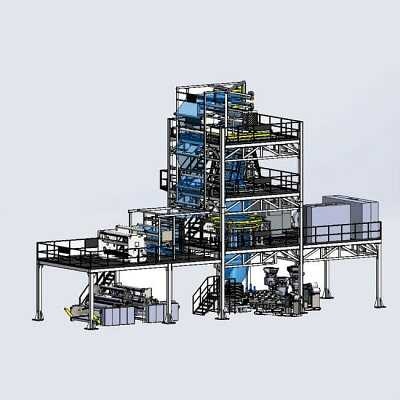

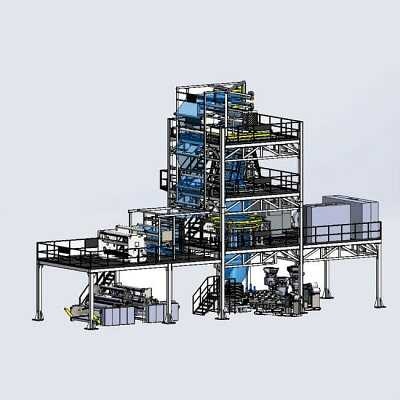

For Sale - PCM - 4804 - BETAFLEX 5 Layer Co-Extrusion Blown Film Line

Reference Numbers

PCM - 4804Product

BETAFLEX 5 Layer Co-Extrusion Blown Film Line

Final Product:- LL / LLDPE

Material Used:- LDPE, LLDPE, Tie, Virgin Raw Material

Output Range:- 450 - 600 Kg/Hr (Depends On Extruder's Size)

Film Layer:- Five Layer (Internal Bubble Cooling System)

Screw Diameter:- 55 / 65 / 75 / 90 MM

Screw L/D:- 30:1

Layflat Width:- 1800 - 2500 MM

Micron Thickness:- 20 - 200

Model:-

1) SE5HR 2300 POD FIVE LAYER

Screw Diameter : 55 / 65 / 75 / 65 / 55 MM

Layflat Width : 1450-2200 mm

Max. Output : 500 kg/hr

Thickness : 20-200 mm

2) SE5HR 2600 POD FIVE LAYER

Screw Diameter : 65 / 75 / 90 / 75 / 65 MM

Layflat Width : 1750-2500 mm

Max. Output : 600 kg/hr

Thickness : 20-200 mm

POD Concept:

Non barrier five layers film comes from a strong market demand for sustainable specialty films with reduced thickness, good sealing and optical properties.

The five-layer technology for Polyolefin Dedicated Film (POD) enables production economies and quality enhancement. Polyolefins are a family of polymers produced from a simple olefin (also called an alkene) as a monomer.

The two most common classes are PolyEthylene (PE) and PolyPropylene (PP).

Polyolefins are used in a wide range of Medical Applications including Dilators, Introducers, Packaging, Film and Molded Components.

They generally offer good Biocompatibility, Chemical Resistance and Lubricity while offering acceptable tensile and impact properties. However, care needs to be taken when evaluating the sterilization of the materials as they have limited temperature and radiation resistance.

The Lowest Wetted Surface Area compared to all dies in industry

Shortest Flow Grooves

No restriction on # of spirals

30% to 50% less melt volume

Individual internal heat zones

Only 10 parts for Five Layer

Much faster heating & cooling

Easy to assemble & disassemble

For More Details Contact:

Shubham Extrusion Technik Pvt. Ltd.

Mr. Kartik Dave

Mobile No:07573016126

Email ID: shubham.extrusion1997@gmail.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}