For Sale - CS - 46

Reference Numbers

CS - 46

We have extensive facilities for Rapid Prototyping in a number of materials including ABS, Nylon, Glass-Filled Nylon, Polystyrene, Flexible Elastomer. All models are finished by its skilled team, who achieve an extremely high quality of surface finish while still preserving the specified tolerances. These skills and attention to detail are reflected in the vacuum or investment casting.

Facilities include:SLA 250

FDM 1600, FDM 2000

EOS P360, EOS M250

Mould Fabrication & moulding:

We offer customer extremely short lead times by adopting concurrent engineering strategies, and tool manufacture can begin simultaneously with product development.

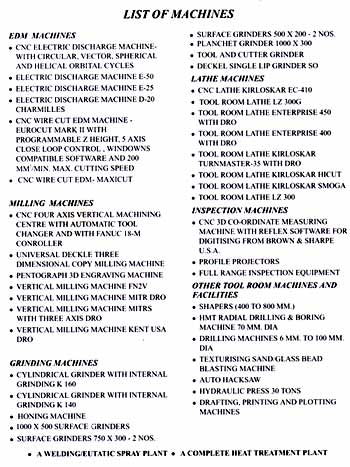

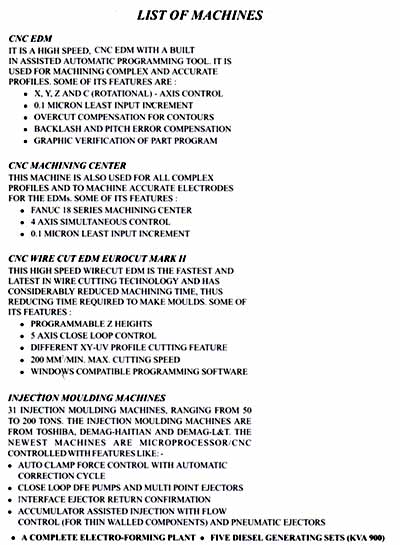

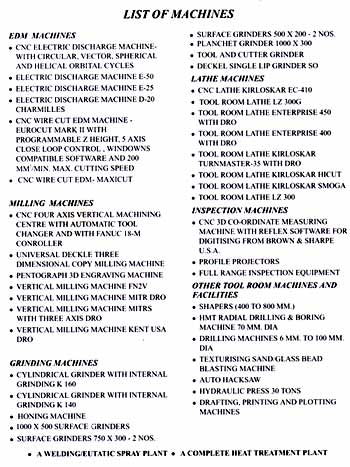

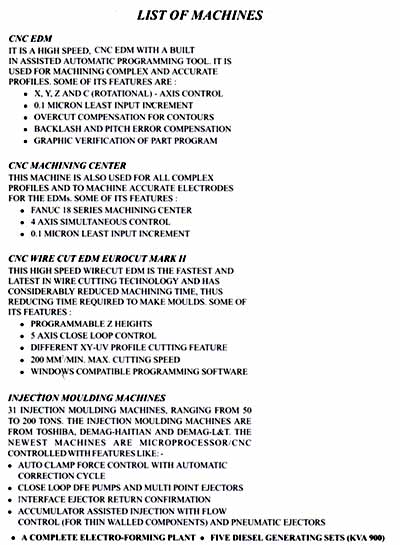

By utilising modern CAD/CAM software available, complex 3D geometry can be created quickly and efficiency for machining directly to core/cavity details or electrode manufacture for EDM purposes.

Moulds can be fabricated for Injection Moulding and for pressure die casting

Other services Include:-

Reverse Engineering using white light and laser scanning followed by surface and solid modeling.

2D to 3D CAD conversion

Computer aided Engineering

Plastics flow simulation using Moldflow

Structural analysis using ANSYS

Metal components using investment casting and sand casting.

Excellent project management skills are utilized to integrate all areas of product development, to provide the customer best quality, shortest possible lead times at competitive costs while maintaining confidentially of designs.

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}