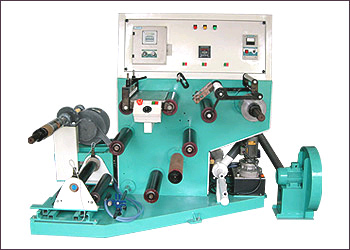

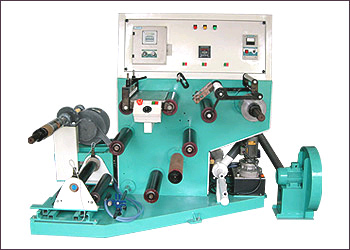

For Sale - PTP - 3330 - Inspection cum Doctoring Rewinder

Reference Numbers

PTP - 3330Product

Inspection cum Doctoring RewinderManufacturer

C. Trivedi & Company, India

Specially designed and developed doctoring machine to high accuracy. Model Autodoct

In any paper, film and foil conversion industry, slitting is invariably the last operation to be performed. At the time of slitting, irrespective of the brand and type of slitting machine employed, ten to twelve percent of the output (i.e. One out of 10 or 8 slit to size bobbins) is not of saleable quality. This is a Harsh practical fact and the reasons thereof are quite well known. The model is specially designed for correcting badly wound roller for removing the misregistered and rejected material before it goes to final delivery, in order to rectify salvage such rejection, the doctoring machine has been specially developed through the R & D efforts at C.T.

Specification:

- Max. width of parent roll: 500 mm.

- Max. parent reel diameter: 400 mm.

- Max. rewind reel diameter: 400 mm.

- Max. designed speed: 120 meter per min.

Balancing body

- Movable unwind stand for edge guiding.

- Mechanical 1.5 / 2.5 kg. Magnetic particle powder brake with tension controller, torque control potentio meter and on-off switch.

- 1 hp / 12 hp Dyna drive with torque 0.5 kg. Mt 120-1200 rpm and AC 40 controller.

- 48 pole AC techno generator (20 V AC / 1000 rpm. line speed)

- S.S.316 made inspection table with bracket.

- Single side mounted 85 mm aluminum ideal roller with balance bracket.

(For picture, please see next page)

For More Details Contact:

C. Trivedi & Co.

Mr. Bharat Trivedi

Tel.: +91-79-4008 3551 / 4008 3552 / 4008 3553

E-mail: ctrivedi@ctrivedi.com, info@ctrivedico.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}