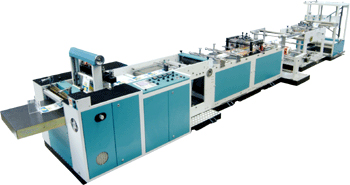

For Sale - PTP - 2085 - Combined Pouch Making Machine

Reference Numbers

PTP - 2085Product

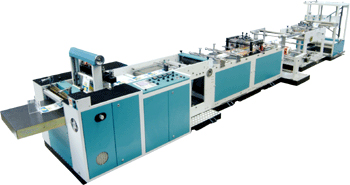

Combined Pouch Making MachineManufacturer

XL Plastics, India

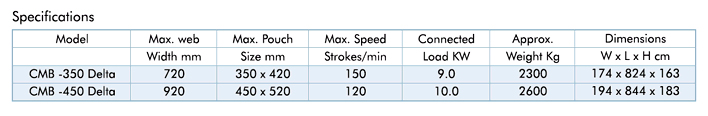

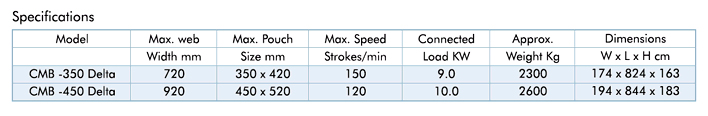

XL Plastics Delta Series Models: CMB 350 Delta / CMB 450 Delta

Features:

- Speed up to 150 strokes/min

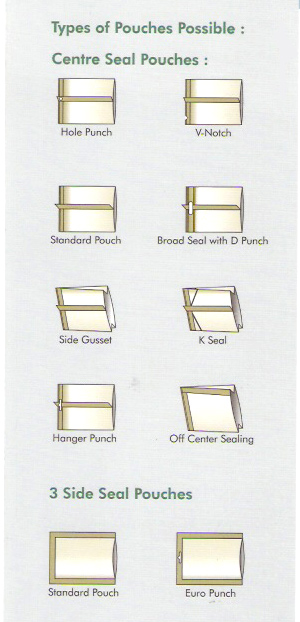

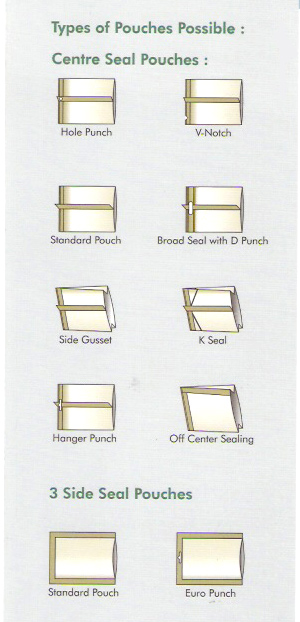

- Converts both center seal and three side seal pouches

- Servo motor for indexing and accuracy

- Microprocessor controlled with digital display

- Keypad setting for speed, size and count

- Photocell control to convert printed film

- Continuous forming / folding, sealing and feeding

- One set cross sealing jaws

- Vertical and horizontal unwind stands

Advantage:

Machines manufactured by XL Plastics are designed for continuous duty and maintenance free operation. Some of these standard features on all the machines not only make them more reliable but also efficient and operator friendly.

- Fully assembled and pre-wired: The machine is fully assembled and tested prior to shipping. The pre wired and modular design of the machine makes it easy for installation and startup.

- Standard Machine: The standard machine comprises of an horizontal and vertical unwind stand with brake, continuous folder, center sealing and lateral sealing section, pull rolls, dancing rolls, photocell unit, cross sealing station, synchronizer, draw rollers, shear cutting and stacking table.

- Motors and drives: Main motor and all other motors are AC motors with variable speed control by inverter drives.

- PID temperature controller: PID temperature controller with digital display maintains accurate sealer temperature to give consistent quality of seal.

- Print Registration Photocell: The best quality Japanese / European photocell is used to give accurate print registration

(For more details and images, please see next pages)

For More Details Contact:

XL Plastics

Mr. Vivek Vora

Tel.: +91-265-2638125 / 2638026 / 2652118

Fax.: +91-265-2638661 / 2646716

E-mail: info@xlplastics.com

Website: http://www.xlplastics.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}