For Sale - PCM - 3236 - Clamshell Machines

Reference Numbers

PCM - 3236Product

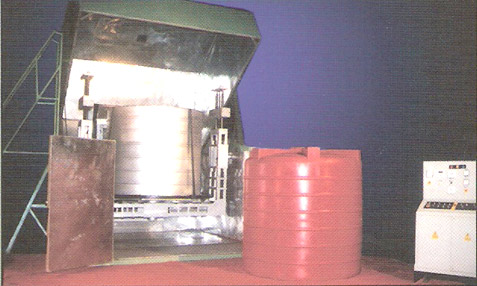

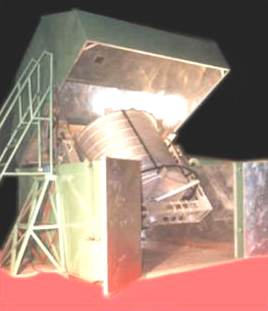

Clamshell Machines

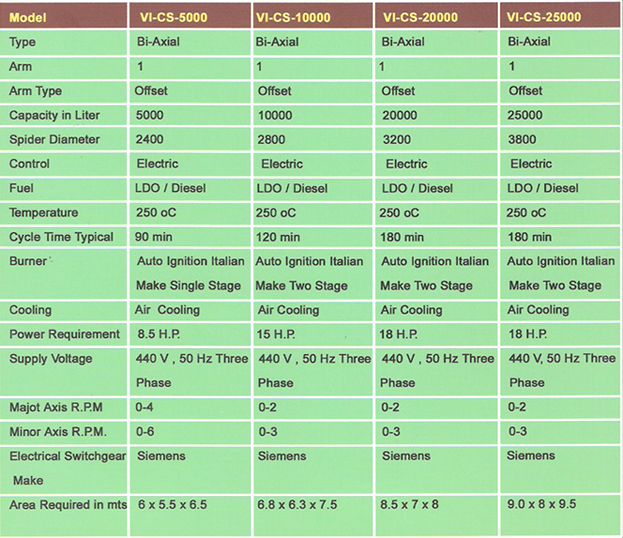

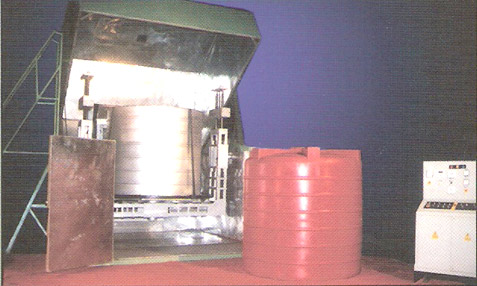

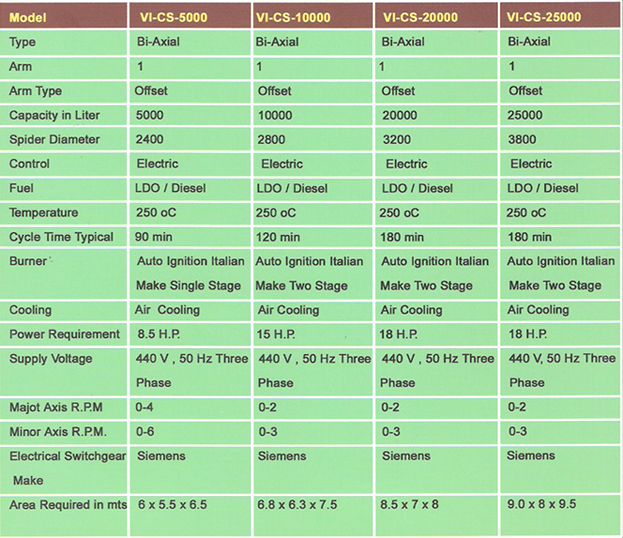

Clamshell ranges of machines are most suited for production of large tanks. Clamshell is a single station bi-axial rotational moulding machine with single U arm. U arm is heavy duty and supported from both side by bearing housings. There are four model available in this range with capacity to mount 5000, 10000, 20000 and 25000 lit. vertical moulds.

Comparison between Clamshell and Rock-N-Roll Machines:

Vinodrai introduces Clamshell machine for manufacturing high capacity rotational moulded tanks. Traditionally Rock-N-Roll types of machines were most popular way of producing large tanks. Rock-N-Roll machines are low cost simple open flame machines most suited for low volume of production. Many disadvantages inherent with these machines resulted in poor quality of the product and higher reject rates.

Following are few disadvantages of Rock-N-Roll machine.

- Open fire heating temperature control difficult.

- Process is operator dependent. So unpredictable quality.

- As machine is not truly bi-axial rotation, wall thickness variations is high resulting in higher material consumption.

- High value addition products like double, triple and foam layer tanks difficult to produce.

- Machine not suitable to produce tanks other than round shape.

- Labor cost is high as only skilled operator can produce tank with out rejection.

- Higher fuel and electric energy cost.

- Reject rates are high.

- Harsh working environment, operators are exposed to open flame heat and smoke.

Engineers at Vinodrai took up the challenge to develop first Clamshell machine in India. Our main aim was to remove all disadvantages of Rock-N-Roll machines. Years of development and commitment toward this goal resulted in refined, technologically advanced Clamshell range of machine.

Main advantages of Clamshell range of machine is as follows.

- Totally Bi-Axial machine.

- Closed oven with forced air circulation for uniform heating of mould.

- Fuel efficient Italian package burner with auto ignition.

- Temperature, RPM and cycle time controlled by advance control panel.

- Designed to produce double layer, triple layer and insulated tanks.

- User friendly machine, even unskilled operator can run the machine. Low manpower cost.

- Capable for producing tanks in less material because of even distribution of material.

- No in process rejection.

- Low fuel and electric energy cost.

- Clean working environment.

(For more details and images, please see next pages)

For More Details Contact:

Vinodrai Engineers Pvt. Ltd.

www.vinodrai.com

Mr. Sunil Raithatha

Tel.: +91-2482 262000, 262400

Mobile: +91-9890260111

E-mail: vinodraieng@rediffmail.com, sunil@vinodrai.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}