For Sale - PR - 2463 - Polycarbonate Solid Sheet

Reference Numbers

PR - 2463Product

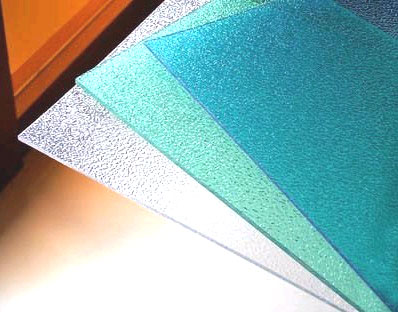

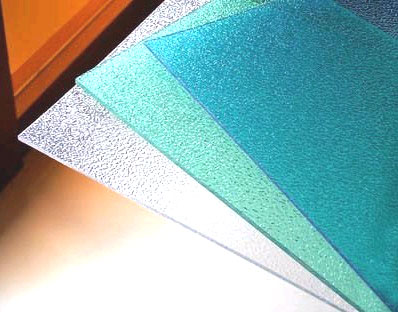

Polycarbonate Solid Sheet

PC Embossed Sheet

PC embossed solid sheet is made by polycarbonate resin. On the basis of common pc solid sheet's technique and improvements of molds and production, the optical properties are changed as the surface structure of the product varies. Single side of pc embossed sheet contains UV protective layer, therefore, its mechanical properties, fire retardation, applicable temperature and chemical properties are consistent with common solid sheet. By changing the physical shape of the surface, when light gets through the embossed sheet, it produces light scattering to get a vague hazy effect.

- Thickness: 2.7 mm

- Length: 30 M (98FT)

- Width: 2100 mm (7FT)

- Color: Clear, green, blue, etc.

- Special specification and color are available.

- The surface is paved by single-face PE protective film.

Features:

- Light transmission: 12% to 82% depending on color and thickness

- Impact resistant: 80 times than that of glass, 15 times than that of acrylic sheeting

- Temperature service: -40°C to 120°C

- Light weight: only 1/12 of the weight of glass at same thickness

- UV Protection

- Fire retardance: Rated Class B1

- Sound & Heat Insulation

Storage, transportation and usage

- Prohibit contact with wet cement surface and acid, alkaline material surfaces.

- Prohibit contact with organic solvents and glue, paint composed thereof.

- Keep the frame clean and the surface of rabbet groove flat. Dust and dirt of the sheet are generally wiped by soft cloth or sponge with mild detergent first and then washed by water thoroughly.

- Choose the right thickness, allow flexure radius.

- If use self drilling screws for fixing, the hole must be pre-drilled, and the aperture should be 1.5 times larger than the diameter of the screw. Do not tighten the screw strongly, otherwise stress will arise, and crack on the sheet surface will appear.

- Remain space for expanding, pay attention to inserting depth. Expanding Value = linear expansion coefficient × length × the maximum temperature variation (linear expansion coefficient of pc sheet is 7×10-5mm/mm/°C).

- Use neutral glass cement and right gasket. Never use gasket of PVC material.

- Use electrical tools (tungsten carbide saw) to cut, stabilize PC sheet to prevent their vibration. Don't peel off protective film when cutting.

- In case that marks have to be made before cutting, try to mark on protective film. If the marks must be made directly on PC sheets, use wax crayon instead of any sharp tool to mark.

- Never peel off protective films until installation is completed.

- It is suggested that smooth side is installed towards sun in order to realize the effect of the UV protective layer.

Application

- Commercial Building Lighting

- Industrial architecture lighting

- Stadium roof and indoor play area

- Transportation infrastructure

- Residential architecture lighting

- Exterior protected construction and curtain wall

(For image, please see next page)

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}