|

Technical

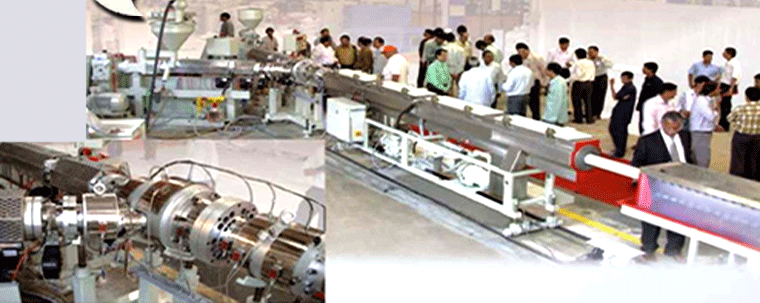

features Twin Screw Extruder-Main : 68mm (28:1) Twin Screw Co-Extruder : 65mm (22:1) |

Demonstration

Highlights |

| Advantages

over Compact RPVC Pipes |

|

Non-Pressure Applications | |||

|

Overall density reduction |

Drainage and Sewage Pipes | ||||

| Lower cost per

pipe length |

Ventilation Pipes | ||||

| Lower Thermal Coductivity | Cable Protection Pipes | ||||

|

|||||

| Kolsite Battenfeld RPVC Foam Core Pipe Plant |

||

| A Cost Effective, Extrusion System with: | ||

| Main Extruder to produce the middle foam layer. | ||

| Co- Extruder to produce the inner and outer skin layers. | ||

| Combined

Dosing and Horizontal Feeding Unit to add the foaming agent. |

||

| Specially designed PVC Spider Die. | ||