For Sale - PCM - 4091 - PET Bottle Washing And Granulating Line

Reference Numbers

PCM - 4091Product

PET Bottle Washing And Granulating Line

Raw material

- Post-consumer PET bottles

- Final product & Output capacity

- PET bottle flakes / 500 kg/hr

- Machine color

- Standard color: Blue and Yellow

Description of final product

- 1. Moisture: Max. 1-2%

- 2. Bulk density: 0.3G/CM3

- 3. Total impurity: 320 PPM

- A-Metal content: 20 PPM

- B-PE/PP content: 200 PPM

- 4. Particle size: 14-16 mm

(Can be designed as per special requirement)

Work condition (provide by customer)

Warehouse/Workshop

- Construction of foundations, construction works, earthworks and wall works

- Supply of cranes, fork-lifts or other lifting equipment

- Mounting materials and tools

- Dimension (M x M x M): 42 (L) × 10 (W) × 7 (H)

- About 500 square meters with height 7 meters

Power supply

- Supply voltage: 3 x 380 V + N + PE

- Voltage tolerance: +5%/-5%;

- Control voltage: 24VDC+220VAC

- Frequency: 50HZ+-2%

Wire/cables/water hose:

- Wires/cables:

- From power supply to control cabinet of this production line and all electrical cables from control cabinet to each machine;

Water hose:

- supply water to machines and pools;

Energy consumption

Installation power

- 154 KW (Actual power consumption percentage: 80%)

Water supply

- Consumption: 4 ton/hr (Proposed water-treatment project)

- Pressure: 0.4Mpa

Heat supply

- Temperature: 170 C

- Flow: 200 kg / hr

- Pressure: 0.7 MPA

Ancillary staff

- 6 Persons

1) Belt conveyor

- Waste bottle feeding Width of belt: 475 mm

- Basic material of belt: PVC

- Motor power: 1.5 KW

2) Trommel

- Removing rock, stone, dust, loosen caps and small metals, especially, the iron will be removed by high Strong Magnet.

- Screen sieve size: 50 mm

- Basis material: Galvanized carbon steel

- Frame: Carbon steel Diameter of barrel: 1000 mm, Length: 4000 mm

- Motor power: 3 KW Frequency inverter: Schneider

- Double chain roller, supporting roller is made of special nylon with graphite; twice size; With safe cover

3) Bottle label separator

- Removing labels from bottles

- Motor power: 7.5 KW

- Fan power: 3 KW

- Dimension: 4500 x 2500 x 3500 mm

- Principle: remove the labels by friction between screen and arms

- Remove 90-98% labels and 60% caps, decrease the pressure of downstream

4) Manual sorting belt

- Waste bottles conveying

- Width of belt: 475 mm

- Basic material of belt: PVC

- Motor power: 1.5 KW

- Metal detector can be provided as an option for removing metal from PET bottle

5) Crusher

- Bottle crushing

- Motor power: 37 KW

- Diameter of hole of screen sieve: 22 mm

- Screen sieve replacement: manual

- Cover opening: electric

- We can design the diameter of hole according to customer's requirement

- Qty. of rotary blades: 6 pc

- Qty. of stationary blades: 4 pc

- Basic material of blades: High-quality alloy Steel (SKD-11)

- Rotation speed of blade: 600 RPM

6) Screw loader

- PET flakes conveying

- Motor power: 2.2 KW

- Diameter of screw: 250 mm

- Part contact with raw materials: stainless steel

7) Floating washer

- Cleaning flakes and separating most dirt, labels and caps

- Motor power of screw loader: 4 KW

- Motor power of thumbwheel: 0.55 KW

- Quantity of thumbwheel: 3 Sets

- Tank dimension: 6719 mm (L) x 1106 mm (W) x 3044 mm (H)

- Diameter of screw: 219 mm

- Part contact with raw materials: stainless steel

8) Hot washer

- This device is connected with steam boiler.

- Steam is supplied into washing tank to heat water and flakes.

- Hot water makes dirt, label and glue water loosen from bottles.

- Meanwhile you need to add caustic soda and other cleaning chemicals into tank to clean bottle body.

- Motor power: 4 KW

- Dimension of hot chamber (Diameter × Height): 1.4 M × 2 M

- Volume of hot chamber?3.08 m3

- Part contact with raw materials: stainless steel

9) High-speed friction washer

- Get rid of glue water, dirty waste and oil

- Motor power: 15 KW

- Motor power of water pump: 1.5 KW

- Rotary speed of screw: 1200 Rpm

- Part contact with raw materials: stainless steel

10) Spray washer

- Spray washing (final washing)

- Motor power: 3 KW

- Diameter of screw: 196 mm

- Part contact with raw materials: stainless steel

11) Horizontal centrifugal dryer

- Dewatering

- Motor power: 11 KW

- Screw loader: 0.37 KW

- Rotary diameter: 406 mm

- Effect de-water length: 1 m

- Rotary speed of screw: 2600 rpm

- Part contact with raw materials: stainless steel

12) Pipeline dryer (optional)

- Hot air drying

- Heating power: 36 KW

- Power of blowing motor: 5.5 KW

- Power of suction motor: 4 KW

13) Label separator

- Removing little amount of label and dust in PET flakes

- Motor power of loading blower: 4 KW

- Part contact with raw materials: stainless steel

14) Packaging system

- Storage silo for PET flakes

- Motor power of loading blower: 4 KW

- Basic material of storage silo: stainless steel

- Dimension of silo: 3.5 M (H) × 1.2 M (Diameter)

- Part contact with raw materials: stainless steel

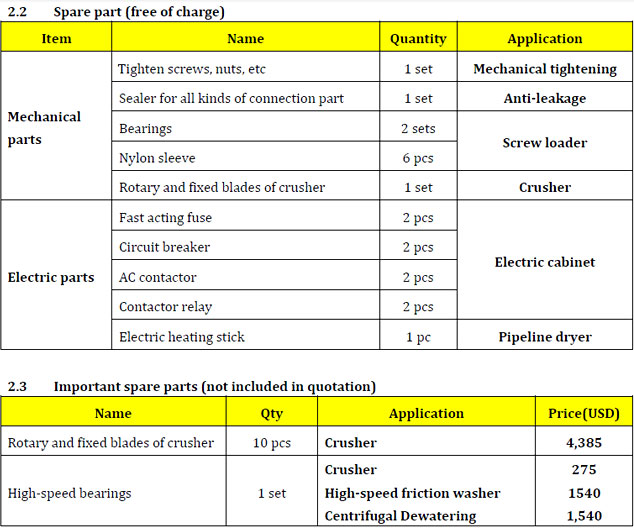

15) Electric cabinet

- Electric control system for washing line

- Touch screen: SIEMENS

- PLC control module: SIEMENS

- Electric control component: (Schneider), e.g. Circuit-breaker, AC contact, press button, pilot lamp

- This electric cabinet is used to control all machines in PET bottle washing line.

16) Steam boiler

- Supply steam air to hot washer

- Rated evaporation: 200 KG/H

- Rated working pressure: 0.7 Mpa

- Saturated steam temperature: 170 c

- Fuel consumption:

- Light diesel oil: 13 (Kg/hr)

- Natural gas:14 NM3 / hr

- Liquefied gas: 6 NM3 / hr

- Coal gas: 34 NM3 / hr

- Water supply caliber: 20 DN

- Main valve caliber: 32 DN

- Safety value caliber: 40 DN

- Sewage valve caliber: 25 DN

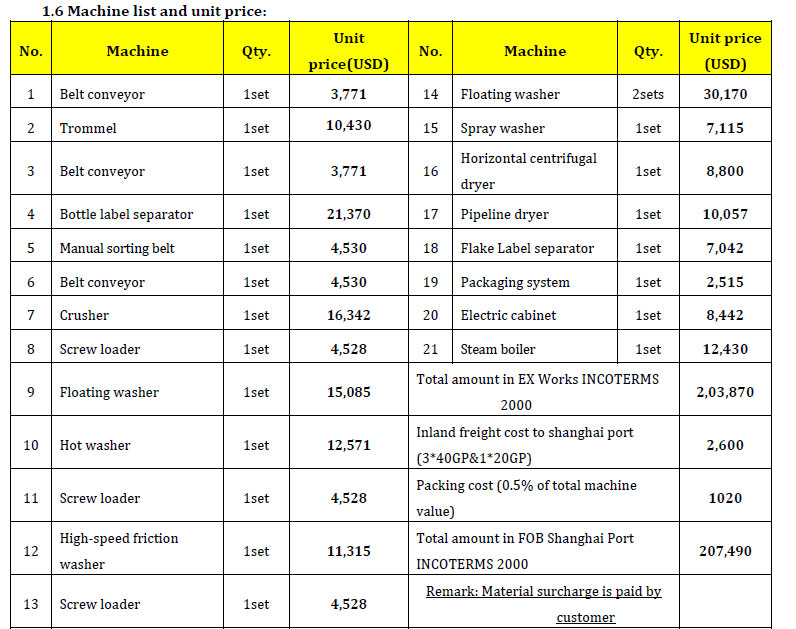

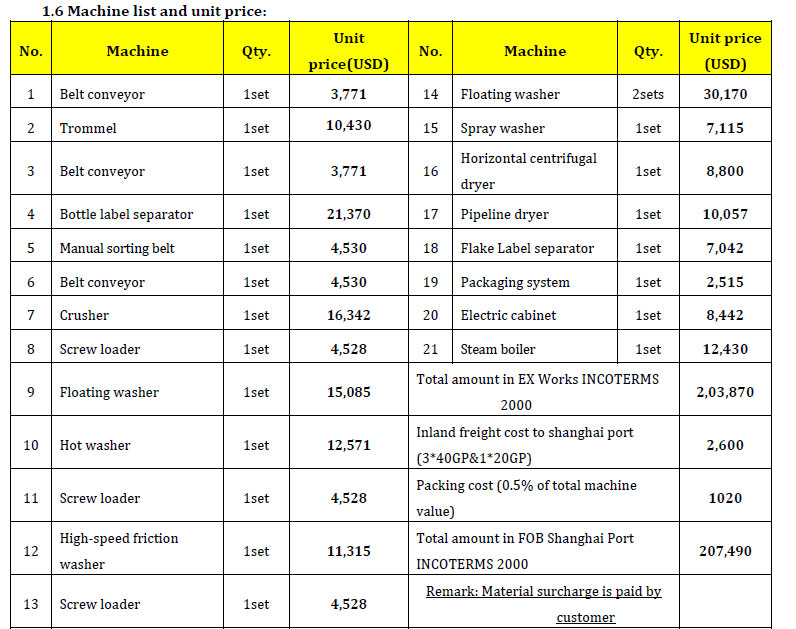

(For images, please see next pages)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}