For Sale - PCM - 3474 - PE Tube Making Plant

Reference Numbers

PCM - 3474Product

PE Tube Making Plant

We are a leading supplier of PE squeeze tube plant. We have exports to over 30 countries and offer a range of reliable models

We can offer complete line or individual machines in various models and with additional options. A typical complete Tube making line consists of the following.

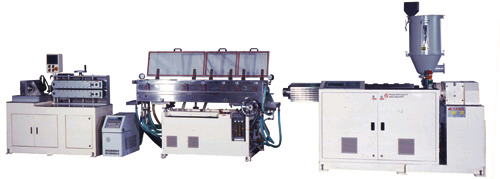

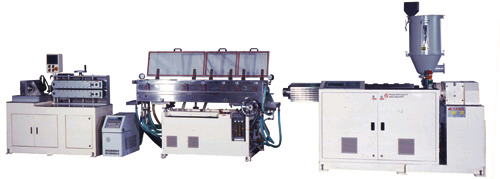

1A) Extruder Mono Layer

Features:

- Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials.

- For years of research and development, our remarkable achievements on LLDPE & LDPE melting, screw design, device of die head, material adoption, and surface treatment, together with size control by figuration and length restraint by servo motor have produced valuable and high-quality tubes.

Main Specifications:

- Screw Dia: 50 mm

- Screw L/D Ratio: 30/1

- Screw Type: Full Flight

- Main Motor: 20 HP with Inverter

- Heater: 17.5 kw, 7 Section Control

- Water consumption: 30 L/min, 5~10?

- Power consumption: 58.5 kw

- Extrusion Linear Speed: 8 m/min

a. Medium Speed: 8 m/min (EDC-08-01)

b. High Speed: 16 m/min (EDC-16-01)

- Cutting Speed:

a. Medium Speed: 100 pcs/min (EDC-08-01)

b. High Speed: 160 pcs/min (EDC-16-1)

- Tube Dia Range: 19~60 mm

- Machine Size: 6000x 1200x 1800 mm

- Total Net Weight: approx. 2250 kg

- Optional Device: Laser Measuring Head is available for all types of our extruders. It helps the user to control the tube diameter and gives high quality tubes to the customers.

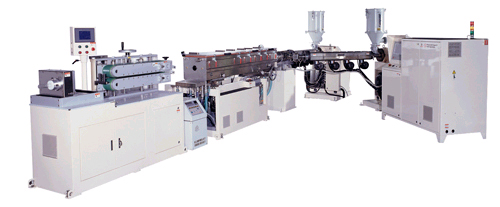

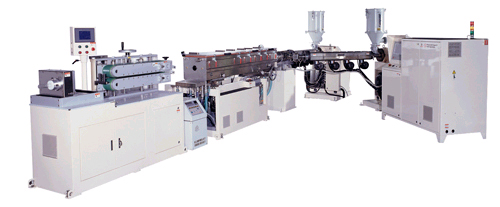

1B) Extruder Two Layer

Features:

- Two-layer extrusion tube can reduce material cost. (Using: Pearl + PE/PE + Pigment)

- The temperature controllers of different materials can be controlled individually. In this way, we can find out the best running condition on the materials both in running fluency and dissolubility.

- The surface of co-extrusion tubes made by two-layer machine is more glossy than the surface of mono-layer tubes.

- Using the same material on two-layer same material on two-layer co-extrusion can increase the water-resistance and anti-penetration of the materials for about 20~30 percent (Using: PE + Pigment. Inner: recycled material.)

Main specifications:

- Screw Dia (inner): Diameter45mm.15HP

- Screw Dia (Outer): Diameter 40mm.10HP

- Screw L/D Ratio (inner): 32/1

- Screw L/D Ratio (outer): 32/1

- Screw Type: Full flight

- Water consumption: 40L/min. 5~10 Degree C

- Power consumption: 66kw

- Extrusion Linear Speed: 8m/min

- Cutting Speed: 100pcs/min

- Tube Dia Range: Diameter 19~60mm

- Machine size: 6500 x 4000 x 2100mm

- Total Net Weight: approx. 3240kg

- Optional Device: Laser Measuring Head is available for all types of our extruders. It helps the user to control the tube diameter and gives high quality tubes to the customers.

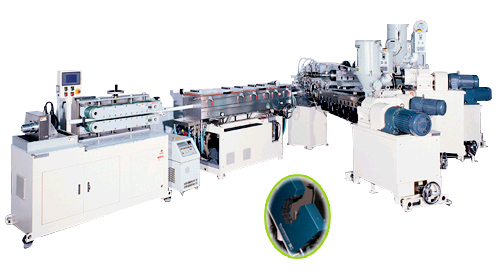

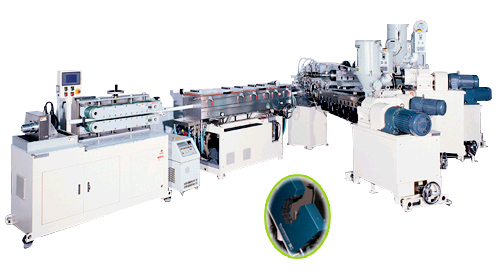

1C) Multilayer Extruder

The Features of Co-Extrusion Tube:

Plastic material has its own characters. In co-extrusion system, we use and combine several kinds of materials. Therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube.

- Glossy surface (using: EVOH/Resin/PE)

- Extensive color combination (using: PE+PEARL/PE+PIGMENT)

- Excellent barrier property (using: PE/TIE RESIN/EVOH/TIE RESIN/PE)

- Scratch and dust free (using: LDPE/LDPE/LLDPE)

Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic etc.

Main Specifications:

- Screw Dia (inner): 45mm. L/D: 32/1

- Screw Dia (resin): 35mm. L/D: 30/1

- Screw Dia (EVOH): 30mm. L/D: 25/1

- Screw Dia (outer): 40mm. L/D: 32/1

- Screw Type: Full Flight

- Motor: 15HP x 1, 10HP x 1, 5.5HP x 2

- Water Consumption: 350 L/min

- Power Consumption: 95.6kw

- Extrusion Linear Speed: 8m/min (50mm)

- Cutting Speed: 100pcs/min

- Tube Dia Range: Diameter 19~60mm

- Machine Size: (L) 7,000 x (W) 3,500 x (H) 2,300mm

- Total New Weight: approx. 5200 kg

- Optional Device: Laser Measuring Head is available for all types of our extruders. It helps the user to control the tube diameter and gives high quality tubes to the customers.

2) Heading Machine

Features:

- With 47 sets memory storage in the computer and the monitor which can show the operating status.

- Insert tubes manually and remove tubes with air blowing unit.

- Double heading mould for fast running.

- Our some models are with hot runner and there won't be any waste left after production which can save cost.

- Our some models are without hot runner and take out the waste by air blowing automatically and safely

Main specifications:

- Screw Dia: 36 mm

- Shot Weight: 159 g

- Nozzle Retraction Stroke: 230 mm

- Number of Temperature Control: 3 sections

- Hopper Volume: 30kgs

- Clamping Force: 55ton

- Tie Bar Distance: 500 x 340mm

- Slide Stroke: 500mm

- Hydraulic Pressure: 140kg/cm3

- Oil Reservoir Capacity: 150L

- Water Consumption: 800L/hr

- Power Consumption: 15 kw (With Hot runner),10 kw (Without Hot runner)

- Air Consumption: 320L/min

- Heading Range: 19~60 Diameter mm

- Heading Speed:

a. 25~30pcs/min (W/Hot runner)

b. 20~25pcs/min (W/Hot runner)

- Machine size: 3100x1500x3500mm

- Total Net Weight: approx. 2300 kg

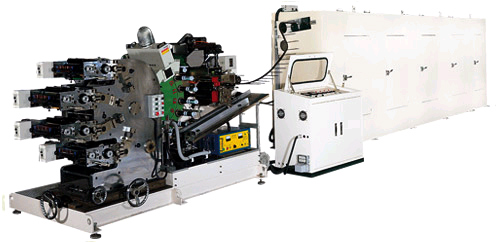

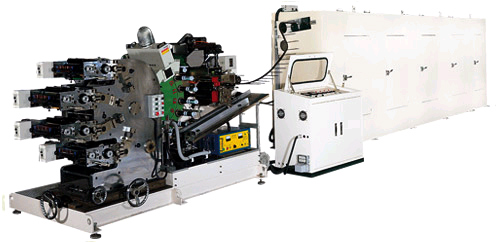

3) Printing

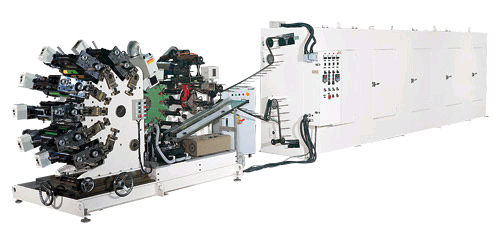

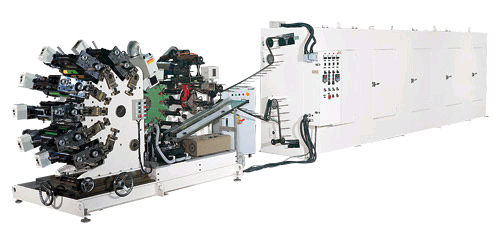

a) Computerized 4 Color Printing, Coating & Drying Machine

Features:

- Ink Unit Motor: 5HP.with Inverter

- Mandrel Unit Motor: 3HP

- Oven Motor: 3HP

- Ink Adjust Motor: 150 w x 4pcs

- Printing Ink: UV Ink

- Printing Plate: Copper Zinc Polymer

- UV Dryer Capacity: 5 kw (180 w/cm2 )

- Printing Dia: 19 to 60 mm

- Printing Length: 200 mm (Max)

- Printing Speed: 60 to 80 pcs/min

- Air Consumption: 150 L/min

- Power Consumption: 55 kw

- Pin No. in Oven: 1100 pcs (10 Meter Oven)

- Machine Size: 15000 x 1500 x 2000 mm

- Total Net Weight: approx. 6450 kg

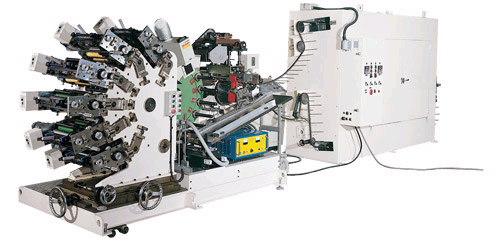

b) Computerized 6 Color Printing, Coating & Drying Machine

Features:

- Computerized 4~6 color printing, coating and drying machine is based on advanced technical design of European countries. Being the best choice for PE tube printing, our machines have stable quality and are easy to operate and maintain.

- There are individual motors for printing blanket unit, mandrel disk unit and oven, and the speed of above mechanism can coordinate with each other by the control of computer, coating and drying separately or synchronously. It's a very good choice for a new user. Besides, it is the most suitable for precise and clear printing. Larger area printing & half time printing's also available on this model.

- We offer Regular Oven (heater type), UV Oven, and two in one oven for customer's choice.

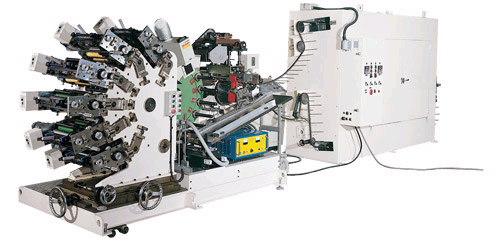

c) Computerized 6 Color Printing, Coating & Drying Machine

For UV lacquer, special UV oven is required, which is equipped with rapid drying mechanism to produce tubes with glossier surface. We also offer UV & heater oven, which can save electricity and without space-limit. Customers can choose either of them accordingly.

- Precise index ensures accuracy of every movement.

- Tube feeding system works with detector. Coating mechanism will not move without tubes on mandrels.

- Equipped with precipitator. Corona system can keep tube clean before printing.

- With optional sleeve printing mechanism tubes are headed directly after printing. No double-heading or double cutting procedures and save material. Vastly used on printing different shape of tubes.

Well-devised Ink-transmission system runs well. Especially in broad area printing and screen printing. Foldable ink unit is easy to clean. Change color and printing plate.

d) Computerized 6 Color Printing, Coating & Drying Machine

Features:

- For left oven design, there's no space limit, which benefits tube withdrawing and in-line connection in the future.

- Transferring tubes automatically can lower blowing noise.

- This model is equipped with an extra device-sleeve printing without shoulder, and customers can choose either function when printing and save cost.

- Ink transferring is controlled by individual motor. Ink supply and transferring speed are more stable and accurate under the control of speed controller.

- No tube, no coating.

- Printing, Coating and drying functions of this machine can be operated separately or synchronously.

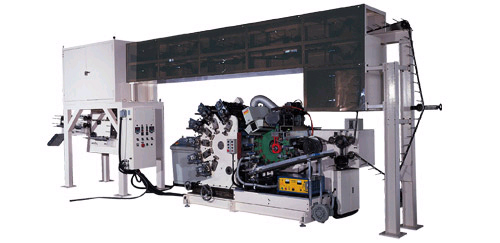

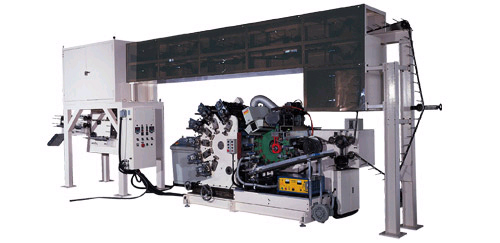

e) Computerized 6 Color Printing, Coating & Drying Machine

Features

- Monitor screen for easy operation.

- New ink-feeding system is more convenient and can speed up the production.

- Additional plate-adjusting motor can move the plate little by little.

- Plate-adjusting mechanism outside the inking system can adjust the plate during operation.

- Tube withdrawing in pairs can reduce punching on machine and extend machine's running life.

- Advance roller moves in turbinate style to balance the printing pressure and increase the stability.

- Individual ink roller motor can control in capacity.

- No tubes on printing mandrel, no printing and coating.

- Being controlled by one motor makes the machine operates specifically. The printing wheel, turning plate and chain can be operated individually.

- Coating system is set under the printing mandrel, to avoid the vanish dripping on mandrels for maintaining and cleaning the machine easily.

- The rapid moving mechanism can remove the machine and leave 200mm space for maintenance and cleaning.

4) Drilling, Al Foil Sealing and capping

Features:

- There are three functions in this machine, and you can operate them individually or synchronously.

- With additional conveyor for feeding tubes automatically.

- No tube. No sealing and capping.

Main specifications:

- Main Motor: 1PH

- Suction Motor: 1/2 HP

- Drilling Speed: 60 pcs/min

- Drilling Dia Range: Diameter 3~12 mm

- Foiling Dia Range: Diameter 8~20 mm

- Foiling Speed: 60 pcs/min

- Tube Dia Range: Diameter 19~60 mm

- Tube Length: Diameter 50~200 mm

- Air Consumption: 210 L/min

- Power Consumption: 6.6 kw

- Conveyer Motor: 200 w

- Machine Size: 4,200 x 1,700 x 2,300 mm

- Capping Speed: 60 pcs/min

- Total Net Weight: approx. 1,190 kg

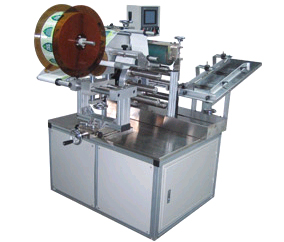

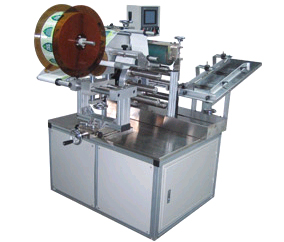

5) Labeling Machine

Features:

- Registered & Non-Registered labeling on single side.

- Registered & Non-Registered labeling on both sides.

- Automatic tube feeding board.

- Automatic tube unloading by blowing system.

- Auto-detective sensor for no tube, no labeling.

Main Specifications:

- Main Motor: 1 HP

- Labeling Speed: 30~50 pcs/min

- Tube Die: Diameter 19~60mm

- Tube Length: 50~220mm

- Air Consumption: 3~5 kg/cm2

6) Hot Stamping Machine

Main Specifications:

- Stamping Dia: Diameter 19~50mm

- Stamping Length: 3~120mm

- Stamping Speed: 5~10pcs/min

- Heater: 1.5 kw

- Air Consumption: 50 L/min

- Power Consumption: 1.6kw

- Machine Size: 1250 x 600 x 1500mm

- Total Net Weight: approx. 190kg

(For images, please see next pages)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}