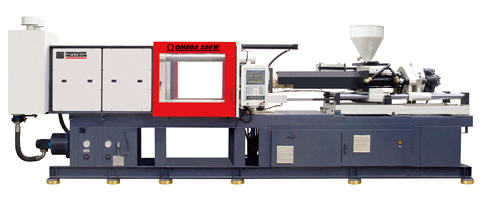

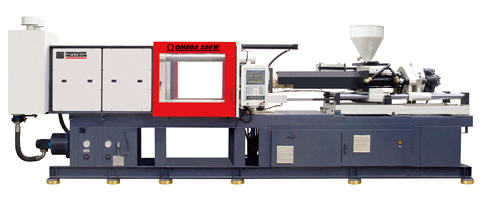

For Sale - PCM - 3467 - Ferromatik 80 ton to 910 ton Hydraulic Injection Moulding Machine

Reference Numbers

PCM - 3467Product

Ferromatik 80 ton to 910 ton Hydraulic Injection Moulding Machine

Ferromatik offers hydraulic injection moulding machines ranging from 80 to 910 ton

Main Features:

- Generous specification

- Centrally distributed force across platen

- High productivity

- User friendly control

Machines widely used in

- Furniture

- Consumer goods

- House ware

- Rigid packaging

- Automotive

- Industrial products

Clamp

- Hollow headless RAM with mono seal and no piston rings

- Large prefill designed for fast tonnage build-up

- Rapid traverse cylinders

- Conical strain rod nuts and controlled stress on tie rods

- Adjustable moving platen skates

- Rigid cast platens with FEA

- Adjustable pressure setting of closing and opening stage

- Proportional speed control with 5 closing and 5 opening speed

- Adjustable 2 stage mould safety pressure and 1 stage speed

- Position based ramping for accurate position switching - precise speed and pressure control

- Linear position transducer for accurate clamp position control

- Sensitive mould protection with try again circuit

- Stage wise actual time display

- Insert moulding program

Ejector

- Knock-out bar

- 2 stage programmable ejector forward profile with soft eject

- Ejector speed and force adjustable on screen

- Linear transducer for ejector position

- Pulsating ejector strokes up to 9 pulses

- Intermediate retract set point

- Ejector stay forward and forward dwell timer

Injection

- 6 stage injection velocity and 15 stage injection pressure profile

- 5 stage screw speed and 5 stage back pressure control (setting) through screen

- Digital setting of extruder rpm and digital read out of actual rpm

- Wide choice of injection units with A-B-C screw / barrel combinations

- Easy injection unit swiveling

- Switch over from fill to pack based on position / time / pressure

- Linear position transducer for accurate injection position control

- Injection decompression before / after refilling or both

- Semi-auto purge, cold slug removal and intrusion moulding programs

- Aluminum chequered plate below purge area

- Sprue break with timer

- Injection start, suck-back and melt decompression - delay timer

- Graphically adjustable alarm bands for injection pressure

- Sliding hopper

Temperature Control:

- Actual current display of heating zones

- Heater failure and thermocouple failure detection

- Accurate PID temperature control settable on screen

- Feed throat temperature indication

- Auto heat startup and shutdown

- Heat standby after set number of cycles

- Soak timer for cold start protection

- High/low temperature alarm

- Set and actual temperature data with bar graph

Controls

- 22 parameter monitoring for last 150 cycles with graphics

- 10.4" TFT color display with alpha - numeric keypad

- Actual injection speed and pressure graph display with indication of high, low and average value

- 80 mould data storage

- Configurable multilevel password with operator's name

- Graphically presentation of hourly production

- Customized setup menu

- High / low limit display for each adjustable parameter

- I / O diagnosis - analog and digital

- Timer precision in 0.01 second

- Change log menu: logs last 100 set points changes with time and date

- Statistical process control (SPC) with graphics

- Process mode: Functions with its co-functions on a single key press

- Note pad and maintenance scheduling

- Freely programmable smart outputs

- Over view screen with graphical display of machine functions

- Soft keys for fast access of select menus

- Auto shut down

- Visual and audible alarm

- 1000 alarm history with date and time log

- Printer interface with USB port

Hydraulics:

- Multiple pump with PQ circuit

- Pump and motor slide out from base for ease of maintenance

- Ergonomic hydraulic layout for easy approach

- Valves placed near actuators for rapid response

- Pre-heating circuit for hydraulic oil

- Low oil level audible alarm and motor shut down

- Continuous oil filtration with 10 micron filter

- Audible alarm for filter clogging

Available Options:

- Air ejection

- Hydraulic core pull

- Feed throat temperature control

- PID oil temperature control

- Part drop detect for single cavity

- Water battery with temperature indicator

- Water manifolds

- Robot interface (SPI / Euromap)

- Extra heating zones

- Nozzle contact force by pressure switch

- Ejector on fly

- Jam bar

- T-slot platens

- Extended daylight with ram spacer

- Eject retract limit switch verification

- Insulated heater band

- Bimetallic barrel and hardened / coated screw

- AC variable frequency drive

- Special paint

(For picture, please see next page)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}