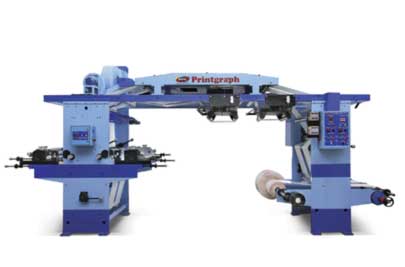

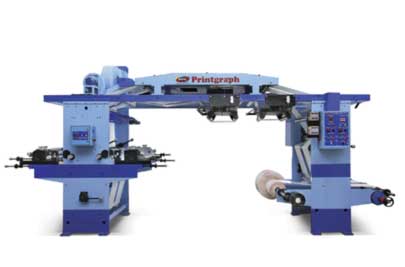

For Sale - PNE - 4373 - 2 to 8 Colour Double Track Flexographic Printing Press

Reference Numbers

PNE - 4373Product

2 to 8 Colour Double Track Flexographic Printing PressManufacturer

Perfect Printgraph Engineers LLP, India

Series: Double Track Series

Number of Printing Station: 2 to 8 Color.

Web Width: 500 mm to 1500 mm (250 mm + 250 mm to 750 mm + 750 mm).

Print Width: 400 mm to 1400 mm (200 mm + 200 mm to 700 mm + 700 mm).

Printing Repeat: 350 mm to 800 mm.

Maximum Reel Outer Diameter at Unwind & Rewind Station: 800 mm.

Maximum Reel Weight at Unwind & Rewind Station: 250 kgs.

Printing Possibilities: Variable as per no of color of Machine.

Mechanical Speed: 80 Meter per minute.

Printing Speed: 70 Meter per minute.

Power Requirement: Variable as per Machine.

Supply Voltage: 415 V, 3 Phase, 50 Cycles / sec, 4 wire or as required.

Floor Space Length/Width/Height: Variable as per machine.

Substrates Printable: LD, LLDPE, HM, HDPE, P.P - Extruded Plastic Films.

Features of the Machines:

4 Motor drives technology for:

- Main Printing Station

- Unwind Station

- Outfeed Station

- Rewind Station

- Opto electronic web guiding system:

Digitally controlled web guiding for precise guiding of web

- Automatic tension control system :

AC motor drive technology for precise tension control and load cell feedback control provided on unwind, outfeed and rewind station to maintain uniform tension throughout the entire roll.

- Automatic movement of the printing decks by precise circulating ball screws with motorised advancement.

- Motorised transversal printing tension of register controlled via PCL.

- Human Machine Interface (touch screen controls).

- Pneumatic system :

Provided for continuous rotation of inking rollers and auto lifting of plate cylinders when machine is printing in OFF mode. This prevents drying of inks on the Anilox Roll.

- Chamber doctor blade system:

For uniform and controlled ink supply on the anilox roll.

- Ceramic anilox rolls:

Higher mesh laser engraved anilox rollers for precise transfer of ink to achieve better and enhanced print quality.

- Motorised ink pump

Air operated pumps for controlled circulation of ink between ink tank and chamber doctor blade.

- Web video system:

Web inspection system, equipped with high quality color camera, quick zoom & split screen, mounted on motorised traverse bar to monitor complete print at all speeds.

- Pneumatic shaft:

Provided on unwind and rewind stations for quick and easy loading and unloading of the parent roll.

- Pneumatically operated nip rollers:

To maintain uniform and precise tension at printing, infeed and outfeed stations.

For More Details Contact:

Perfect Printgraph Engineers LLP,

Passion, Innovation and Service.

Rakesh Parmar (Contact No: +919820042647)

Ravi More (Contact No: +91 9323948916)

Email ID: info@printgraph.in

Website: www.printgraph.in

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}