For Sale - PTP - 3463 - High Speed Twin Track T-shirt Bag Making Machine

Reference Numbers

PTP - 3463Product

High Speed Twin Track T-shirt Bag Making MachineManufacturer

XL Plastics, India

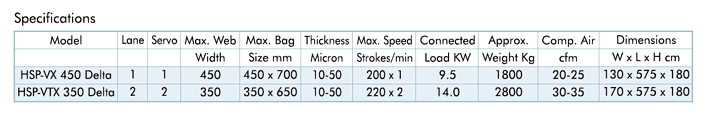

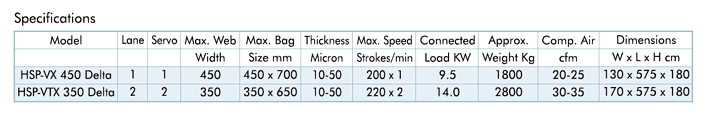

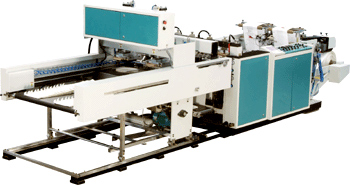

1) High Speed Twin Track T-shirt Bag Making Machine:

- Model: HSP-VTX-350 Delta

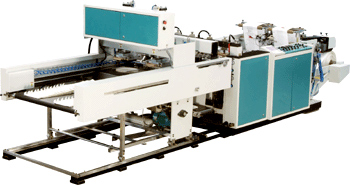

The high speed twin track T-shirt bag making machine model HSP-VTX-350 Delta is able to run at a maximum speed of 220 strokes / minute and thus get a production of 440 bags / min. You can simultaneously run 2 printed pre-gusseted tubular roll on the machine. The machine is equipped with two servo motor and drive system with dual photocell for sensing the print mark and thus it is possible to convert 2 rolls simultaneously

The film is sealed and cut using a hot knife and stacked together automatically into bunches of 50 bags. Once the batch count is reached, the gripper function on the machine will take the bunch of bags forward to the online punching station where the handle punching is done and you get the ready finished bags on the auto conveyor

Features:

- High speed up to 220 strokes / min x 2 tracks

- Pneumatic lifting of unwind roll for easy loading

- Servo motor for indexing and accuracy

- Photocell to convert printed web

- Microprocessor controlled with digital display

- Keypad setting for speed, size and count

- Surface driven unwind to minimize stretching of film

- Finished bags ready for packing

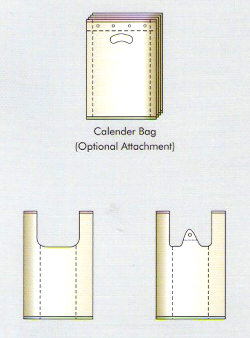

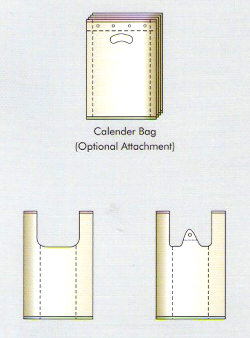

- Folding attachment (optional) for punched bags

- Edge guiding system for uniform stacking of bag

2) High Speed Single Track T-shirt Bag Making Machine:

- Model: HSP-VX 450 Delta:

The high speed automatic T-shirt bag making machine model HSP-VX-450 Delta is a high speed bag making machine to convert up to 200 bags / minute. It is possible to convert 1 pre-gusseted tubular roll of maximum width of up to 450 mm

Features:

- High speed up to 200 strokes / min.

- Finished bags ready for packing

- Servo motor for indexing and accuracy

- Photocell to convert printed web

- Microprocessor controlled with digital display

- Keypad setting for speed, size and count

- Surface driven unwind to minimize stretching of film

- Folding attachment (optional) for punched bags

- Stacking and conveying of finished bags

- Automatic removal of cut-out waste

- On-line blocking, punching and conveying

- Edge guiding system for uniform stacking of bag

(For more details and images, please see next pages)

For More Details Contact:

XL Plastics

Mr. Vivek Vora

Tel.: +91-265-2638125 / 2638026 / 2652118

Fax.: +91-265-2638661 / 2646716

E-mail: info@xlplastics.com

Website: http://www.xlplastics.com

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}