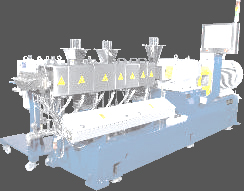

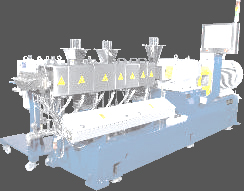

For Sale - PCM - 3339 - Alpha S Class Exturder

Reference Numbers

PCM - 3339Product

Alpha S Class Exturder

Steer's Alpha S Class extruders are best suited for shear intensive application with high bulk density ingredients and specific energy of 0.2 KWH / kg or higher.

Features:

1) Transmission Section:

- Main drive: Modern microprocessor based vector controlled variable speed drive with

torque control.

- Gear box: Engineered for long-life at ultra high torque capacity of 17Nm/cm.

2) Processing Section:

- Materials: Highest grades of tool-steel with high wear and corrosion resistance.

- Treatment: Steer also employs in-house heat treatment and surface engineering facility. Steer has in-house capability to conduct wear and corrosion tests and mechanical properties tests apart from sophisticated chemical characterization.

- Manufacturing: Use of advanced CAD/CAM with 100 percent machining on CNC.

- Geometry: The entire Extruder Processing Zone (EPZ) is based on the modular design concept. All the barrels can be die-assembled by means of the special quick clamp system. The screw shafts have been designed with split construction comprising of a safety shaft and adaptor and the Continua splined shaft. Continua spline (Patent pending) avoids stress concentration in both screw shafts and screw elements, thereby increasing torque carrying capacity.

Steer's patented Fractional Lobed Blocks are used for processing difficult materials. The Kneading blocks have multiple lobe geometry which is effective in creating uniform shear, hence intensifying the shearing effect.

Applications:

- Colour masterbatches

- Alloys and Blends (For picture, please see next page)

For More Details Contact:

Steer Engineering Pvt. Ltd.

www.steerworld.com

Mr.Sanjay K Shah

Director (Marketing)

Tel: +91-80-23723310 extension 42

Mobile: +919845806642

E-mail: sanjay.shah@steerworld.com, manjunath.madhugiri@steerworld.com, satish@steerworld.com, drbabu@steerworld.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}