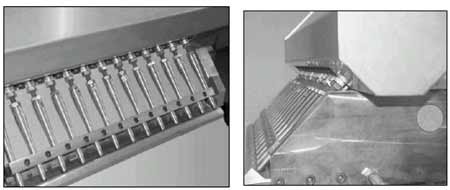

The expansion elements are made of a special alloy which are differential elements and which are controlled contrary: one part of the element expands, the other part contracts. Controlled via energy optimised solid state heat pump Elements.

Technical data’s taken the element: P/40.70.10 as an example:

(Expansion element - p/ 40 mm width, 0,7 mm range. Version 1.0)

* adjustment range: 700 µm (-300 µm to +400 µm,compared

with the element)

* width: 40 mm

* energy consumption at 0 µm : 0 W

* energy consumption at max.: 75 W

* reaction time: time for adjustment min.- max.:approx. 300 sec

* energy consumption fan: 1,2 W continuously

* manual adjustment without clearance

* thermal separated from the die body

* closed temperature control circuit

• wide adjustment range - a new film thickness in few minutes

The range - measured at the lip gap - is 700 microns. An automatic change

of the lip-gap is possible without manual adjustment, during production

Therefore only few minutes are necessary to change from a 300 microns

film production to a 700 microns production - just by entering a new gap

distance in the operator station - the lip will move automatically to

the given gap. This happens parallel across the die, and consequently

the system remains stabile

• high accuracy

absolute controlling: the deviation measured on the thickness control

device respectively the set value will be adjusted exactly.

Within few seconds only the expansion is exact on the set value, without

any surging.

Furthermore the system is not thermal influenced because of the thermal

separation to the die body.

• Short reaction time

There is no overheating of the elements and they are expanding according

to the measured deviation, which is an assumption of a quick adjustment.

A gap change of 700 microns in less then 5 minutes, enables a quick lip

cleaning on cast film lines during the production.

• Very low energy consumption - 0 (zero) Watt heating energy

in working position

In working position the elements need no or very low heating energy.

Power consumption of the element in pre-adjusted working position: 0 W

Continuous fan power consumption: 1,2 W

Energy-optimised controlling via EP solid state heat pump system

This system works independent from the environment temperature.

• Safety in operation

Simple to operate,

Clearance free manual adjustment, no external chilling device is required.

On each expansion element the temperature and the power consumption is

monitored so therefore

every defect respectively error will be indicated.

• Enhanced service life

The low working temperature of the elements (approx. 150 °C) guaranties

a long service life with out any signs of material fatigue. (other elements

on the market need 400 °C).

Beside that the service life of solid state heat pump elements are more than 200.000 hours.

• Economic efficiency and quality of end-products

Our P 2000 automatic flat dies enables the best economic efficiency because

of minimising the material consumption in respect of:

• Less wastage on start up, thickness changing and lip cleaning procedures

• Production within tight tolerances