For Sale - PCM - 4285 - Jagmohan Accumulator Type Blow Moulding Machine Water Tanks

Reference Numbers

PCM - 4285Product

Jagmohan Accumulator Type Blow Moulding Machine Water Tanks

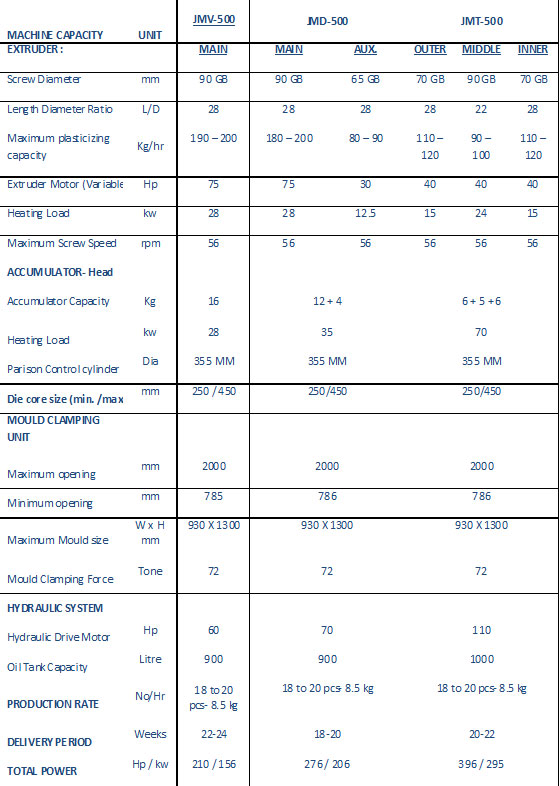

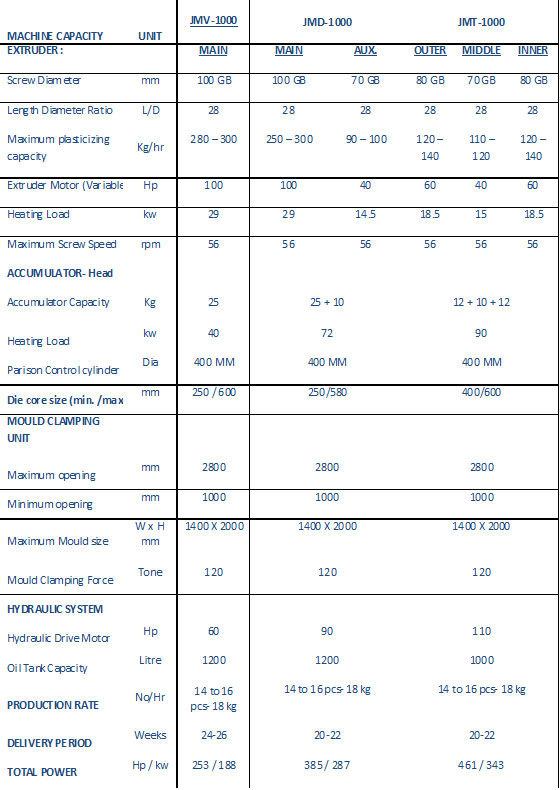

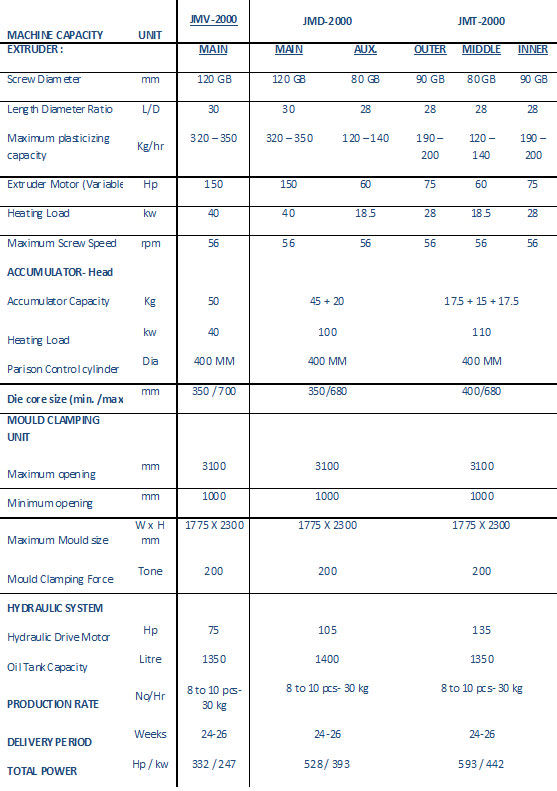

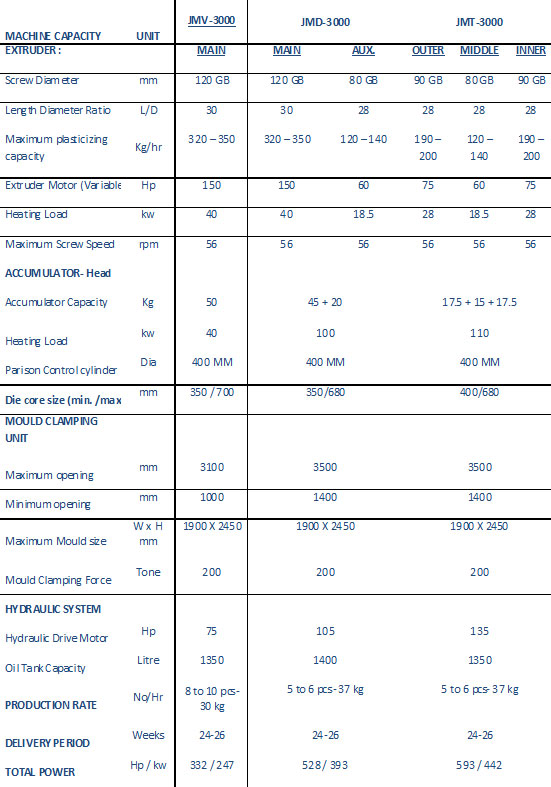

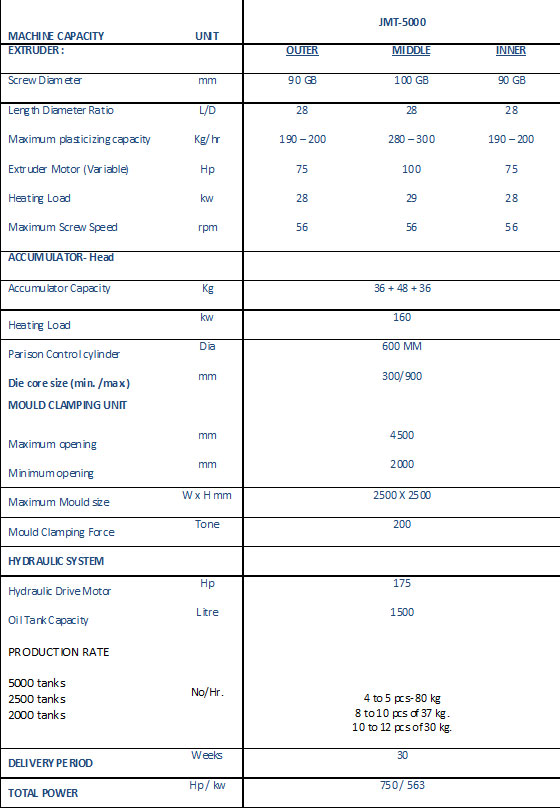

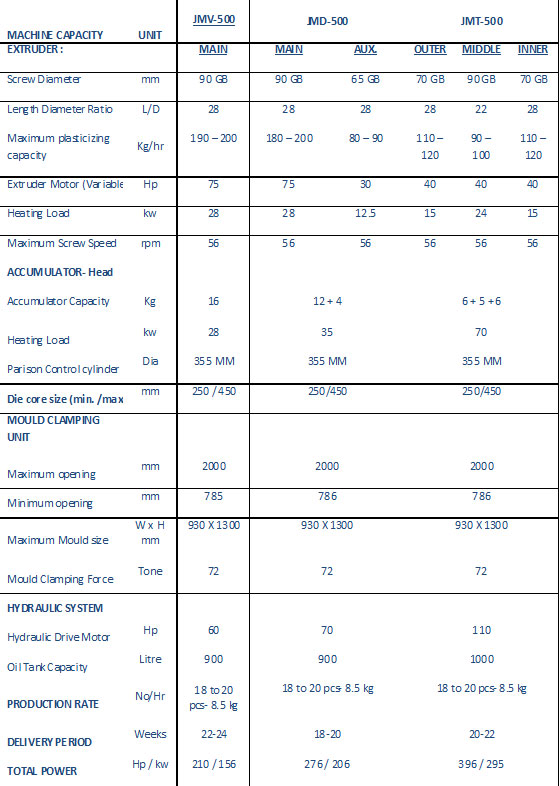

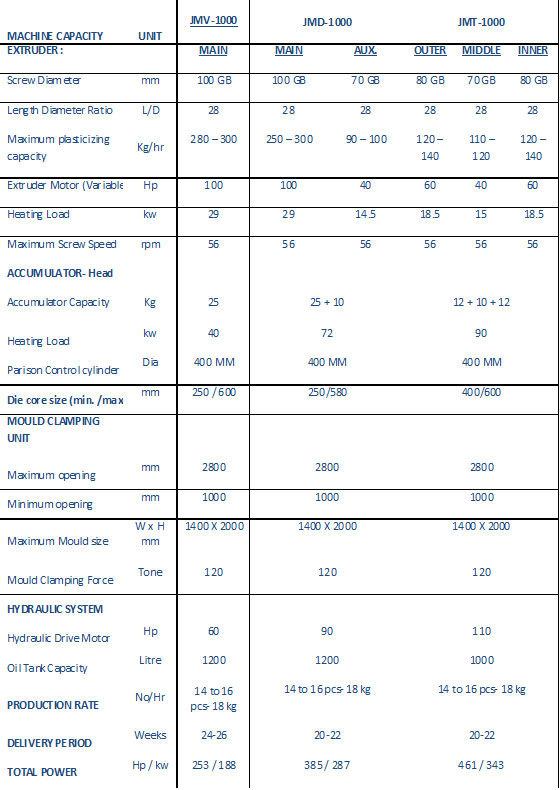

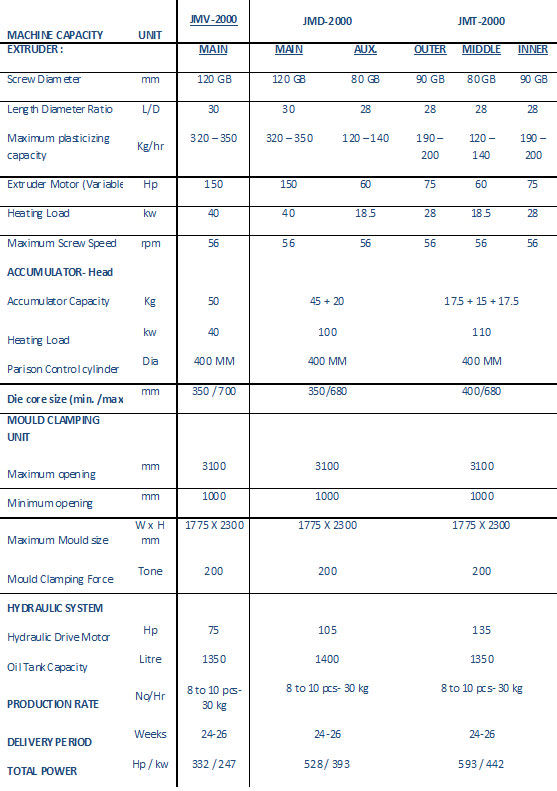

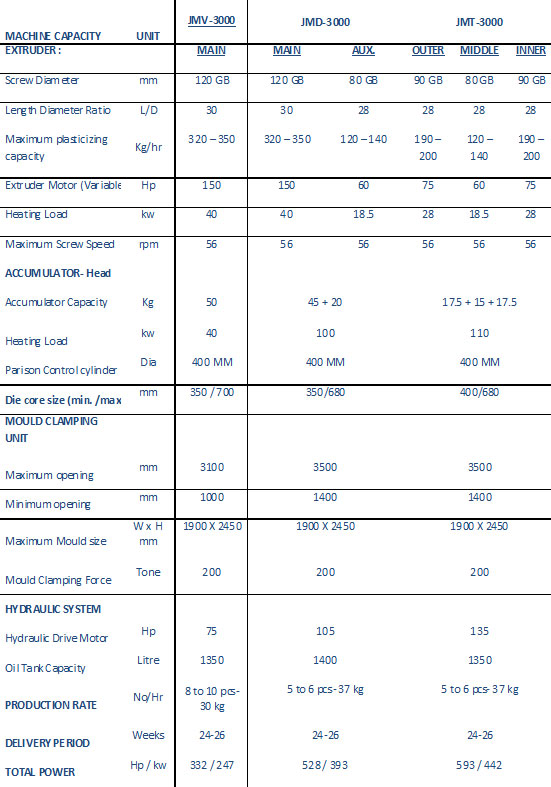

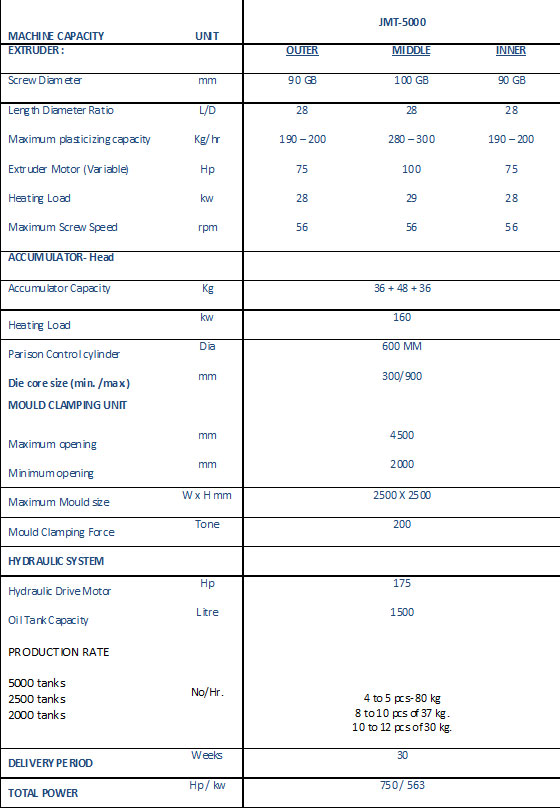

Product Range: 500 Litres to 5000 Litres

Variants: Single Layer, Double Layer, Triple Layer

Why Blow Moulded Tanks?

- Material out is of HM/HDPE, so strength is much higher.

- Much Lower weight than Roto with better stability and leading to cost/Kg. saving.

- Production rate is 10 - 12 times higher.

- Pulverising and Pelletizing Process not required.

- Option for Interchangeable Moulds for output of various capacities.

- Surpassed all relevant quality test.

- Threaded Lid.

Standard/optional features

- PLC control with MMI

- FIFO accumulator head

- A.C. Variable frequency drive (Extruder)

- Yuken Hydraulics

- Angular Blowing attachment (30°)

- Filter, Regulator & Lubrication for pneumatics

- Helical Gear Box with built in housing

- Safety guard. (Electrical)

- Hydraulic Shooting for neck calibration

- 3 stage Parison programmer

- S. S. Cooling Arrangements

- Return Line Filtration for Hydraulics

- Multipoint Parison Programmer

- Angular blowing attachment (45°)

- Hopper Loader.

- Leak tester arrangement

- AC for control panel

- Energy Meter

- Automatic Container Gripper

- Unscrewing blow pin

- Pre sealing & pre blow adjustment

- Motorized Up down, to & fro adjustment of Clamping Unit

- Auto Lubrication

- Mould movement arrangement

(For images, please see next pages)

For More Details Contact:

Jagmohan Pla-mach Pvt Ltd Mumbai, India

Mr. Narendra Malviya / Mr. Sayan Karan

Mob: +91 9320630017 / +91 9321450017

Email: export@jagmohan.com / overseas@jagmohan.com / info@jagmohan.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}