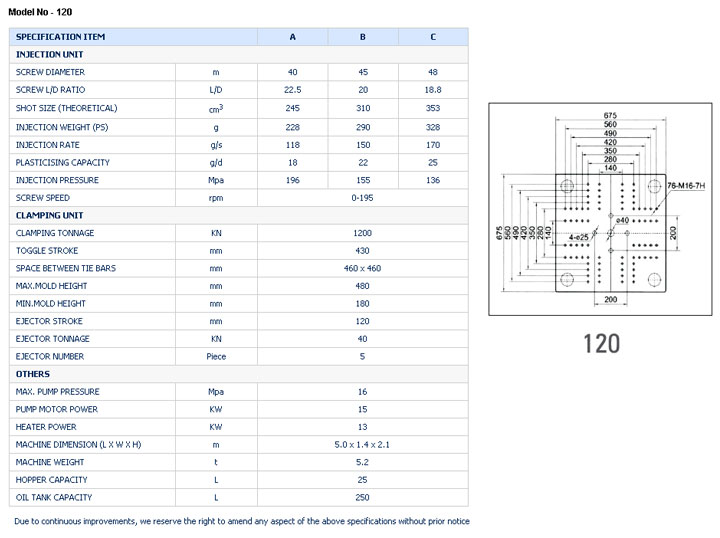

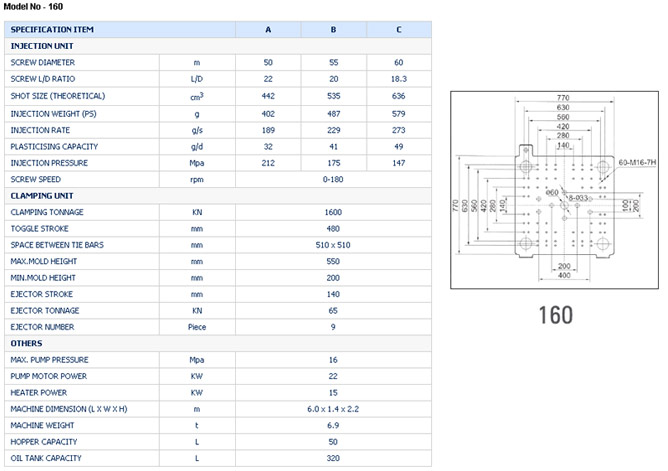

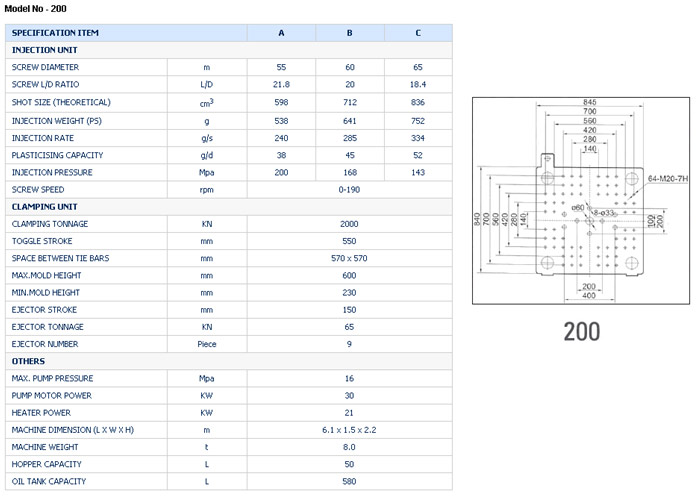

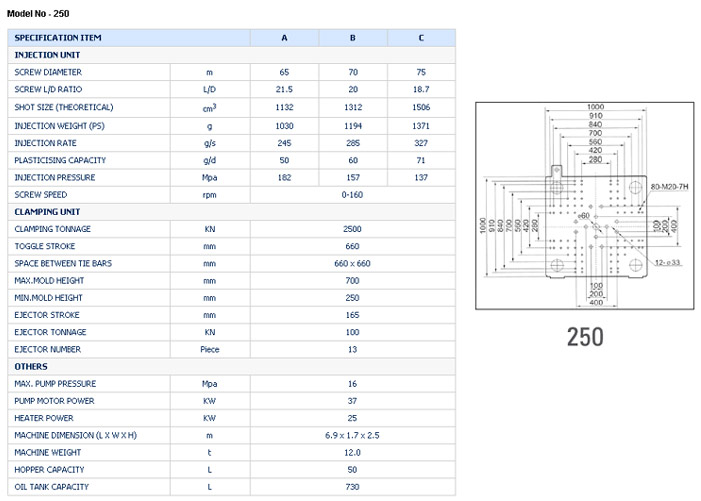

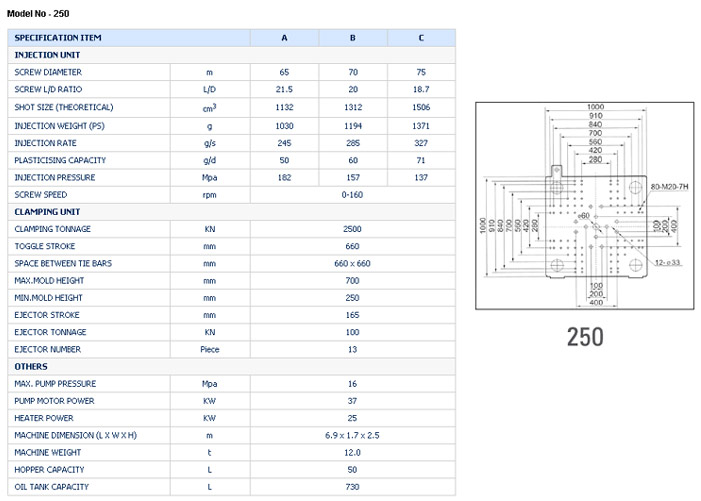

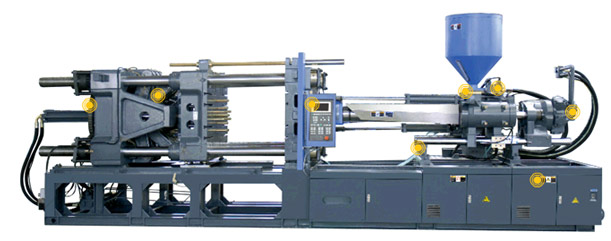

For Sale - PCM - 4000 - Magnum Injection Moulding Machines 120 to 250 Tons

Reference Numbers

PCM - 4000Product

Magnum Injection Moulding Machines 120 to 250 Tons

Magnum machine offers injection moulding machines 120 to 250 tons.

Controller:

- PLC with 8.4" COLOR LCD Screen with Alpha numeric keypad

- HMI with USB for data Restore and Back up function

- Password & Data Lock Key protected keypad to prevent tampering

- Fast Setting Page shows Bird Eye View of Machine Operation

- Short cut key to frequently used pages

- 100 Mould Data Storage

- Parameter monitoring for last 100 cycles

- Alarm alert, record and diagnostic function

- Temperature and Injection Graph monitors

Hydraulic system

- Proportional controlled pressure and speed setting from PLC

- Silent Hydraulic circuit

- High temperature & Low Oil level Alarm

- Return Line Filter with Clog Indicator

- European origin Oil Seals

- Hydraulic Core Pulling & unscrewing function (optional)

- External Oil cooler suited to Indian Condition

Clamping

- Optimized 5 point Toggle design for accuracy, smooth platen movement and equal distribution of clamping force

- 5 stage programmable Opening/closing speeds for ease of control

- Hydro motor assisted Mould Height Adjustment system

- Programmable Multi stage and pressure controlled Ejector system

- Four High tensile & Hard Chromed Tie Bars

- Hydraulic Cushion system for consistent Mould opening stroke.

- Linear Transducer for platen and ejector movement.

- Low Pressure Mould Safety

- Automated Lubrication system

Injection

- 6 stage Injection & Hold on function

- 3 stage Plasticizing/Charge Speed Control

- Auto PID adjust for barrel temperature

- High Plasticizing capacity Screw design

- Pre & Post charge Suck back function

- Cold Screw Protection

- Insulated Barrel Heater

- 5 Star radial Piston High torque Hydro motor

Machine Variants

Neo Series - Standard Machines

- Neo series machines come with all basic configurations, standard features and a Fixed Displacement pump.

- This machine is capable of performing all functions found in an Expensive Injection Moulding Machine

Neo Star Series - Machine with A.C. drive

- Neo Star series machine is a development on the NEO series and is fitted additionally with an A.C. Drive/Variable Frequency drive.

- The controller generates a analogue signal derived through a mathematical calculation between the set Pressure and Flow parameters to the Drive which controls the RPM of the Special Induction Motor based on function performed.

- There by bringing about saving in power consumed when compared to the Neo series.

- It is an inexpensive and maintenance free option compared to Variable Displacement pump which is not very suitable for Indian Shop floor condition.

Synergy - Servo Energy Saver Machine

- Synergy series machine offers the whole system of a synchronous rotary speed controlled servo motor with drive including a controller section.

- The drive takes the analogue signal of Pressure and Flow from the Machine controllers then a feedback loop is formed by the Drive controller taking the input signal from the Pressure transducer which then computes the resultant signal by measuring the deviations.

- This resultant signal drives the servo motor coupled with the fixed internal Gear pump.

- The RPM of the motor multiplied by displacement of the pump determines the output flow.

- Even the Internal Gear Pump has been optimized for variable speed, low leakage, low noise and high efficiency.

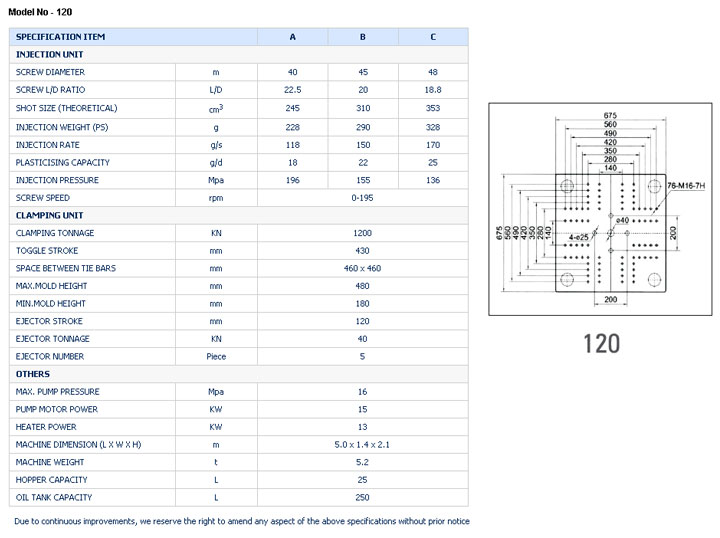

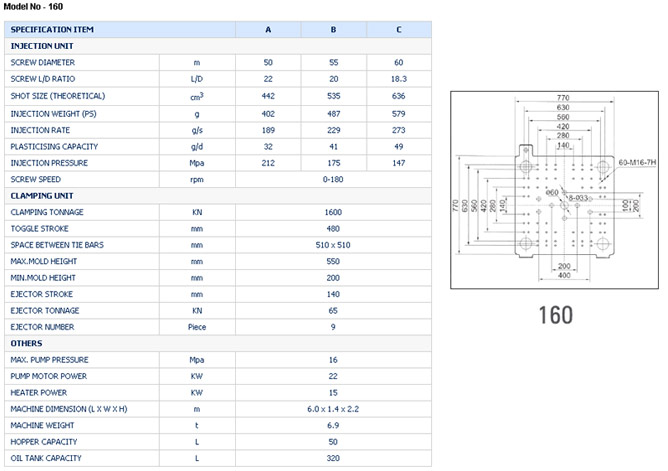

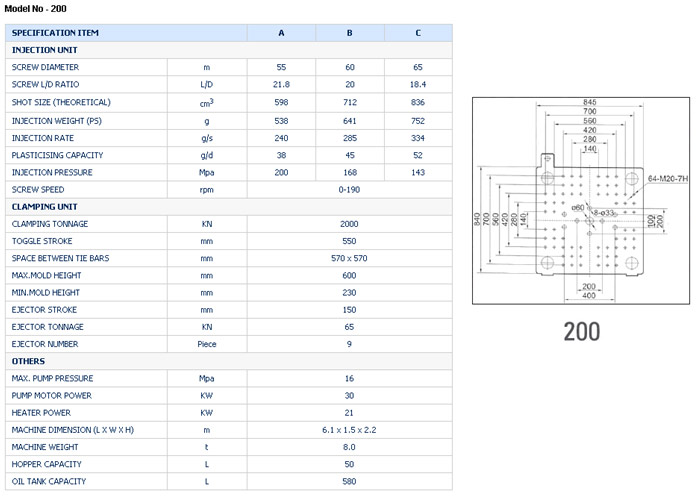

(For images, please see next pages)

For More Details Contact:

Magnum Machine & Tools Pvt. Ltd., Kolkata

Mr. Ankit Pansari, Mr. Devendra Surana

Mobile: +91-9830872006

Tel.:+91-33-2403 7963/64

Email: apansari@magnumgroup.in, dsurana@magnumgroup.in

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}