For Sale - PCM - 3548 - Laboratory Mixer

Reference Numbers

PCM - 3548Product

Laboratory Mixer

A Radhekrishna Extrusions has introduced laboratory mixers with latest technologies for various applications and testing of R & D Labs.

Salient Features of Laboratory Mixer:

- Stainless steel jacketed mixing vessel with 5 liter and 10 liter capacity. Mixing vessel is corrosion resistance and inside jacket made from SS-304 and gloss polished.

- The bottom curvature of vessel gives VORTEX formation, which results into homogeneous and free flowing dry blends.

- The mixing tool is made of SS-304 with wear resistant coating.

- The mixing tool driven by AC Motor controlled by AC variable frequency drive.

- The tool speed can be varied as per process requirement.

- Flow deflector is provided from the lid for optimum setting of mixing process.

- Specially design pneumaseal system at the bottom portion of vessel to avoid material infiltration to bearing.

- The control panel is consists of programmable controls. The panel is attached with main machine frame to ease of operation.

- Lightweight, sturdy and portable base frame mounted on four self-locking caster wheel.

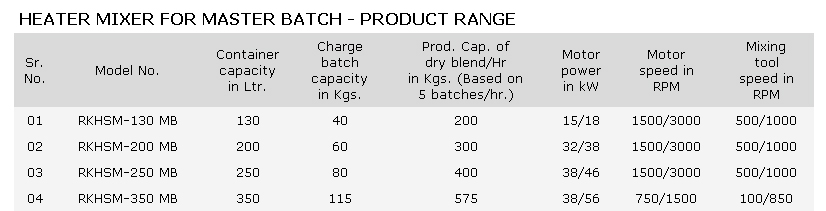

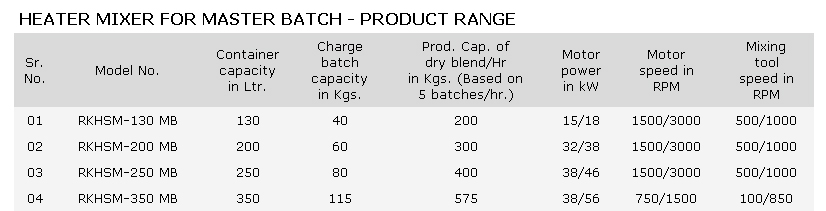

Master batch mixer:

The master batch mixers are made by using state-of-the-art technologies to fulfill the specific need of master batch processors.

Salient Features of Master Batch Mixer

1) Stainless steel mixing vessel

- Corrosion resistance and abrasion resistance

2) Vessel and discharge plate high gloss polished on the inside; discharge plate matches bottom dish

- No deposits, crusts or pockets of colour

- Rapid and complete discharge of the mixed material

- Easy and perfect cleaning

3) Mixing tools (type and profile) specifically developed for heat sensitive mixtures, such as, for example, master batch

- Made from stainless steel, thoroughly hardened and buffed

- Homogeneous mixtures

- Perfect dispersion of the components

- Granular, pourable, dust-free and product

- Short mixing times, high throughputs

4) Pneumaseal housing design

- Avoids material infiltration to bearings

5) Freely programmable controls

- Optimum adaptability to process technology requirement

(For more details and images, please see next pages)

For More Details Contact:

Shree Radhekrishna Extrusions Pvt. Ltd.

Mr. R. B. Patel, Mr. Tejas Patel

Tel.: +91-79- 25842509, 25841785

Mobile: +919824073240 (Mr. R. B. Patel) / +919824410997 (Mr. Tejas Patel)

E-mail: srke_co@yahoo.co.in, mail@radhekrishnaexports.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}