Post production operations being important, our machines produce films

which run trouble free on 'FFS' machines. Sealing, printability, contact

clarity, impact resistance and most important blendability of various

raw materials to meet the most demanding packaging requirements - which

cannot be obtained from just one polymer - are being obtained through

multilayer films.

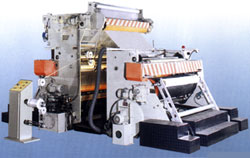

Hence, multi layer films produced on three layer film plants become functionally

ideal and the most cost - effective for the combination of different polymers.

Extruders are manufactured in

• Size ranges from 47 mm to 58 mm diameter

• L / D ratios of 26:1

• Output range from - 105 kgs/hr to 220 kgs/hr

• Gear boxes with integral thrust housing

• High efficiency blowers, heaters insulated for safety purposes and heat conservation to achieve precise temperature control.

• Computer designed barrier screws tailored to suit various resin grades and process requirements to ensure maximum outputs with quality product.

• Water-cooled feed sections.

• Variable speed drives [AC/DC] sized to suit the application and output rate.

• All extruders mounted on robust platform rotating on a heavy duty slewing bearing to give jerk free operation controlled by PLC. The platform has one / two speed AC motor to provide single or multiple oscillation speeds to suit different line speeds.

• Easy-use centering screws to adjust die lip gap to accurate thickness control

• Three spiral material distribution systems designed and made from best quality die-construction materials stabilized to prevent distortion due to high temperatures.

• Smooth spiral passages precision machined, mirro polished and hard chrome plated to allow uninterrupted flow of plastic melt to prevent degradation.

• Highly efficient, energy saving, insulated ceramic heaters for longer life on die zones for precise heat control

• For increased cooling efficiency and production rate, heat exchanger is included in high output models.

• Aluminium cast aerodynamic type double lip air cooling ring with multiple entries and circular inserts to guide air impinging on film bubble.

• Irish ring to create air cylinder along the bubble for optimum cooling.

• Membrance filter at the suction of blower to arrest dust particles.

• AC frequency variable drive for blower to control air flow as optional.

• Self centering air ring mounting on the die head enabling free movement near the die.

• Single point control mechanism to adjust arms to bubble diameter.

• PTFE rings on basket arms to provide low friction to moving film.

| |

to handle sticky materials |

railings.

• Nip system - steel chrome plated roller and rubber roller.

• Pneumatic nip operation.

• Water cooling provided in steel roller for heat removal.

• Speed variation - stepless control up to 60 meters per minute through

reduction gearbox and AC variable drive.

• Suitable balanced guide rollers to support lay flat film to winder.

• Synchronisation of nip and winder drives.

• Chain pulley block mounting provision.

• Sophisticated, process control panel with IP 20 protection

• Microprocessor based PID temperature controllers

• DOL Starter / AC variable frequency drives for Air Ring Blower

• PLC based control for Single / Two speed motor of oscillating platform

• Extruder thyristor drives with Tacho Feedback & AC frequency drives for Nip Rolls and Winder Drums

• Film winding shafts - two main [and two standby]

• Rubber coated drums having AC frequency Variable Drives

• Set of pressure-cum-pulling rollers of rubber and ebonite with AC frequency Variable Drive

• Slitting and Trimming arrangement

• Polyband expander rolls to spread wrinkles / creases.

• Speed range:

[ infinite variation ]

[ infinite variation ]

• Trim conveying with blower.

• Hopper loader

• Load cell for web tension control in close loop with winder drum drives

• Roller flattenning board

• Chain pulley block arrangement

| Specifications | : | |

| Max. Web Width | : | 1500 mm |

| Line Speed | : | upto 60 mtrs/min |

| Nip Roller | : | 1 HP AC Variable Vector Control Drive |

| Winder Drum | : | 2 HP AV Variable Vector Control Drive at each station |

| Polyband Expander | : | Driven in synchronization with winding drum at each station |

| Film Roll | : | 1000 mm Dia. |

| : | 1000 Kgs in weight |

| Salient Features | : | |

| Shorter web path | - | for easier safe operation. |

| Load Cell | - | Tension control for low gauge film, good winding and GSM Control |

| Automatic controls through PLC for | - | Splicing with preset length counting system |

| - | Roll unloading | |

| - | Reel shaft changeover. | |

| Air expanding reel shaft | - | for multiple roll winding. |

| Centre Slitter | - | 2 sets for slitting different widths at each station |

| End trim coreless two station winder | - | for winding side trims |

| Plant

Model |

27347 |

25855 |

25958 |

| Screw

Diameter |

3

x 47mm |

3

x 55mm |

3

x 58mm |

| L

/ D Ratio |

26:1 |

26:1 |

26:1 |

| Max,

Output [kgs/hr.] |

105 |

180 |

220 |

| Main

Drive [HP DC] |

15

x 3 |

30

x 3 |

50

x 3 |

| Layflat

width [mm] |

600

- 1100 |

600

- 1250 |

800

-1500 |

| Thickness

range [micron] |

25

- 100 |

25

- 150 |

25

- 150 |

| Die

[Spiral type] [mm] |

250 |

250

/ 300 |

250

/ 330 |

| Nip

Roll Size [mm] |

1300 |

1400 |

1700 |

| Winder |

Surface |

Surface

- Semi Auto |

Surface

- Semi Auto |

| Connected

load [KW] |

102 |

148 |

196 |

| Floor

Space [Mtrs] |

12.5

x 8 x 8[H] |

12.5

x 8 x 10.5[H] |

15

x 8 x 10.5[H] |

|

|

|

|

||