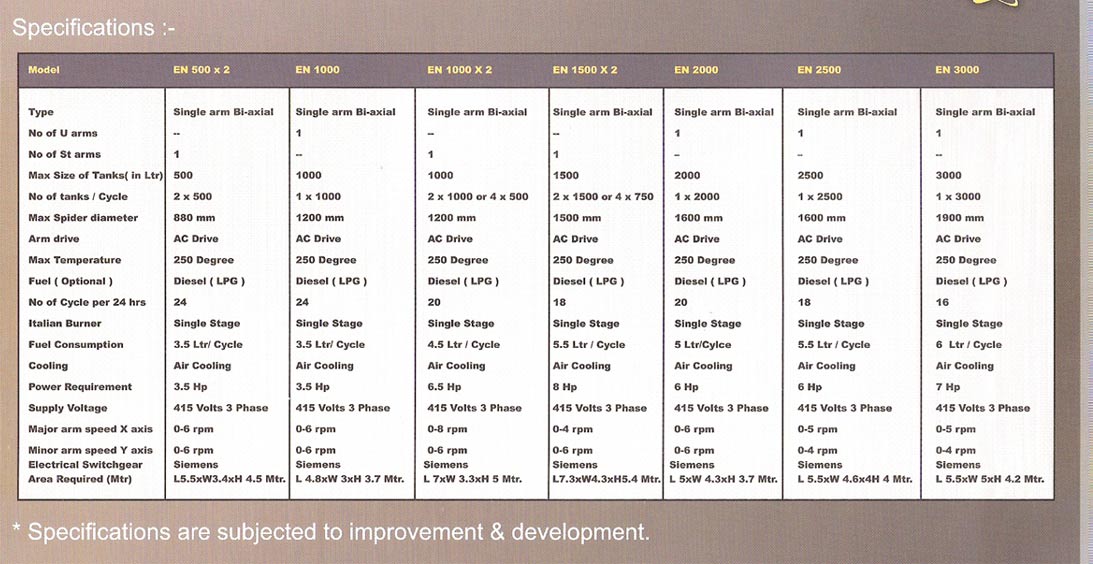

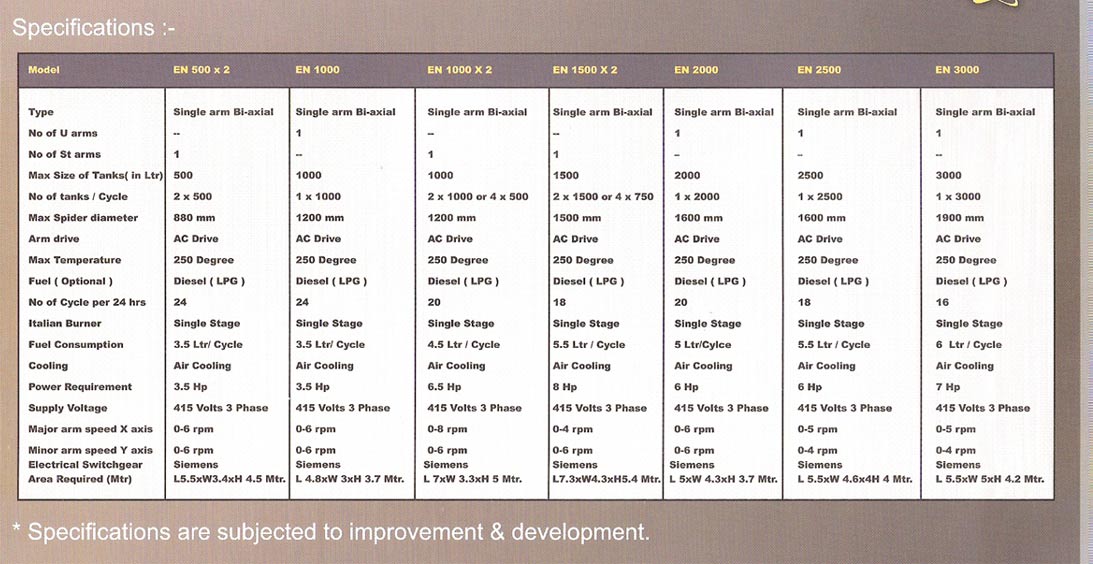

Technical specifications of EN series single station roto moulding machines:

1) EN 500 x 2:

- Control panel: AC motor with AC drive

- Firing system: Oil fire burner with auto cutoff with temp.

- Insulation: 75mm thick mineral wool insulation with SS inside

- Max. capacity: 500 ltr.

- Suitable for: 500 ltr. x 2 nos. or 300 ltr. x 2 nos.

Operating parameters:

- Power requirement: 3.5 HP (415 volt 3 phase)

- Process temperature: 210 degree

- Manpower: 2 semi skilled persons

- Heating time: 25 mins.

- Cooling time: 20 mins.

- Loading unloading time: 15 mins.

- Total cycle time: 60 mins.

- Fuel: High speed diesel

- Fuel requirement: 3.5 ltr. / cycle

- Fuel for any size of tank: 1.75 ltr. / tank

2) EN 1000:

- Control panel: AC motor with AC drive

- Firing system: Oil fire burner with auto cutoff with temp.

- Insulation: 75mm thick mineral wool insulation with SS inside

- Max. capacity: 1000 ltr.

- Suitable for: 1000 ltr. x 1 no. or 750 ltr. x 1 no. or 500 ltr. x 1 no. or 300 ltr. x 1 no.

Operating parameters:

- Power requirement: 3.5 HP (415 volt 3 phase)

- Process temperature: 210 degree

- Manpower: 2 semi skilled persons

- Heating time: 25 mins.

- Cooling time: 20 mins.

- Loading unloading time: 15 mins.

- Total cycle time: 60 mins.

- Fuel: High speed diesel

- Fuel requirement: 3.5 ltr. / cycle

- Fuel for any size of tank: 3.5 ltr. / tank

3) EN 1000 x 2:

- Control panel: AC motor with AC drive

- Firing system: Oil fire burner with auto cutoff with temp.

- Insulation: 75mm thick mineral wool insulation with SS inside

- Max. capacity: 1000 ltr.

- Suitable for: 1000 ltr. x 2 nos. or 750 ltr. x 2 nos. or 500 ltr. x 4 nos. or 300 ltr. x 4 nos.

Operating parameters:

- Power requirement: 6 HP (415 volt 3 phase)

- Process temperature: 210 degree

- Manpower: 2 semi skilled persons

- Heating time: 25 mins.

- Cooling time: 20 mins.

- Loading unloading time: 20 mins.

- Total cycle time: 65 mins.

- Fuel: High speed diesel

- Fuel requirement: 4.5 ltr. / cycle

- Fuel for 1000/750 of tank: 2.25 ltr. / tank

- Fuel for 500/300 of tank: 1.1 ltr. / tank

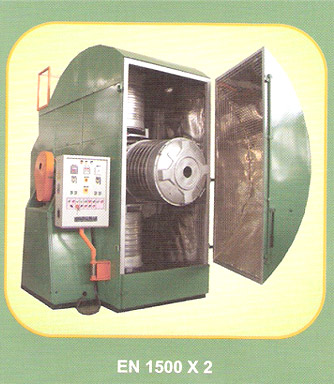

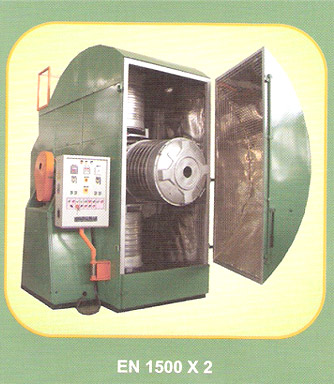

4) EN 1500 x 2

- Control panel: AC Motor with AC drive

- Firing system: Oil fire burner with auto cutoff with temp.

- Insulation: 75mm thick mineral wool insulation with SS inside

- Max. capacity: 1500 ltr.

- Suitable for: 1500 ltr. x 2 nos. or 1000 ltr. x 2 nos. or 750 ltr. x 4 nos. or 500 ltr. x 4 nos. or 300 ltr. x 4 nos.

Operating parameters:

- Power requirement: 8 HP (415 volt 3 phase)

- Process temperature: 210 degree

- Manpower: 2 semi skilled persons

- Heating time: 30 mins.

- Cooling time: 20 mins.

- Loading unloading time: 20 mins.

- Total cycle time: 70 mins.

- Fuel: High speed diesel

- Fuel requirement: 5.5 ltr. / cycle

- Fuel for 1500/1000 of tank: 2.75 ltr. / tank

- Fuel for 750/500 of tank: 1.4 ltr. / tank

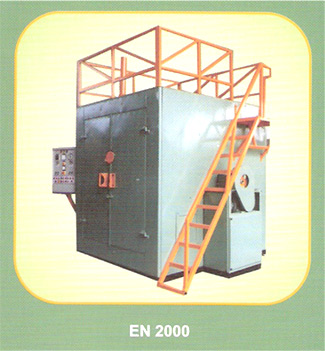

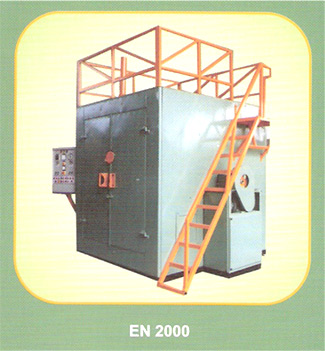

5) EN 2000

- Control panel: AC Motor with AC drive

- Firing system: Oil fire burner with auto cutoff with temp.

- Insulation: 75mm thick mineral wool insulation with SS inside

- Max. capacity: 2000 ltr.

- Suitable for: 2000 ltr. x 1 no. or 1500 ltr. x 1 no.

Operating parameters:

- Power requirement: 6 HP (415 volt 3 phase)

- Process temperature: 210 degree

- Manpower: 2 semi skilled persons

- Heating time: 30 mins.

- Cooling time: 20 mins.

- Loading unloading time: 20 mins.

- Total cycle time: 70 mins.

- Fuel: High speed diesel

- Fuel requirement: 5 ltr. / cycle

- Fuel for any size of tank: 5 ltr. / tank

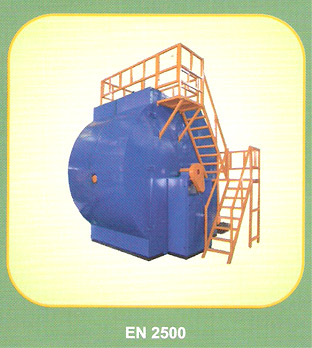

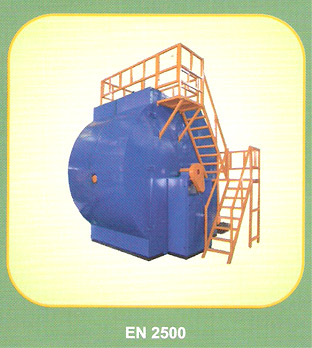

5) EN 2500

- Control panel: AC motor with AC drive

- Firing system: Oil fire burner with auto cutoff with temp.

- Insulation: 75mm thick mineral wool insulation with SS inside

- Max. capacity: 2500 ltr.

- Suitable for: 2500 ltr. x 1 no. or 2000 ltr. x 1 no. or 1500 ltr. x 1 no. or 1000 ltr. x 1 no.

Operating parameters:

- Power requirement: 6 HP (415 volt 3 phase)

- Process temperature: 210 degree

- Manpower: 2 semi skilled persons

- Heating time: 30 mins.

- Cooling time: 20 mins.

- Loading unloading time: 20 mins.

- Total cycle time: 70 mins.

- Fuel: High speed diesel

- Fuel for any size of tank: 5.5 ltr. / tank

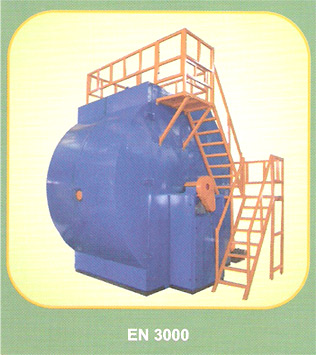

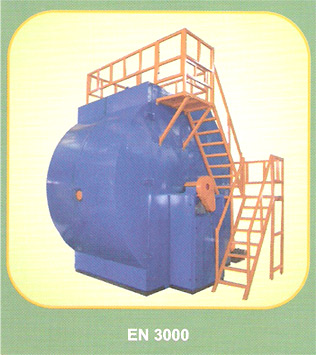

6) EN 3000

- Control panel: AC motor with AC drive

- Firing system: Oil fire burner with auto cutoff with temp.

- Insulation: 75mm thick mineral wool insulation with SS inside

- Max. capacity: 3000 ltr.

- Suitable for: 3000 ltr. x 1 no. or 2000 ltr. x 1 no. or 1500 ltr. x 1 no.

Operating parameters:

- Power requirement: 7 HP (415 volt 3 phase)

- Process temperature: 210 degree

- Manpower: 2 semi skilled persons

- Heating time: 30 mins.

- Cooling time: 25 mins.

- Loading unloading time: 20 mins.

- Total cycle time: 75 mins.

- Fuel: High speed diesel

- Fuel requirement: 6 ltr. / cycle

- Fuel for any size of tank: 6 ltr. / tank

(For more details and images, please see next pages)

For More Details Contact:

Vinodrai Engineers Pvt. Ltd.

www.vinodrai.com

Mr. Sunil Raithatha

Tel.: +91-2482 262000, 262400

Mobile: +91-9890260111

E-mail: vinodraieng@rediffmail.com, sunil@vinodrai.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}