| Pressing Capacity | Tons | 40 | 65 |

| Platen size | mm | 350 * 300 | 450 * 400 |

| Daylight | 30 | 500 | 600 |

| Working Stroke | 14.4 | 200 | 250 |

| Motor | 77 | 3 HP | 5 HP |

| Height of machine | metre | ||

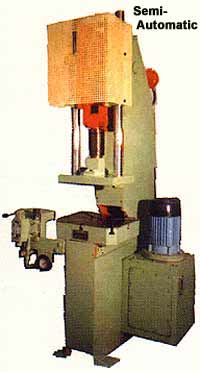

| Floor space Semi-auto | metre | 1 * 0.75 | 1.2 * 2 |

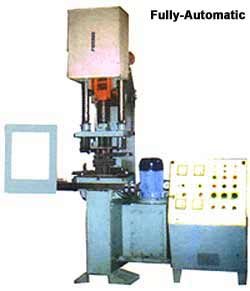

| Fully-auto | metre | 1 * 1.75 | 1.2 * 2 |

Features:

1. Hydraulically operated, toggle type machine.

2. Powerful mould pressing, due to toggle system operation.

3. Pressing force can be adjusted by setting the hydraulic valve.

4. Very little noise of operation.

5. Occupies very little space.

6. Semi-automatic models are operated by hand hydraulic valve actuation.

7. Fully automatic models operate through control panel.

8. Fully automatic models are provided with top and bottom ejection systems.

Ejection system available extra for semi

automatic model.

9. Transfer moulding facility can be provided, extra. Standard machine

is suitable for compression moulding.

Additional details for fully auto model:

Operating cycle:

Operater closes safety gate-fast approach of moving platen (top platen

)-slow close of mould-time delay-breathe (for escape of entrapped gases)-

pressure build-up-cure-slow open-fast return of moving platen-time delay-ejector

forward-time delay-ejector return-operator opens safety gate-repeat.

Automatic ejectors are provided for both bottom ejection and top ejection.

The machine is designed to put off the motor during idle time of the cycle

viz.

Curing time as well as at the end of one complete cycle, to conserve power.

The motor starts automatically every time a fresh cycle is started by

operation of the safety gate. The machine is fitted with electronic temperature

controllers for both the mould halves.

Hypress machines are suitable for moulding switches, sockets, plugs, heat-proof

garment buttons, tea-set items, dinner set items, automobile and electrical

control panel accessories, etc. using thermosetting materials like bakelite,

urea formaldehyde, melamine formalde-hyde, and rubber.