For Sale - PCM - 3540 - All-Electric EcoPower Series Injection Moulding Machines (55 to 300 tons)

Reference Numbers

PCM - 3540Product

All-Electric EcoPower Series Injection Moulding Machines (55 to 300 tons)

The production of all-electric injection molding machines has a long tradition at Battenfeld. With the new EcoPower machine series, Wittmann Battenfeld demonstrates its more than 20 years of expertise in the construction of all-electric injection molding machines. This fourth generation is now setting new benchmarks in user-friendliness and precision. It also offers enormous energy-saving potential. The all-electric EcoPower, with clamping forces ranging from 55 to 300 tons, combines efficiency with precision. The beltless EcoPower scores with a compact injection unit and the clean design of its clamping unit, together with a highly efficient direct drive. The machine also offers a small footprint and is open at the top and on the injection side.

Clamping unit:

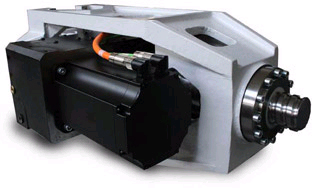

The precise, efficient direct toggle drive stands out by its high dynamics and positioning accuracy. It is also extremely energy-efficient.

The toggle encasements are sealed on the outside to ensure a clean clamping unit suitable for clean room applications as standard. Starting the injection process parallel to clamping force build-up is also possible in the standard version, leading to a gain in cycle time.

A speed-controlled servo-hydraulic drive is used in the standard version, which features a hydraulic ejector, a hydraulic nozzle stroke and an optional core pull. All-electric drives for these functions are available as an option.

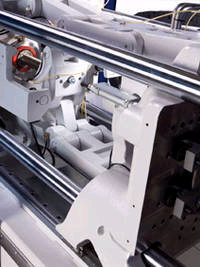

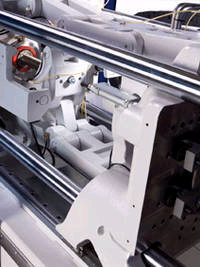

The moving platen is supported by smooth running linear guides. The hard chrome plated tie-bars are released, which prevents the formation of lubricant deposits in the mold space. The smoothness of the linear guides favors optimal mold protection.

The safety gate, open at the top, is flexible enough to accommodate automation equipment, and easy to clean. The swivel-mounted touch screen of the machine's control system is positioned ergonomically and can be moved to the most convenient working position, which also allows easy access to the nozzle area.

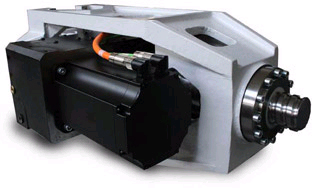

Injection unit:

The injection unit is laid out for high-speed and high-precision injection processes even under maximum injection pressure. The encapsulated drive is clean and compact. Injection and metering are effected via a dual drive with a circulating ball spindle at its center. The EcoPower comes with air cooling as standard and two extension options: water cooling with either an open or a closed cooling circuit.

The barrel can be completely removed from above. It can also be held in an intermediate position, from which the screw can be quickly removed to the rear for easy maintenance. The use of existing barrels from the HM and TM series is also possible.

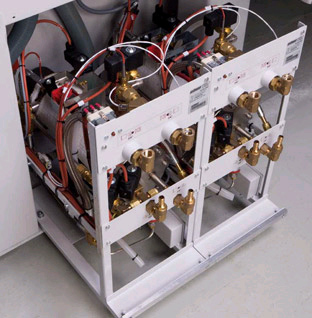

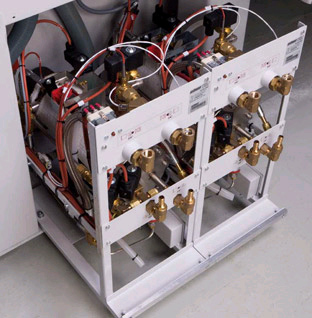

Peripheral equipment from Wittmann built into the machine frame helps to substantially reduce the machine's space requirements. The entire peripheral equipment can also be operated, visualized and its data stored directly via the machine's Unilog B6 control system.

(For images, please see next pages)

For More Details Contact:

Wittmann Battenfeld India Pvt. Ltd.

Mr. Nandakumar T.

Tel.: +91-44-42077009

Mobile: +919884909911

E-mail: nanda.kumar@wittmann-group.com

Web: http://www.wittmann-group.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}