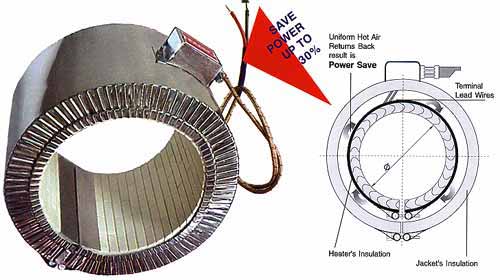

| Ceramic Jacketed Heaters |

|

| Features: 1. Especially to heat the cylinders (barrels) on all types of plastic(s) processing machinery. 2. The Key to the ceramic-jacketed heaters is its superior design to save power. 3. Outer insulation jacket conserves energy. 4. Up to 30% of power consumption reduces. 5. Maximum watt density = 50 watts/square inches. Note: Incase where high watt densities are required, it is important that all heaters should be used with appropriate, approved and precise temperature control/sensor device(s). 6. Maximum sheath temperature up to 800 degree celcius. 7. Use of special ceramic material "steatite" with high thermal conductivity. 8. The model is designed & constructed with special effective dual insulation which reduces the rate of heat radiation / loss, resulting swift rise in the temperatures of the object to be heated. 9. Uniform heat distribution throughout the barrel. 10. Reduction of thermal shocks on polymer melt, resulting in improved quality. 11. Good shine of your finished products. 12. Increases productivity. 13. The heaters meet progressive requirements of the plastic processors. |