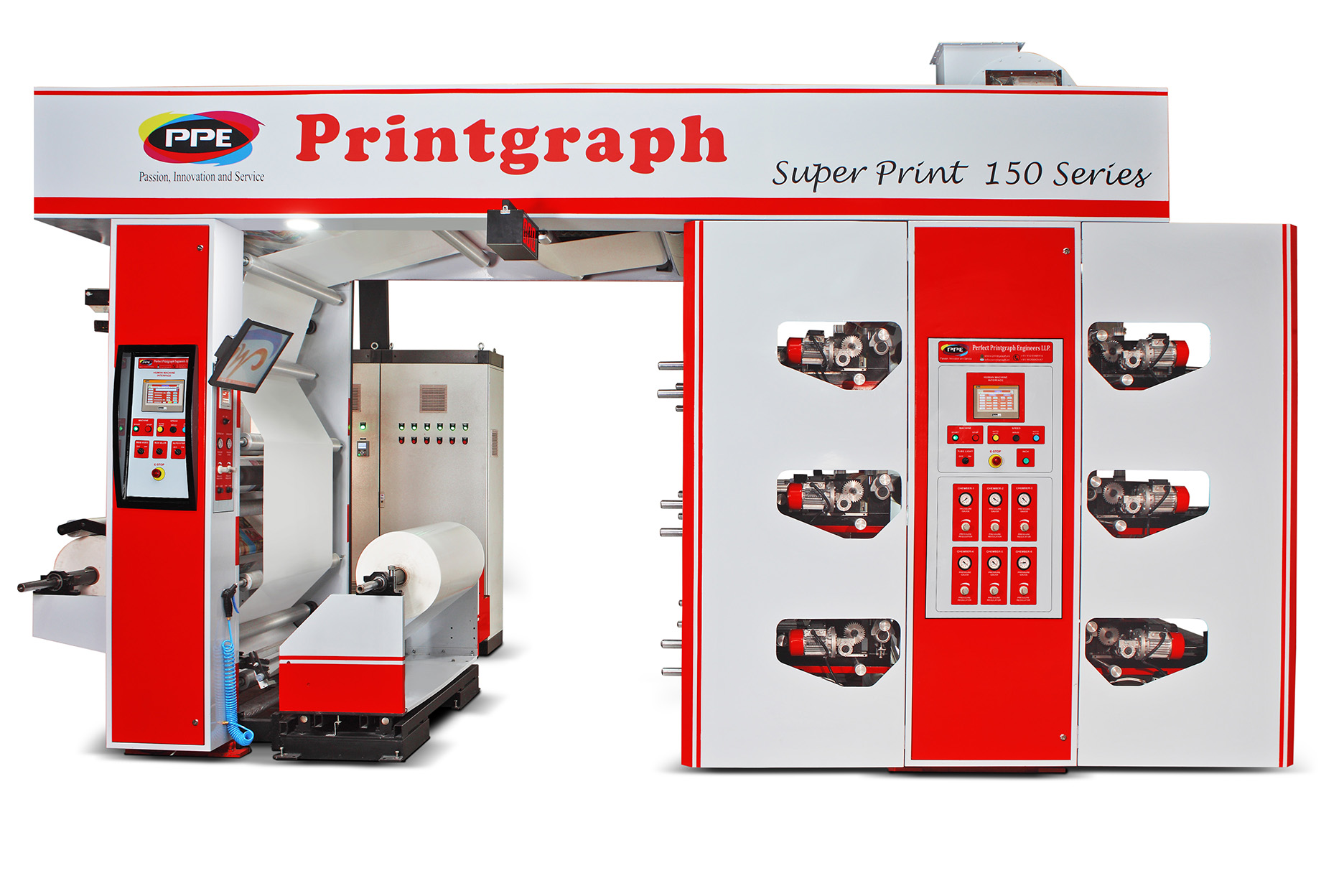

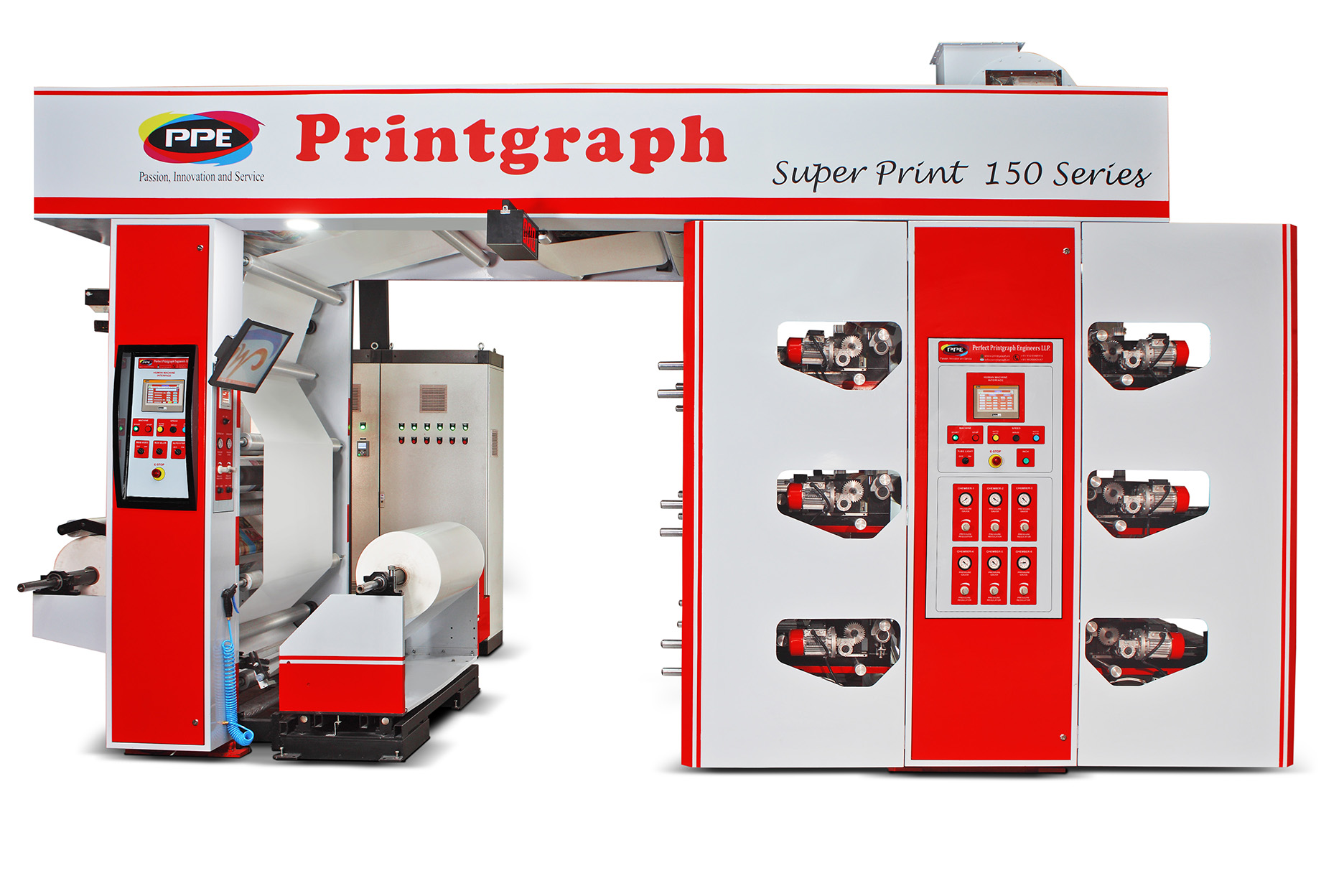

For Sale - PNE - 4400 - Flexo Printing Press for Plastic – Stack Type – Super Print 150 Series

Reference Numbers

PNE - 4400Product

Flexo Printing Press for Plastic – Stack Type – Super Print 150 SeriesManufacturer

Perfect Printgraph Engineers

Speed: 200 m.p.m

Designed For

1. Shopping Bags.

2. BakeryProducts.

3. FoodIndustries.

4. Oil & DairyIndustries.

5. PaperIndustries

Technical Specification

Type of Machine : High Speed Flexo Printing Press - StackType.

Series : Super Print 150 Series

Number of Printing Station :4 to 12 Color.

Web Width : 500 mm to 1500 mm.

Print Width : 400 mm to 1400 mm.

Printing Repeat : 300 mm to 800 mm.

Maximum Reel Outer Diameter at Unwind & Rewind Station :800mm

Maximum Reel Weight at Unwind & Rewind Station : 300 kgs.

Printing Possibilities : Variable as per no of color of Machine.

Mechanical Speed : 200 Meter perminute.

Printing Speed :180 Meter perminute.

Power Requirement : Variable as per Machine.

Supply Voltage : 415 V, 3 Phase, 50 Cycles/sec, 4 wire or asrequired.

Floor Space Length/Width/Height : Variable as per machine.

Substrates Printable : LD,LLDPE, HMHDPE, POLYPROPYLENE, POLYSTER, PEARLISED AND LAMINATED ALUMINIUM FOILSETC., B.O.P.P, THINFOAM SHEETS

Features of the Machines:

- 5 Drive Technology with Asynchronous AC ServoMotor.

- Enclosed Chamber Doctor Blade System:For uniform and controlled ink supply on the AniloxRoll.

- Ceramic Coated Anilox Rolls:Higher mesh laser engraved Anilox Rollers for precise transfer of ink to achieve better and enhanced printquality.

- Motorised Ink Pumps for controlled circulation of ink between Ink Tank and Chamber DoctorBlade.

- AutomaticTension Control System:Asynchronous AC Servo Motor DriveTechnology for precise tension Control and Load Cell feed back control provided on Unwind,Infeed,Outfeed and Rewind Station to maintainuni form tension through out the entire roll.

- Automatic move mentof the printing decks by precise circulating balls crewswith motorised advancement.

- Opto Electronic Web Guiding System : Digitally controlled web guiding for precise guiding of web

- Motorised transversal printing register controlled viaPLC.

- Pneumatic System:Provided for continuous rotation of in king rollers and auto lifting of plate cylinders when machine is printing in OFF mode. This prevents drying of inks on the AniloxRoll.

- Human Machine Interface (Touch ScreenControls).

- Web Video System:Web inspection system, equipped with high quality color camera, quick zoom & split screen, mountedon Motorised traversebar to monitor complete print atall speeds.

- Pneumatic Shaft:Provided on Unwind and Rewind Stations for quick and easy loading and unloading of the parentroll.

- Pneumatically Operated Nip Rollers:To maintain uniformand precise tension at printing,Infeed and oufeed stations.

The actual production speed will depend on the type, thickness, quality of the material to be printed, No. of Color, Inks,Photo Polymer Plates, Quality of Inks, Solvents and Operators skill.

- Centralized high speed drying system.

** Depend upon themodel.

*** Due to regular R &D, Speci?cation may undergo minor variations without priornotice.

Optional Features:

• Sleeve Technology.

• Automatic Viscosity Controller.

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}