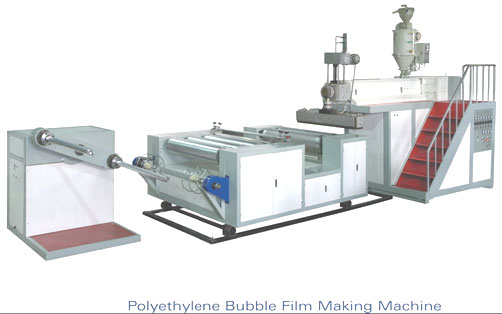

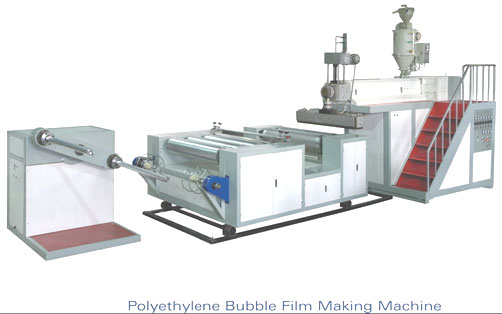

For Sale - PCM - 3955 - Air Bubble Film Machine Line

Reference Numbers

PCM - 3955Product

Air Bubble Film Machine Line

Model: JDPE-1000

- 1-layer structure: Single screw

- Useful width: 1000 mm

- Max. Capacity: 40Kg/hr - 50 kg/hr

- Main extruder: 1pc

- Filter change part: 1pc

- T-die: 1pc

- Traction part: 1 set

- Air bubble roller: 3pcs

- Side cutting part: 1set

- Rewing part: 1 set

- Electric control cabinet: 1set

a) Main extruder 01 set:

- Screw diameter:65 mm

- Screw production place: Zhoushan, Zhejiang

- Driving motor power:15kw

- Motor production place: Shanghai

- Speed ajustment: frequency conversion

- Heating power: 8 kw

- Heating way: aluminum-casted heating

- Temp-control way: automatic temperature control

b) Filter changer part:

- Filter change way: automatic motor change

- Driving power: 1.1 kw

c) T- die:

- Sheet amount: Two sheets

- Design of head: Cloth hanger

- Width: 1020 mm

- Heating area: 3 sections, Digital temperature (China)

- Heating power: 15.0 kw

- Heating way: Aluminium-casted heater

d) Traction Part:

- Flat roller diameter: 200 mm

- Flat roller material: Steel with chromium

- Flat roller amount: 2 pieces

- Slid roller diameter: 60mm

- Slid roller amount: 2 pieces

e) Bubble roller 1pc:

- Width:1020 mm

- Molding way: Volume minus pressure molding

- Cooling way: Water

- Speed adjustment: Frequency conversion

- Drive power: 2.2 kw

- Bubble specification: diameter 10 × 3.4 mm

f) Side cutting part:

- Cutting way: Knife cutting

- Cutting knife: 2pcs

- Cutting edge width: Adjustable

g) Rewinding part:

- Way:Manual

- Service position: Double

- Motor:Moment electrical motor

- Power:1.1 kw

h) Electric control cabinet:

- Invertor: Eura

- Temperature controller: Huibang, Jiansu

- Contactor: Simens

- Other electric parts: Zhengtai

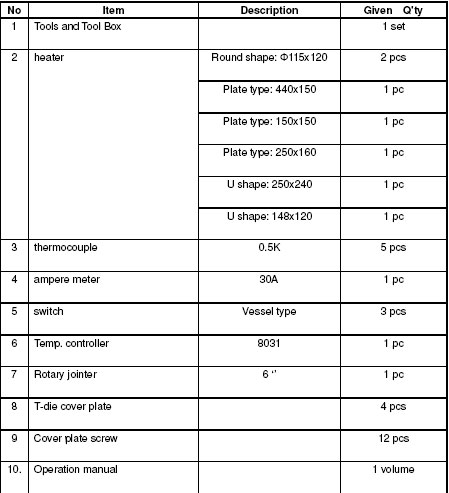

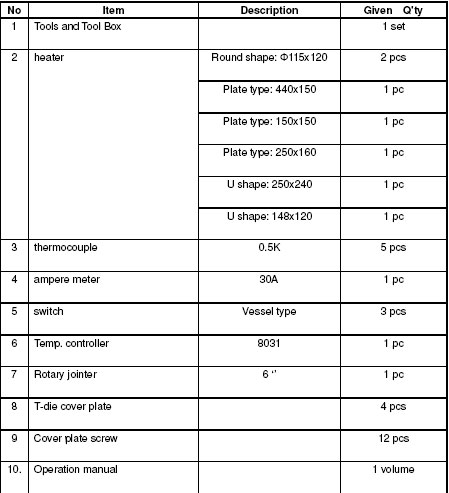

(For more details,and picture please see next pages)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}